Cite this as: Adams, S., Craddock, P., Hook, D., La Niece, S., Meeks, N., O'Flynn, D. and Perucchetti, L. 2024 The Pulborough Gold Torc: a 4th to 3rd century BCE artefact of European significance, Internet Archaeology 67. https://doi.org/10.11141/ia.67.16

Torcs are prominent rings worn around the neck, usually penannular in shape, with the opening at the front defined by distinctively shaped terminals. They are occasionally depicted on pre-Roman coinage, and in classical sculpture and texts, adorning the necks of Ancient Britons and Gauls (e.g. Éluère 1987). Thus, they have become synonymous with the identity of the inhabitants of France, Belgium and Britain in the Iron Age (Joy and Farley 2024 , 544-45) but their distribution reaches far across Europe 'from the Atlantic to the Black Sea and from the Baltic to the Mediterranean' (Hunter 2015, 96; Joy and Farley 2024, 545, fig. 22.1). Torcs are impressive pieces of metalwork, made from gold, silver or copper alloys, or sometimes iron and very occasionally lead. They are attention-grabbing items of jewellery that delineate the head of the wearer and beguile the viewer, captivating the eye and capturing the imagination in museum displays.

The term torc is applied to examples from the Middle Bronze Age and Iron Age periods but they are most typically associated with the latter, being found adorning the dead in richly furnished graves in Western Continental Europe from the 6th century BCE and in hoards into the 1st century CE (Armbruster 2021; Joy and Farley 2024, 544-45). In Britain and Ireland, they are infrequent finds discovered as single objects or in hoards or watery deposits but rarely in graves, and the variation in form is considerable. Despite their infrequency, torcs make up the majority of gold and gold alloy finds from Britain and Ireland from the 5th century BCE until the introduction of gold coinage in the later 2nd century BCE. Their form varies considerably and the term has been used to cover both large and small versions, twisted and tubular forms, solid rings with removable segments and multi-strand wire forms. Penannular torcs have expanded terminals, typically larger than the ring and often of a different shape and form to the latter, while annular forms have expanded or elaborated sections.

The dense clusters of torcs found at Snettisham, Norfolk, and the hoard found at Ipswich are unrivalled even decades after their first excavation, owing to the unique concentrations within these deposits (Brailsford and Stapley 1972; Stead 1991). Fragments of gold alloy objects that appear to be parts of torcs are increasingly being found by metal detectorists and reported to the Portable Antiquities Scheme, where they are recorded and assessed under the requirements of the Treasure Act 1996 and Treasure Designation Order 2002. Occasional instances of complete or relatively complete gold alloy torcs have also been found and reported in this way. Examples include the complete torc from Newark, Nottinghamshire, found in 2005 (PAS ID: DENO-4B33B7), the terminal of the Sedgeford torc found almost 40 years after the rest of the object (BM 2005,1103.1 and BM 1968,1004.1; Brailsford 1971), and the torcs and bracelet hoard found in Leekfrith, Staffordshire, in 2016 (Figure 1.2; The Potteries Museum and Art Gallery, Staffordshire: STKMG:2018.LH.10.1-5; PAS ID: WMID-FD08D9; Farley 2017; La Niece et al. 2018). The Pulborough torc, found in 2019 by a metal detectorist near Pulborough, West Sussex, is another such example and is the surviving half of a larger symmetrical torc of 4th to 3rd century BCE form (PAS ID: SUSS-24FBDB; Adams 2021).

