In the next case study we will draw on another contemporary, and potentially disruptive, technology known generically as additive manufacturing. This technology again prompts us to re-engage with some of the core concepts of virtual archaeology, emphasising the fluidity of the term and the continued relevance of the conceptual framework that underpinned its initial use. The case study of additive manufacturing helps to demonstrate that, beyond its association with specific technologies, the spirit of virtual archaeology provides a mechanism for (re)negotiating the use of any technology in archaeological practice. Unlike RTI, additive manufacturing is based upon technologies that are currently unfamiliar to the majority of archaeological researchers. As such we can expect that the way in which archaeologists come to control the development of this technology will probably be different. Having said that, as with computational photography, the application of additive manufacturing to heritage studies began with some engineers using digital models of a historic monument to test their technology. Possibly the earliest extant archaeological example is an approximately 4cm-wide 3D print of the Byzantine church of Hagia Sofia, Istanbul, which was produced by researchers in MIT in 1995-6 (Krassenstein 2014).

Currently additive manufacturing is being popularised by consumer 3D printing and rapid prototyping, which have both been experiencing a great deal of hype, promising, for example, to 'democratise archaeology' (Hall 2016). However, additive manufacturing actually has an effective history of several decades of development (see Hull 1986), and now encompasses a set of mature technologies that have long since passed through the typical hype cycle and are in widespread industrial use (see Basiliere and Shanler 2014). At a very high level, the huge array of available additive manufacturing technologies can be loosely classified into three categories (Lipson and Kurman 2013). Selective extrusive printers in essence squirt, squeeze or spray pastes or powders through nozzles, syringes and funnels of all sizes to build up objects by depositing materials in layers. Selective binding printers, by contrast, fuse, bind or glue materials together, again in layers. The aforementioned technologies can, in one sense, be seen as producing analogue printing or additive manufacturing outputs using digital controllers. Currently at the cutting edge is true digital assembly, using pre-manufactured physical objects. We can think of them as Lego blocks. However, precise assembly of billions of small physical voxels made in different and multiple materials remains a huge computational and fabrication challenge. Of course, hybrids deploying multiple and different kinds of print heads, offering a variety of fabrication methods, could also be configured.

Lipson and Kurman (2013, 265) summarise the evolution of additive manufacturing as three stages of gaining control over physical matter; control over geometry, composition, and behaviour. First is an unprecedented control over the geometry, or shape, of objects. 3D printers can already fabricate objects of almost any material in any shape. Next is control over the composition of matter. We have already entered into this phase where we go beyond just shaping external geometries to shaping the internal structure and composition of materials with unprecedented fidelity, with the possibility of printing multiple materials including multiple entangled material components that can be co-fabricated simultaneously (e.g. Vaezi et al. 2013, Vidimče et al. 2013). The final stage is control over the behaviour of materials, where they envisage programmable, so-called 'smart', digital materials – made of discrete, discontinuous units – which are designed to function in a desired way, such as hard, smooth, translucent, vase-shaped, in graded shades of grey, cream and ochre, perhaps even embedded with different inclusions and voids. Voxel-based printing affords the notion of different types, shapes and sizes of voxels (Hiller and Lipson 2009). We can imagine a library of archaeologically defined material voxel types, enhancing the context composition descriptions typically found in archaeological field guides.

However, we need to take a step back for a moment, as it is control over shape that currently provides the all-important bridge between historical and existing 3D modelling formats and our ability to repurpose them as 3D printed physical objects. Existing point clouds, digital terrain and solid models, indeed any system that can output STL format files, can be 3D printed. For example, digital terrain models of archaeological earthworks captured using Lidar have already been 3D printed for exhibition purposes in the UK (NewForestArchaeology 2015). Various other terrain models have been extracted from GIS systems for 3D printouts in South Africa (Agrawal et al. 2006), while geologists in Germany (Loewe et al. 2013) and more recently archaeologists in France (Tronchère et al. 2016) have attempted to 3D print stratigraphy. Underwater archaeological sites recorded using photogrammetry and sonar are also becoming available as full colour 3D prints (e.g. McKenzie 2016). Museum artefacts too are being cloned using this technology (Neumüller et al. 2014). In addition to the Hagia Sofia model already mentioned, other re-imagined solid models, such as the Old Minster, Winchester, which was first developed and animated in 1984, may be rediscovered in physical 3D instantiations (see Reilly et al. 2016). Even the enigmatic immaterial traces of the victims of Vesuvius at Pompeii are being (re)materialised as 3D printed artefacts (Reilly 2015). Although all these examples produce relatively small solid physical objects made in a single material, they nevertheless communicate in a very tangible fashion.

All the archaeological examples we have outlined so far can be categorised as Tronchère et al. (2016, 9) aptly put it as 'archaeology in plastic'. However, makers and manufacturers can fabricate all manner of things using many different other materials, from bread dough, chocolate, and other food-based materials, to gypsum, sand, soil, terracotta, concrete, metal alloys, as well as many plastics and polymers. The list continues to grow. These very different materials enable a wide spectrum of applications across a very broad range of scales (see Lipson and Kurman 2013).

