In order to classify the ceramic assemblage from Mahurjhari primarily on the basis of the techniques used in their manufacture, first it is necessary to define each stage of the manufacturing process and understand the relevant variables we will record for those stages. It is worth noting here that all of these variables and attributes can be recorded visually without the use of more scientific techniques (such as microscopy or chemical sourcing). While such techniques can undoubtedly provide even more valuable information, their application was beyond the means of the present study. Several stages of production are common in the manufacture of all pots. These include the selection and preparation of the clay and other raw materials, the forming and shaping of the vessel, the pre-firing finishing of the vessel surfaces, which can sometimes include various methods of decoration, the drying of the vessel, the firing process, and, finally, any post-firing treatment that might be applied, which again can include various forms of decoration. For an overview, see Orton et al. (1993).

Other than the pre-firing drying, all of these stages of production leave visible and discernible traces on the pots and pottery fragments. These traces can be translated into technical attributes that can be recorded and described. Stages of production and traces of the manufacturing process that can be discerned visually are as follows:

Equipped with an awareness of the manufacturing sequence, the first stage in our analyses of the assemblage from Mahurjhari was to record these attributes for all individual sherds. Pre-defined metrics with reference to commonly agreed 'standard' frames of references, such as Munsell colours and inclusion sorting charts (detailed below), were used in order to ensure that data were recorded as systematically and consistently as possible. This is, of course, with the caveat that human error and the subjectivity of visual inspection mean that some data will inevitably be missed. We also recognise that there are many additional variables that could be recorded, and various different scales of resolution at which this could be carried out. The variables and the quantitative and qualitative attributes used in this study are summarised in Table 2. Coding sheets and detailed descriptions of the attributes and variables that we recorded are presented in the Appendix. This detailed Appendix has been created initially in order to allow a non-specialist to use the table. It was conceived as a fairly exhaustive list of attributes and variables, together with descriptions that can function as a check list to ensure that every potsherd was recorded in as much detail as possible. Indeed, the first stage in the recording of the assemblage was undertaken by Namrita Biswas, a PhD student at the Deccan College of Pune, a non-specialist with no formal training in pottery analyses.

| Categories of recording | Details of individual features recorded |

|---|---|

| ID Sherd no. | Individual identification number applied to each sherd |

| Context information | Details of the trench, square, context/layer, and/or feature in which the individual sherd was found |

| Fabric colour | Details of the sherd core as it appears after a fresh break (its Munsell colour, whether there are different coloured margins, whether these are diffuse), details of any margins towards the exterior surface of the sherd (Munsell colour, whether or not they are diffuse), details of any margins towards the interior surface of the sherd (Munsell colour, whether or not they are diffuse), details of the exterior surface (Munsell colour, whether the colour is patchy, whether it is visible in section), details of the interior surface (Munsell colour, whether the colour is patchy, whether it is visible in section) |

| Fabric texture and feel | The hardness, ease of fracture, firing environment, feel of both the exterior and interior surfaces measured how, and level of compaction |

| Fabric inclusions | Details of each inclusion type visible in section (its type, colour, size, shape, sorting, and frequency) |

| Surface finish | Details of both the exterior and interior surface finish (coating type, colour, treatment, treatment type, treatment description) |

| Surface decoration | Details of the exterior and interior decoration (decoration type, and decoration description) |

| Description | Sherd type, vessel form, manufacturing technique(s) |

| Vessel size and sherd dimensions | Measurements and characteristics of the rim (type, shape, diameter, % surviving), base (type, diameter, % surviving), thickness (body thickness, rim thickness, neck thickness, shoulder thickness, base thickness), and sherd dimensions (sherd height, sherd width) |

Having recorded this information, the sherds were spread out on a table and grouped according to the repeating combinations of attributes that had been noted during the detailed recording process. In doing so, the potsherds were organised into distinct classes and variants of those classes on the basis of the criteria evident through visual inspection, the most apparent of which were deemed by us to be the most relevant. Groupings (and resulting definitions of classes) were not made on the basis of statistical analyses, though such techniques are, of course, available. Grouping the sherds in this way resulted in the identification of ten ceramic production classes subdivided into twenty-three variants (described in detail below). The main classes were established on the basis of observations made of the paste, shaping, finishing and firing, which were all considered at the same time, while the variants of a class were set up on the basis of the surface treatment and/or the firing mode. The goal here was to identify meaningful variations in the production of pots in order to use these as the bases of our classification — essentially, defining technical pottery groups that attest to 'ways of doing'. As we did not find any complete vessels, we could not identify all the techniques that were used in the manufacture of any single pot. We also defined variants within each major class of production to express the variations that are visible and readily identifiable in terms of treatment of surfaces or firing mode. It is perhaps worth pointing out here that this system does not correspond stricto sensu to that used by earlier ceramic specialists in the development of classificatory systems within the original chaîne opératoire approach. Roux (Roux 2011; Roux and Courty 2016), for instance, suggests organising potsherds first according to their shaping techniques and then according to the fabric groups and the other technical features such as the surface treatment. This was not possible in this study, as the entire shaping process could not be reconstructed for most of the sherds in the assemblage (one of many unfortunate consequences of the discard policy employed on site). Consequently, we opted for a combination of different technical criteria instead of a purely and strictly 'linear' system.

In addition to the definition of chaîne opératoire classes of pottery, the detailed documentation of fabric colour, texture, feel, and inclusions that emerged from the recording of the variables was used to identify and define the different types of fabric that were used to manufacture the Mahurjhari ceramics. These 'Fabric Groups' were identified on the basis of the different compositions of the clay 'paste' used to make the pots, as visible to the naked eye and with the assistance of a ×10 hand lens. To estimate the density and distribution of visible non-plastic inclusions, we used the inclusion sorting chart published by Barraclough (1992), and reproduced by Orton et al. (1993).