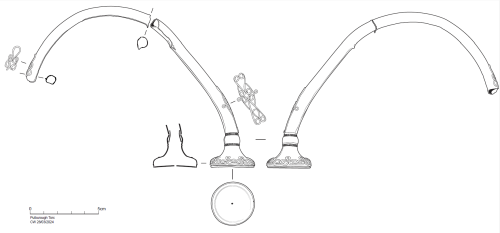

The Pulborough torc is made from gold alloyed with silver and a little copper (see Section 4), worked into a tubular neck-ring and one remaining buffer-shaped, hollow terminal, both adorned with simple, sinuous filigree decoration (Figures 1.1, 2.1 and 2.2). The opposite terminal and a long section of neck-ring are missing as the result of an old break. A more recent break has torn this surviving torc half into two pieces. The external simplicity of the design belies the complexity of the construction, the torc being compiled from several pieces and incorporates sheet working, forging, casting and soldering techniques, all typical of the period. The wire is hand-made using a block-twisting technique that fell out of use in the later first millennium CE and was usurped by drawn wire, which had been adopted after the Roman period (Whitfield 1990; Ogden 1991; Craddock 2009, 376). The percentage of gold in the alloy is towards the lower end of the range for the period, with relatively high silver and a few per cent of copper (Table 1), but is compatible with other first millennium BCE sheet and filigree-decorated goldwork from Europe. Gold buffer terminal torcs are relatively rare in comparison to copper-alloy examples in Europe. In Britain and Ireland copper-alloy versions are even rarer than gold ones, such as the example from the River Medway near Aylesford in Kent and the fragment from Lichfield, Staffordshire (Maidstone Museum MNEMG 1990.53; Fox 1958, 66, pl. 26b; Jope 2000, 234, pl. 32a-b; Gilmore 2019; PAS ID: WMID-62A518). The form is well known from the Marne region of France but buffer terminal torcs have also been recovered from elsewhere in France, as well as Austria, Belgium, Bulgaria, Czechia, England, Germany, Ireland, Italy, The Netherlands and Switzerland (Jacobsthal 1944; Kruta 2004; Schwab et al. 2018; Warmenbol 2018; Armbruster et al. 2021). The aforementioned Leekfrith gold torcs and bracelet are thought to be imports from Germany or France between c. 400-250 BCE (Farley 2017; PAS ID: WMID-FD08D9). The gold examples vary considerably from each other in the way they are made and decorated, thus rendering each unique. Examination with high-powered digital microscopy, scanning electron microscopy and radiography have revealed the details of the design and manufacture of the Pulborough torc showing it is constructed from several pieces, was well-worn and subject to a number of phases of damage, leaving the surface highly scarred.

The two fragments of the Pulborough torc were discovered by a metal detectorist while detecting an area at the edge of a stream that is usually boggy but at that time had dried out. The pieces were found at a depth of 0.3m below the ground surface. The land rises up from the stream on either side and is arable on one side of the stream and pasture on the other. This discovery was reported to the local Finds Liaison Officer in 2019 as a potential Treasure Case (Treasure case: 2019 T560). Following examination of the artefact at The British Museum it was confirmed that the two pieces belong to the same object, made from more than 10% precious metal and over 300 years old. A report was submitted to the coroner for East Sussex who confirmed this object qualified as Treasure under the stipulations of the Treasure Act 1996 and Treasure Designation Order 2002. Following valuation by the Treasure Valuation Committee, the torc was acquired by The Sussex Archaeological Society for the Barbican House Museum, with grants from the Art Fund, the Arts Council England and Victoria and Albert Purchase Grant Fund, The Headley Trust Museums Archaeological Acquisition Fund, and with public support. Subsequently a paper argued that the torc was of recent manufacture (Machling et al. 2023). This claim has been addressed and refuted in this article.

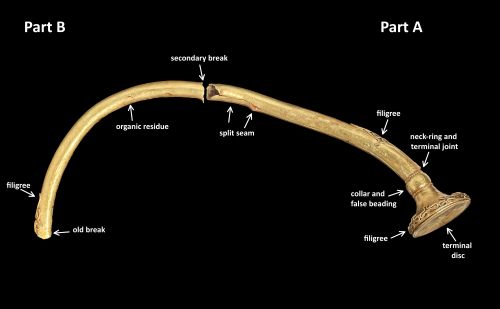

Only half of the original length of the torc is present and this has been broken into two further parts across the neck-ring. Part A consists of one buffer-shaped terminal and part of the neck-ring, both decorated. Part B is slightly shorter in length and has been torn from Part A. It consists of part of the neck-ring with a small portion of wire decoration at one end. It is broken across this adorned area, which allows the original size of the torc to be estimated because it coincides with the original mid-point at the back of the neck-ring where decoration often occurs on copper-alloy versions (the buffer terminals being located at the front). The other half of the neck-ring and second terminal are missing. The neck-ring and terminal are made from wrought gold alloy sheet and are decorated with twisted wire soldered to the sheet surface in curvilinear designs (Figures 1.1, 2.1 and 2.2). Based on other buffer-ended torcs it is assumed the original design had two similar symmetrical terminals. The two tubular pieces can be partially refitted along part of the torn edge; the torsion during fracture has distorted the end of each piece but nothing is missing (Figure 3.1). Part A is 118.2mm long. The diameter of the terminal is 28.7mm and the maximum external diameter of the neck-ring tube is 8.2mm. This piece weighs 39.68g. Part B is 94.1mm long. The maximum width of the neck-ring tube is 7.2mm and the weight is 17.86g, giving a combined total weight of 57.54g. The estimated diameter of the complete torc is at least 135mm but comparison with other buffer terminal torcs shows the terminals may be positioned at variable distances from one another to create a smaller or wider opening at the front, so the space for the neck of the wearer was probably close to 150mm or more and the complete weight would have been in the region of 115g.

