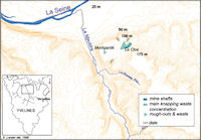

Figure 3: Flint mine of Flins-sur-Seine/Aubergenville a) Geography b) Geology.

Three different regional and local materials were generally used for axe production: tertiary flint, secondary flint and sandstone. Flint can be found mainly in secondary limestone of Senonian and Campanian age, and in the Saint Ouen silicified limestone, which is Tertiary in age. The few axes that are made of limestone occur as grave goods; they are not usable as functional tools, and may have a more ritualistic function.

The Flins-sur-Seine/Aubergenville mine (Yvelines) is located on a plateau overlooking the Seine Valley, near the right bank of the River Mauldre, at an altitude of between 100 and 125m, on a slight slope, orientated south-east/north-west (Fig. 3). The geological substrata consists of limestone and loam of the Upper Bartonian (Ludian) or Lower Saint Ouen Limestone.

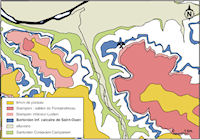

The mine at Flins-sur-Seine was first recognised as a flint-knapping site in 1926 (Silvestre de Sacy et Baudouin 1926 and 1927). Although field-walking by amateur archaeologists has yielded much material, the site was never systematically studied. The raw material used here is Bartonian flint. The flint and the characteristics of the site are very similar to those of the flint mine at Jablines, east of Paris, which was excavated in 1989-1990 (Bostyn and Lanchon 1992). The Service Archéologique Départemental des Yvelines first revealed the existence of mine shafts using aerial photography in 2000. Subsequently, a programme of field-walking and geophysical survey was initiated (Bostyn et al. 2002). Two methods were tested: electric resistivity and magnetic susceptibility. Objectives of the survey were to record the extent of the mining areas, and the size of the flint-knapping areas. The results of the combined field-walking and geophysical surveys revealed that the knapping waste covered an area of 15 ha and the mine shafts covered an area of between 3 and 5 ha (Fig. 4). So far there has been no excavation on the site.

Figure 4: Interpretation of the aerial photography showing mine shafts (photo, P. Laforest, Service Archéologique Départemental des Yvelines, development, C. Riquier).

Most of the finds consist of knapping waste, flakes, debris, bifacial pieces and roughouts. Domestic tools are rare, and there are practically no sherds, polished tools or grinding equipment. So this appears to be a specialised extraction and knapping site outside a settlement zone. The nearest settlements are located 1.5km away on the opposite bank of the River Mauldre, on the Epône plateau. This plateau is covered by good-quality agricultural soils and loess; it has been occupied since early Neolithic times, and has yielded evidence of specialised blade knapping.

In the south-east sector (Fig. 5), it is possible to explore possible correlations between the field-walking data, the geophysical data and the aerial views. We have established a strong correlation between the areas of waste product density and of anomalies, which are concentrated in the southern half of the area. Overall, these are also topographically the highest areas, most exposed to erosion. In the north-west sector, where the geophysical data and field-walking data are already available, the geophysical data did not indicate the existence of a mine shaft, but it did show fairly high concentrations of waste products, tools and of roughouts. This appears to be a manufacturing and production area situated outside the areas of flint extraction.

An experimental shaft was dug in 2003 (Bostyn et al. in press). Two of the main aims of this project were to determine the depth of the flint layers, and to estimate the quality. A third aim was to test different tools made of flint, wood and deer antler, which were used to excavate the flint. Slabs of useable flint were quite accessible at 2m depth.

All bifacial pieces, and the tools in the collections, have been studied. Of almost 1000 pieces, 428 were complete bifacial pieces.

An analysis of waste and tools collected from the study area shows that the manufacturing activities at the mine are essentially linked to the production of axes. Very few other tools were found (scrapers, paring knives). In addition, large tools manufactured from wide, thick blanks or flakes, may have been used for activities connected with mining, such as preparing the structural timbers for use in shafts and galleries.

A technological study directed by F. Bostyn and A. Lo Carmine has proposed a chaîne opératoire for axe production. The brown to light beige-coloured, veined flint was excavated as plates from within the Saint Ouen limestone. The flint plates contain cracks and silica-filled cavities and veinlets. Mined plates of flint and previously struck flakes seem to have been used in similar proportions. The following manufacturing stages have been identified: unifacial and unilateral preparation; bifacial and unilateral preparation; bifacial and unifacial preparation; bifacial and bilateral preparation; preforms and axe (Fig. 6). These three latter categories are the most common (82%).