We can point to an expanding set of projects that demonstrate the feasibility of large-scale additive manufacturing involving a range of different materials that are directly applicable to the heritage sector. For instance, Midwest Studios 3D printed a highly detailed architectural model for a Carmelite monastery, using the architect's (McCrery 2014) CAD files, which they designed and subsequently built in classic French gothic style, including flying buttresses, for a growing community in Wyoming, USA. Moving into human-scale applications, Swiss architects (Hansmeyer and Dillenburger 2014) created and 3D printed an ultra-modern, gothic-like immersive space dubbed the 'Digital Grotesque'. This room-like structure was assembled from 64 massive separate printed sandstone-like parts, containing 260 million surfaces printed at a resolution of a tenth of a millimetre. The 11-ton room took a month to print but only a day to assemble. The construction industry has printed multi-storey residential and office buildings, complete with interior and exterior architectural decorations, and commercial offices using giant fabricators (e.g. Lim et al. 2012; Cesaretti et al. 2014). On the horizon are new building materials and manufacturing technologies. For instance, both European and North American space agencies are exploring the feasibility of building future moon-bases using fabricators exploiting local materials; in other words using the regolith or lunar soil. Of course these projects require the use of terrestrial simulants – materials with the same necessary material properties (e.g. Balla et al. 2012; Cesaretti et al. 2014).

The potential of additive manufacturing, primarily in the form of 3D printing and rapid prototyping, for virtual heritage and archaeological reconstruction is therefore technologically well established, although there is no consensus yet concerning in which heritage situations this technology is appropriate. At present, for example, an important debate is unfolding around the ethics of 3D restoration versus preservation of the physical remains of the Roman city of Palmyra, Syria, which was extensively damaged during the recent conflict in the region (see for example Jenkins 2016; Jones 2016; Nodjimbadem 2016). However, let us now become more speculative, more aspirational, and explore some facets of additive manufacturing pertaining to materialisations of virtual archaeologies that might come to be.

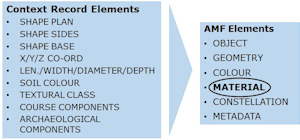

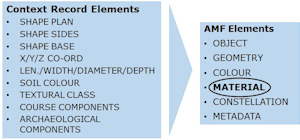

As additive manufacturing evolved from producing primarily single-material, homogeneous shapes to producing multi-material geometries in full colour with functionally graded materials and microstructures, it created the need for a standard interchange file format that could support these powerful new features. The response was the Additive Manufacturing File format (AMF), an open standard for describing objects for additive manufacturing processes such as 3D printing (AMF ASTM 2014). What is striking about the AMF format is that it encapsulates the typical recording sheet used on a modern archaeological excavation (Figure 5), but does so in much finer spatio-compositional, that is in both macro-morphological and micro-morphological, detail. If we could recast our recording method to generate contexts described in an AMF-like format, we suggest that archaeology would be a step closer not only to aligning the virtual and physical worlds, but also towards the possibility of rematerialising archaeological entities encountered in the field.

What is to stop us from recording our excavations in such a way that they can be refabricated in fine-grained, multimaterial fidelity? Current methods are clearly deficient. Here, by the way, we are not suggesting that all excavation should be 3D printed. We submit that if we recorded in such a way that we could rematerialise, or refabricate, our excavations in physical multimaterial 3D, then we would have improved substantively our best practice. Some will argue that current procedures are adequate for current needs. We counter that in a uniquely destructive discipline, are archaeologists not ethically obliged to strive for superior recording practices, to anticipate, as Christopher Witmore (2009) has argued, the needs of future archaeologists and myriad other interest groups?

Glimpses of additive archaeology, which is just one emerging virtual archaeological practice materialised through additive manufacturing, can already be discerned in the work of soil scientists and archaeologists conducting virtual excavations involving both scientific visualisations and 3D printing. For example, using a combination of Computed Tomography (CT) and 3D printing, soil scientists now have the ability to explore something as intricate and detailed as the structure of soil, and set up multiple experimental investigations (Otten and Falconer 2014). Similarly, archaeologists can now disaggregate and reaggregate non-intrusively a coin hoard found in ceramic pots near Selby in the north of England. The CT data, which can be resolved down to two microns, were processed to extract the 'objects' of interest (i.e. the morphology of the coins). One set of objects were incorporated into a CGI animation providing a detailed contextual but quite constrained linear exposition of the assemblage. This fine detail was exploited to isolate and identify individual coins as images and an animation (Miles and Cox 2013). It was also possible to apply pseudo-RTI visualisations, and generate fair, but not yet geometrically identical, 3D prints of the coins, thereby allowing for novel multi-threaded narratives via individual hapto-visual inspection (Miles 2012; Miles et al. 2016, 40).

Internet Archaeology is an open access journal based in the Department of Archaeology, University of York. Except where otherwise noted, content from this work may be used under the terms of the Creative Commons Attribution 3.0 (CC BY) Unported licence, which permits unrestricted use, distribution, and reproduction in any medium, provided that attribution to the author(s), the title of the work, the Internet Archaeology journal and the relevant URL/DOI are given.

Terms and Conditions | Legal Statements | Privacy Policy | Cookies Policy | Citing Internet Archaeology

Internet Archaeology content is preserved for the long term with the Archaeology Data Service. Help sustain and support open access publication by donating to our Open Access Archaeology Fund.