Hollow, tubular torcs in Britain and Ireland cover a broad spectrum of sheet metal examples, from versions with wide tubes made from thin sheet to versions with narrower tubes made from thicker sheet. These include several from Hoard F, Snettisham, Norfolk, that are typologically distinct from each other (e.g. F.43: BM 1991,0501.29, F.58: BM 1991,0501.25, F.61: BM 1991,0501.164 and F.62: BM 1991,0501.30; Stead 1991, 448-51, pls 1-3; Farley and Joy 2024). These tubular forms contrast with the dominant twisted or plied torc forms from this region, which have two or more strands of gold twisted and plied together to form the neck-ring, often with loop-shaped terminals and variations of this design (Éluère 1987, 34; Hautenauve 2005, 88-105). The shape of the Pulborough torc, with a smooth band and buffer terminals, is a known form, more common in France than England and more typically, though not exclusively, reproduced in bronze rather than gold. Examples of gold buffer terminal torcs have been reported through the Portable Antiquities Scheme, including the Caistor torc from Lincolnshire and the Leekfrith torc, Staffordshire (Figure 1.2 and Figure 3.2; PAS ID: NLM-605352; Joy 2013; PAS ID: WMID-FD08D9; La Niece et al. 2018). Both have buffer terminals with raised collars below but they all have solid bodies. The latter hoard also contains smaller buffer-like terminal variations that may be described as thistle-shaped. The buffer terminal shape is generally perceived as a 4th-century design in France and Germany, with a concentration of bronze versions in the Marne department and Paris Basin (Stead and Rigby 1999, 67-8; Baray 2016). Gold versions have been dated to the 4th to early 3rd century BCE but some examples are considered to be as early as the 5th century in the regions of the Rhineland, Bohema and the Po Valley, Italy (Éluère 1987, 35; Echt et al. 2011 , 44; Nordez et al. 2019, 39). The filigree decoration also has antecedents in the late 6th to 5th century BCE.

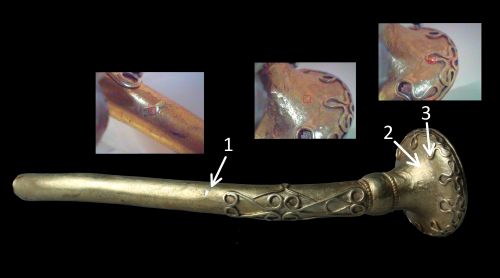

The surface composition of the metal used to make the torc was analysed on two occasions. Both sets of results confirmed that all the components were made from gold containing silver and a little copper. The initial analytical survey, in 2020, of the metal using an Artax X-ray fluorescence (XRF) instrument on uncleaned surface metal revealed a composition of approximately 61-63% gold, 35-37% silver, with the rest being copper. These measurements were taken at various locations on the torc. In 2021, to confirm the composition of specific components of the torc, three further representative points on Part A were recorded and analysed, again using the same XRF spectrometer. These analyses were also performed on non-abraded surfaces, limiting their accuracy. Thus, the results have been rounded to whole numbers (Table 1). The location (Figure 4.1) of each analysed area is as follows:

| Analysis no. | Analysed area | Gold (Au) % | Silver (Ag) % | Copper (Cu) % |

|---|---|---|---|---|

| 1 | Sheet tube of Part A | 56 | 40 | 4 |

| 2 | Sheet terminal of Part A | 61 | 37 | 2 |

| 3 | Wire on terminal of Part A | 58 | 38 | 4 |

Traces of the solder used to affix the wire ornament to the gold tube and gold terminal can be seen on the surface around the wire. Surface analysis of this solder in the first stage of the XRF analysis showed no discernible difference between the composition of this and the wire and gold sheet. No evidence was found of any elements that can be found in some more recent gold solders, such as cadmium and zinc. Contra Machling et al. (2023, 19), despite the similarity between the percentage of gold in this object and late 19th and early 20th century gold alloy jewellery (14 and 15 carat), the major alloying component used in those two centuries was almost invariably copper not silver, quite different from the silver-rich alloy of this torc (Craddock 2009, 371).