Figure 6: Tertiary flint axe production sequence pieces at Flins-sur-Seine a) Bifacial and bilateral preparation b) Roughout c) Axe (photography S. Oboukhoff, CNRS, Nanterre).

The principal cause of suspension of work on the flint was its poor quality, due mainly to cavities (32%), intrusive cortex (33%) or incomplete silification (15%). Only 46% of the bifacial and bilateral preparations used good-quality flint, compared with 53% for the axes.

The flint nodules studied are between 80mm and 140mm long; some larger nodules of between 150 and 250mm in length were also studied. Overall, the pieces of flint from the first stages of manufacture have larger dimensions, especially when plate material is used. Although such pieces are quite rare on the manufacturing site, they occur much more frequently associated within regional settlements. The large roughouts made by hard hammering, reduced significantly the size of the original flint nodule.

The analysis of the products found in the mine generally show mediocre production quality, both in terms of the raw material used and the technical skills to work it effectively. These results are surprising because they do not seem to correlate either with the time investment in mining the flint, or with the products from the mine.

The Flins-sur-Seine/Aubergenville flint mine exploited Bartonian Tertiary flint for axe manufacture. It is not the only site specialising in this production. Other workshops for making axes using Bartonian flint have been identified in the region along the River Mauldre (Fig. 7). Apects of production from these workshops are identical in many ways to the finds from the Flins-sur-Seine mine, but there is less knapping waste. Flins-sur-Seine has supplied a large amount of waste and roughouts, which provide the basis for a technological study using quantitative and qualitative data.

The large settlement site at Jumeauville appears to have produced axe roughouts in Bartonian flint, as well as polished axes. Located near several polishing stones, natural sandstone blocks, this could be a defended plateau-edge site. It certainly played a role in the diffusion of axes to the west. This regional concentration of similar or complementary sites involved in lithic production (extraction sites, knapping workshops, polishing stones), eventually in relationship with settlements and cemeteries, is considered as a 'mining complex', apparently structured around a central site (Jumeauville).

Figure 8: Polished axes a) Tertiary flint b) secondary flint (photography S. Oboukhoff, CNRS, Nanterre).

Axes found from the outside the mine are more regular and sometimes have bigger dimensions (Fig. 8a). Products from the mine are mostly irregular and the longest pieces are absent. This observation confirms the status of waste for products found in workshops and mine contexts.

A special technique has been deduced from the presence of small hammers or 'bouchardes' found in some workshops, especially at Jumeauville. Those tools are used in width reduction before polishing, and to save time. They are present in workshops but rare in the Flins mine. An experimental reconstruction has demonstrated the suitability of this technique. Marks observed on reconstructed tools are similar to those found on archaeological hammers.

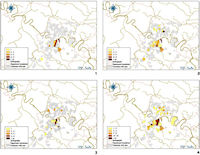

Map work on the distribution of polished axe blades, both finished and unfinished, has been carried out to discover the extent of the axe distribution, regionally. This work is centred mainly on the counties of Yvelines and Val d'Oise; it also extends towards the west and the south-west (Fig. 9).

Figure 9: Distribution map for tertiary flint 1. Bifacial preparations 2. Roughouts 3. Axes 4. Polished axes. (DAO C. Riquier).

In terms of operative stages, the axe distribution maps show the following:

The above evidence strongly suggests that, on a regional scale, roughouts were exported from the manufacturing sites.

Secondary flint workshops and mines are located along rivers and streams, and on the slopes of broad and small valleys, such as the Seine valley. Along the Mauldre river, at Maule (Yvelines), some mine shafts, found under a Merovingian cemetery, have been excavated (Simon 1986). Two radiocarbon dates obtained from material found in the shafts indicate the late Neolithic/Early Bronze Age (Gif 5007: 3460 BP ± 70 over a charcoal sample, Ly 2694: 3630 ± 130 over a deer pick: 2415/1775 cal. BC)

At Villepreux (Yvelines), a flint-knapping workshop was discovered during a survey along the Gally stream in 1983. The geological substrata is made of Campanian Limestone. A rescue excavation was undertaken towards the end of 1999; the results remain unpublished (Samzun et al. 1999). On a surface of 80m², four archaeological levels were identified associated with knapping workshops. No clear extraction evidence was revealed by the excavations, which suggests that nodules, probably taken from the river bed, were being utilised for tool manufacture. Although the associated finds suggest a late Neolithic date, radiocarbon dates obtained from different samples have failed to give a consistent dating. The diversity of the flint waste suggests that kanpping took place on the site. Several categories of nodules are present (whole nodules, struck nodules and uni- and bifacial flakes and splinters). Bifacial pieces and axe roughouts clearly indicate that this was an axe production workshop.