We took a hierarchical approach to our definition of Fabric Groups, identifying major groups and a number of variants using principles similar to those used in the definition of pottery classes. Given the nature of previous approaches, it is important here to make clear the distinction between classes of pottery and Fabric Groups. Classes are defined on the basis of the entire process of manufacture, not simply on the basis of the Fabric Groups. They are then subdivided by variations within this overall process (such as similarly formed vessels that differ only in surface treatment or decorative techniques), and are thus, by definition, not the same as the types of clay mixtures that were used in those manufacturing processes. That is not to say that the ways in which different clays were processed to make pots (defined here as Fabric Groups) were not a central part of manufacturing processes. Quite the opposite is true. Rather, it is simply that defining them separately allows for the consideration of pots that were made using similar methods but with clays that were sourced from different places or processed in different ways by different people. Or, to phrase things another way, a class of pottery can be defined on the basis of shared technical attributes linked to steps of the chaîne opératoire (e.g. coarse texture, organic temper, coil made, red slip on exterior surface, polishing, oxidised firing), even if they were made using a variety of different fabrics at the same time. By the same degree, and as we know from wider archaeological contexts, clay from the same source can be used to make pots belonging to several different classes depending on the intent of the potter, potters or workshop; and the preparation of that clay can differ notably with the addition of specific tempers. A useful example of this can be seen in the Near East. Here, a specific type of pottery known as 'Brittle Ware' is found in contexts dating from the Roman to the Abbassid periods. It is characterised by thin-walled cooking vessels produced with an iron-rich sandy clay, with red or black coloured sections and surfaces depending on the firing atmosphere. In terms of its manufacture, this is one single identifiable 'Class' of pottery. However, recent petrographic and chemical analyses have shown that several fabric groups were used in its manufacture (Vokaer 2011). This realisation has, in turn, led to the identification of several workshops spread throughout North Syria.

As a third stage of analysis, we organised the potsherds within each class-variant into different morphological categories to develop an open and flexible typology of form that can incorporate new types as future discoveries are made. To this end, we make a distinction between restricted or 'closed' shapes (e.g. pots, and jars) and unrestricted or 'open' shapes (plates, dishes, cups/lids, bowls), both of which indicate very different functional uses. In distinguishing between these shapes, we make reference to the system of metrics and proportions presented by Balfet et al. (1983) and Shepard (1965). According to these definitions, 'open' or unrestricted shapes can be defined if the diameter at the opening (or mouth) of the vessel is equal or higher to the utmost/maximum diameter of the body. They are wider than they are tall. Their diameter equals or exceeds their height. In 'closed' or restricted shapes the diameter of the body of the pot narrows between its maximum diameter and its opening. Even if the opening of this type of pot flares out above this smaller diameter, we define it as a 'closed shape' as it is taller than it is wide.

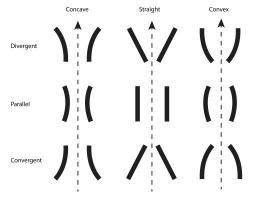

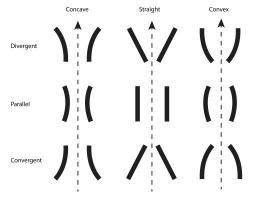

Nevertheless, and despite the existence of such established frames of reference, it has not been possible to categorise some vessel shapes because we did not encounter any complete profiles. Our categories ('vessel types') have thus been defined on the basis of a various morphological characteristics. These include: the presence or absence of a neck, the orientation of the sides of the vessel using definitions established by Gardin (1976) (Figure 5), and the shape and orientation of the rim. Rim types were recognised as a significant diagnostic feature that we used to define additional variants with each morphological 'type' of vessel.

Having defined the different ceramic classes in this way, the final stages of analyses were to assess the numbers of each class in relation to each other stratigraphically in each trench. This began with the ceramics from Trenches C and F because they had already been dated. It was then possible to use the seriated pottery from Trenches C and F as a relative means to date the ceramics found in other trenches and, by extension, establish the chronological sequence of those trenches. With chronology thus established, the seriation of the ceramics in each trench opened up the possibility of looking at how methods and modes of ceramic production varied and changed over time across the site. Of course, it is recognised that the level of results, and what we can say on the basis of this analysis, is directly affected by the size of the assemblage and the quality of our understanding of the depositional contexts in which the ceramics were found. It is with these constraints in mind that we present the results below.

Note, as established above (Table 1), ceramics were encountered in all trenches. However, due to various issues relating to the excavation and recording of Trench E, the ceramics from that trench have been omitted from this study. Sherd counts and associated data are provided in datasets that can be accessed online (Lefrancq and Hawkes 2019c; 2019d) should further study be carried out.

Internet Archaeology is an open access journal based in the Department of Archaeology, University of York. Except where otherwise noted, content from this work may be used under the terms of the Creative Commons Attribution 3.0 (CC BY) Unported licence, which permits unrestricted use, distribution, and reproduction in any medium, provided that attribution to the author(s), the title of the work, the Internet Archaeology journal and the relevant URL/DOI are given.

Terms and Conditions | Legal Statements | Privacy Policy | Cookies Policy | Citing Internet Archaeology

Internet Archaeology content is preserved for the long term with the Archaeology Data Service. Help sustain and support open access publication by donating to our Open Access Archaeology Fund.