The composition of gold alloy torcs from the later first millennium BCE is an area of growing research. Few analyses have been undertaken or published. The majority of published analyses indicate that Iron Age gold objects tend to contain more than 70% gold but the precise details are more complicated (La Niece et al. 2018, 409; Nordez et al. 2019, 45). Data gathered on the design, composition and distribution of gold Iron Age objects from England, Scotland and Wales, published in 2018, showed the gold alloy composition varied chronologically both within and across assemblages (La Niece et al. 2018). Gold alloys with a higher silver content were more typically derived from the final two centuries BCE than earlier periods in Britain but not exclusively so (La Niece et al. 2018, 408-9).

The famous assemblage of torcs and torc fragments from Snettisham attests to the variety of compositions of the gold alloys (Meeks et al. 2014). For example, twisted wire torc fragments F.9a: BM 1991,0501.125 and F.160: BM 1991,0501.192 from Hoard F are similar to the Pulborough alloy composition, with 57.2% gold, 37.1 % silver and 5.7% copper, and 60.4% gold, 35.8% silver and 3.8% copper respectively when analysed using SEM-EDX (scanning electron microscopy with energy dispersive X-ray spectroscopy), whereas other pieces had a much higher gold content (Meeks et al. 2014, table 2). Comparable to this is the surface composition of the terminals and wire of the twisted torc from Sedgeford containing 53% gold, 45% silver and 2% copper (BM 2005,1103.1 and BM 1968,1004.1; La Niece et al. 2018, 419). In contrast, the analysis in the 1960s of the potentially contemporary Knock torc, Co. Roscommon (see Section 5), revealed a composition of 19% silver, 2.5% copper, 0.018% tin, a trace amount of platinum and the remaining c. 78% being gold (Hartmann 1970, 98 AU1061; Kelly 1983, 101-2; Raftery 1983, 169; Raftery 1991, 560-1). A broad potential date range from 300-50 BCE has been proposed for the hoard of four torcs found at Blair Drummond, Perthshire, consisting of an elaborate loop-terminal torc constructed from and decorated all over with block twisted wire, half of a tubular torc and two twisted ribbon torcs (Figure 4.2; National Museum of Scotland: XFE.109-112, X.2011.6.1, X.2011.6.2, X.2011.6.3, X.2011.6.4; Hunter 2010; 2018, 432). XRF analysis of the surface of all four showed the use of gold alloyed with different quantities of silver and minimal copper. The more elaborate torcs had a higher gold content, up to an average of 77%, compared to the ribbon torcs. Of note here is the composition of ribbon torc XFE.112 (NMS X.2011.6.4), a type specific to Scotland and Ireland, which gave an average surface content similar to the Pulborough torc: 58.5% to 59.4% gold, 37.1% to 38.7% silver and 2.6% to 3.6% copper (Tate 2009; Hunter 2018).

In France, chronological and geographical variation is seen in the composition of pre-Roman gold objects. Relatively high quantities of silver appear in the alloys of 2nd century BCE gold objects, up to 27%, whereas earlier and later objects tend to have higher gold contents and lower silver contents (Armbruster et al. 2021, 429). Armbruster has observed a potential difference in the source of the gold in torcs in France between the 5th and 3rd centuries BCE but notes a lack of analysed examples from the 4th century BCE and the limited number of analyses of first millennium BCE gold objects in Western Europe as a whole. The Pulborough torc, being of stylistically 4th to 3rd century BCE date, potentially lies within the group with limited analyses of contemporary gold alloy artefacts. The gold V-shaped rings, also known as Schaulkelfingerringe, from the late 5th to 3rd century BCE graves in Continental Europe highlight the potential for broad variation in composition within an object type from this period (Waldhauser 1998). The rings are particularly associated with flat grave cemeteries in Austria and Switzerland, including Dürrnberg and Münsingen-Rain (Ulrich 1914; Waldhauser 1998). Examples have occasionally been found in England, although so far none of the latter come from stratified archaeological contexts (Stead 1984, 52 and 62; Cunliffe 2005, 470; Joy 2015, 150). Where the metal content has been analysed the percentage of gold by weight varies from 56.3% to 93.8% for those from burial contexts in Continental Europe (Waldhauser 1998), while the examples from England range from 67% to 89% gold with a silver content from 8% to 29%, the rest being copper (e.g. BM 2011,8016.1 and BM 2018,8003.1, and Shropshire Museum Record 2021.00175).