Field-walking has identified other sites along the course of the River Seine, and associated with an anticlineal structure in the Vexin area where the Campanian chalk appears. These sites are located at Guerville (Yvelines), Longuesse and Banthelu (Val d'Oise).

The workshop products vary between the sites. Banthelu provides the most important sample (313), others have fewer pieces: 49 at Guerville, 29 at Villepreux and 24 at Longuesse. Over these four sites, we have obtained a sample of 226 roughouts and fragments, 45 of which are whole pieces. Semi-finished products are quite absent (one axe at Villepreux only). Nodular flint was most commonly used at these sites, together with flakes and plates (Fig. 10). Once again, the main cause of suspension of work on these pieces is the poor quality of the raw material. The product length varies between 100 and 200mm; most of the products are between 125 and 150mm long.

Figure 10: Secondary flint production pieces: roughouts and bifacial preparations. 1. Villepreux "Station d'épuration", 2, 3. Guerville "Saint-Germain-de-Secval" , 3, 5. Banthelu, 6. Longuesse "Station d'épuration" (photography S. Oboukhoff, CNRS, Nanterre).

The chaîne opératoire is rather similar to that of the tertiary flint axes. The first working of the nodule is carried out in order to regularise it. When knapping the roughout, and producing bifacial edged flakes, the irregular shape of the nodules produces a much greater volume of waste material when compared with plates of equivalent size.

The roughouts tend to be associated with the production sites whereas the polished axes, which do not occur at the production sites, are more commonly found on the settlement sites. In fact, the corpus of 239 complete polished secondary flint axes are all from settlement sites and not from knapping sites. Reworked broken polished axes made from secondary flint are as common as undamaged polished axes. This might indicate a concern to conserve the raw material, and to prolong its useful life, by recycling it. Indeed, in many cases, broken ground and polished flint axes are reused for a similar function (axes, chisels or other cutting tools). There is strong evidence to suggest that broken or damaged cutting edges (blades) were reground to form new cutting edges. The butt and edges of the axe were adjusted so that the axe fitted its new handle. Sometimes, the blade is entirely recut, and very little of the original tool is recognisable. Consequently, it is difficult to estimate the number of recut and repolished blades. Polishing erases the previous traces of knapping, grinding and work wear.

The end products (reworked axes) tend to be around between 70 and 200mm long, and occasionally up to 310mm long. The major part of the polished section of the axe is between 70 and 160mm long, although some parts are as long as 260mm.

In some cases, broken axes are used for a completely different purpose. We observed that some secondary or tertiary flint blades (rough-outs or polished axes) had a heavy use-wear (lustre) on the cutting edge. We proposed that these blades were not used solely for cutting wood but may have been used with clay/silt (Beugnier 2000; Bostyn et al. 2003).

The first stages of preparation are concentrated at the workshops (Banthelu, Longuesse, Villepreux and Guerville). The roughouts are mainly distributed on a regional scale, but clearly concentrated beside mines and flaking workshops (Fig. 11). The distribution for final products, axes and polished axes, is consistent over the study area.

Figure 11: Distribution map for secondary flint 1. Bifacial preparation 2. roughouts 3. axes (DAO C. Riquier).

Other materials, such as sandstone, have also been used locally for axe production especially a variety of sandstone rich in quartz or orthoquartzite (Fig. 12). This material is present in Tertiary Stampian Beds across the whole of the study area. This sandstone was also used during the Mesolithic period to make bifacial pieces (adzes and pickaxes) in the Montmorencien industry. Sandstone axes represent 10% in overall relative frequency; they generally occur as polished axes and are rarely reused. Roughout sandstone axes are very rare. Knapping, hammering and polishing processes are involved for the production of sandstone axes. Their morphology is egg-shaped. Some polished axes are reshaped, others are reused as picks or wedges. No workshop for sandstone axes has been found in the study area, but one has been reported from a Neolithic settlement to the south, on the Beauce plateau, at Auneau.

© Internet Archaeology/Author(s) URL: http://intarch.ac.uk/journal/issue26/12/2.html

Last updated: Wed Jul 1 2009