This class of pottery was made predominantly using Fabric Group 1, and is characterised by a paste of medium texture and the presence of sand-like temper. String-cut marks at the external surface of the annular plain base and parallel horizontal striations on both the interior and external surfaces of bodysherds suggest use of a fast wheel to manufacture this class of pottery. However, surviving sides and bases also exhibit a number of irregularities on the surfaces and slight distortion of the whole vessel. As has been demonstrated in other archaeological contexts in Greece (Rückl and Jacobs 2016) and north-east India (Sharma et al. 2017) the usual signatures of fast-wheel production can also be indicative of wheel-coiled techniques that use a slow wheel to finish the shape. The size of potsherds in this assemblage did not allow us to solve the question of which techniques were used in the production of this class.

This class of pottery was fired in an oxidising atmosphere, evidenced by the red colour of the fabric visible in section, while the presence of a slightly darker core indicates that this firing process was not well controlled. Interior and exterior surfaces are reddish in colour (Munsell 5YR-6/4, 5YR-5/6, 10R-6/4, 10R-5/6, 2.5YR-6/6) with slight variations evident in the treatment of the surface (see below). In addition, some sherds display small white concretions (possibly fragments of chalk) on both surfaces. This may be due to post-depositional effects. Three variants were identified on the basis of decorative techniques.

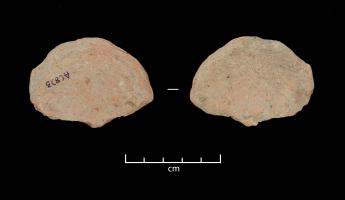

This variant comprises the majority of the potsherds belonging to Class 1. Other than occasional white concretions on both surfaces, no surface treatment is evident. Only one distinct vessel form has been identified (the majority of sherds being undiagnostic bodysherds). Vessels are bowls or cups characterised by divergent and straight or convex sides (see Lefrancq and Hawkes 2019b). The rim is thinned and round. Both surfaces exhibit corrugations owing to the wheel-thrown or wheel-coiled techniques used. For vessel forms, see Lefrancq and Hawkes (2019b, plate 1).

Only two sherds belong to variant 2: a rim-sherd of a jar with an undetermined diameter, divergent and straight sides and a round rim; and a highly eroded fragment of an annular, or ring-shaped, base. Both are characterised by the use of a different fabric (Fabric Group 2) than those belonging to Class 1 variant 1. Fabric Group 2 has a finer matrix (see Lefrancq and Hawkes 2019a). However, some horizontal voids typical of organic tempers are visible on surfaces. This could suggest the addition of organic material such as straw during the firing process. As was the case with variant 1, the surfaces are irregular with occasional white concretions. No other decoration is noticed. For vessel forms, see Lefrancq and Hawkes (2019b, plate 1).

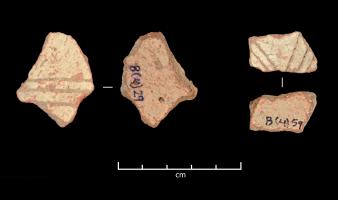

The fabric and fashioning techniques used to make vessels belonging to this variant are the same as those noted for variant 1. Only a few bodysherds were found. The main differences between this variant and variants 1 and 2 occur during later stages of the chaîne opératoire (see stage 3 of the manufacturing process, as described above) in the presence of an incised decoration (parallel lines combined or not with oblique lines) on the external surface, and the application of light whitish slip (7.5YR-7/2 pinkish grey, 7.5YR-8/2 pinkish white) on both surfaces. This slip is better preserved on the external surface. No rim sherds have been found but the orientation of the sides of these bodysherds suggest a restricted shape. This contrasts with examples of Class 1 variant 1, where unrestricted shapes predominate. For vessel forms, see Lefrancq and Hawkes (2019b, plate 1).

Internet Archaeology is an open access journal based in the Department of Archaeology, University of York. Except where otherwise noted, content from this work may be used under the terms of the Creative Commons Attribution 3.0 (CC BY) Unported licence, which permits unrestricted use, distribution, and reproduction in any medium, provided that attribution to the author(s), the title of the work, the Internet Archaeology journal and the relevant URL/DOI are given.

Terms and Conditions | Legal Statements | Privacy Policy | Cookies Policy | Citing Internet Archaeology

Internet Archaeology content is preserved for the long term with the Archaeology Data Service. Help sustain and support open access publication by donating to our Open Access Archaeology Fund.