Comparisons contemporary with the Pulborough torc that have a similar composition are found in the gold alloyed objects from Iberia, namely the filigree ribbons on earrings from the Recouso hoard (Armada and Garcia-Wuelta 2018, 327, table 1). Although the torcs in Iberia have a different form from examples found elsewhere in Europe, it is of note that close comparisons to the simple style and form of the filigree decoration on the Pulborough torc can be found on the hollow sheet metal earrings from the region, such as the navette earring from Santana de Cambas, Beja district, Portugal (Museu Nacional de Arqueologia, Lisbon Inv. No. AU180; Correia 2018, 352). It is tempting to consider the possibility that material and techniques moved along the Atlantic coast at this time, resulting in the distinctive torc type turning up in the southern coastal region of England in a location reachable by boat from the coast. However, this possibility requires further research and more precise compositional analyses of contemporary gold alloyed objects.

The following section describes the design, technical and stylistic features of each component of the torc.

The neck-ring of the torc is made from sheet gold that has been hammered into a tube and joined with a long, slightly meandering, soldered seam running the length of the inside, concave curve of the penannular tube (Figure 5.1). With the aid of a mandrel, a thin curved tool held inside the tube, it would have been possible to hammer the neck-ring to shape from the outside. The soldered seam is visible in a few places along the inner edge of the neck-ring but has split open near the broken end on Part A (Figures 5.2a, 5.2b, 5.2c, 5.2d). Accurate measurements at this point under the digital microscope revealed the sheet to be 0.18-0.22mm thick (Figure 5.3). This part of the seam split through the torsion, which broke and distorted the rest of the object. There is no indication that a separate organic or metal core once filled or supported the tube. Rare examples of cores made from iron or wood have been found in tubular and multi-strand torcs from Snettisham (Meeks et al. 2015; Joy and Farley 2024, 556-7).

The fused buffer terminal torc from the Knock Hoard, Ardnaglug, Co. Roscommon, found in 1861 but incorrectly provenanced to Clonmacnoise, Co. Offaly for a period of its history, bears some similar manufacturing details (Figure 5.4; Megaw 1970, 114, pl. 174; Kelly 1983, 101-2; Raftery 1983, 169, object 452, fig. 143; Raftery 1991, 560; Ireland 1992; Hautenauve 2005, 99). The two tubular sections forming the main part of that neck-ring are each made from a wrought sheet of gold with a soldered and polished seam along the 'concave edge' (Kelly 1983, 101-2). Both tubes on the Knock torc are held at the back of the neck-ring within a hollow expanded component described as a 'box-like feature' (Kelly 1983, 101-2); adorning that box is a 'meandering wire which is soldered to the frame' and provides a close comparison to the filigree ornament on the Pulborough torc described in Section 5.6. Soldered seams to close the hollow torc's body are also found on the late 6th-century torc from Vix, Burgundy, and on the hollow rear part of the late 5th-century Glauberg neck-ring, Germany (Trésor de Vix Musée du Pays Châtillonais; Armbruster 2021, 232; Keltenwelt Am Glauberg; Will 2018).

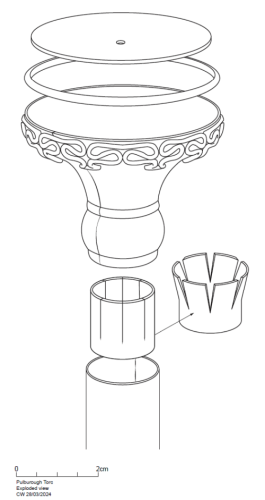

At the base of the terminal and start of the neck-ring there is a plain, bulbous collar demarcated at each end by a narrow band of false beading, maximum 1.1mm thick (Figures 6.1, 6.2, 6.3). The alternating high and low areas are created by indentations made in a raised band. The uneven spacing of the indentations suggests the use of a tool such as a chisel. The reverse side of the terminal sheet on the Pulborough example would have been supported during punching. This tooling creates the effect of a string of beads and is typically described as imitation or false beading but the German term 'Kerbschnüre', notched cord, is perhaps a more precise description (Echt and Thiele 1994 , 95, 99 and 103). Imitation beading on gold objects is well attested from the early La Tène period in Continental Europe from the 6th century BCE onwards (Echt and Thiele 1994). It is used to exemplary effect on the 5th to 4th century BCE elaborate and complex constructed annular gold torcs from Erstfeld, Switzerland (e.g. No. 3 Swiss National Museum A52044 (Kruta 2004, 46-7)). The design of a bulbous collar bound by false beading is familiar from several gold and copper-alloy buffer-terminal torcs created using a variety of different techniques. On the Waldalgesheim torc false beading defines areas of decoration but also acts to hide or distract from the soldered joints between the different cast sections of the terminal and hollow neck-ring (Jacobsthal 1944, 170, no. 43; Guggisberg 2018, 272, fig. 1; Echt and Thiele 1994 , 99-104, fig. 27, locations d and e). It can also be found on the gold torc from Meung-sur-Loire, Les Bruyères, France (BM GR.1867,0508.477), and less sharply rendered on the solid gold Caistor torc from Lincolnshire, England (PAS ID: NLM-605352; Joy 2013), as well as the cast copper-alloy torcs from the River Medway at Aylesford, Kent, England and Somme-Bionne, Champagne-Ardenne (Fox 1958, 66, pl. 26B; BM ML.1430; Stead and Rigby 1999). Like the examples from Continental Europe, on the Pulborough torc each indentation continues beyond the narrow band on either side, and the distance between each punch mark varies round the circumference. In contrast, the false beading on the separate decorative collars on the Sedgeford torc are more evenly and precisely rendered (BM 2005,1103.1 and BM 1968,1004.1; Farley and Joy 2024).

Radiographs of the torc confirm that the terminal and collar are one hollow piece and the neck tube is a separate piece joined to the collar end (Figure 7.1). They also reveal that at the junction of the terminal and the tube, under the collar, there is a separate internal tubular component that is mechanically supporting the join from the inside. This inner tube is cut with a series of short splits forming segments that have been bent outwards slightly to occupy some of the space within the collar and thereby anchor it in place (Figures 7.2 and 7.3). The terminal and the neck-ring have been soldered together above this separate internal component. A smaller scale version of the cut edge of the metal inner tube occurs on one of the rods wedged into the buffer of the torc from Mailly-le-Camp, France, where the border of the rod is described as 'cut into a fringe' (Éluère 1987, 31-3, fig. 21b). Short cuts are also found on the Snettisham Great Torc, where the inner and outer curved metal of the circular ring terminal are joined and the join and solder line are partially hidden by the decoration applied to the surface (Farley and Joy 2024). This is just one solution of many found for supporting and combining the separate elements of Iron Age gold torcs. An alternative complex system is found in the surviving segment of a gold torc, probably from Rheinhessen, where a short copper-alloy tube with three cut-out holes has been inserted as reinforcement into the three-part terminal (Jacobsthal 1944, 171, pl. 61).

The buffer terminal is formed from a gold alloy sheet, of similar composition to the neck-ring, wrought into a trumpet-like shape. The wide end of the trumpet is finished with a convex shoulder giving a rounded shape to the end of the buffer. The sheet is joined with a single, overlapped soldered seam, which is prominent on one side of the terminal (Figures 8.1 and 8.2).

The large, broad, round flared end is of buffer-type rather than the slender, narrowly flared thistle-shape terminals (see e.g. Stead and Rigby 1999, 66-8). The radiographs indicate the terminal sheet may be a little thicker than the tube sheet, with increased X-ray attenuation leading to those areas appearing brighter on the radiographs. A separate disc or plate is also attached across the wide, circular open end of the trumpet (Figure 9.1). It is slightly concave and mostly has the rough texture with dendritic features of a cast surface but with a narrow, polished rim (Figure 9.2). This may be compared, for example, to the internal cast surface of Snettisham torc L.21a from Hoard L (BM 1991,0407.39: Farley and Joy 2024). The use of a cast rather than sheet metal disc as a plate across the open end of this hollow torc may have been designed to add greater strength and integrity at this vulnerable point on the object. There is an intentional small roughly oval, hole in the centre of the disc (1.2mm by 0.8mm), that shows no marks from a rotating drill nor deformation from piercing (Figure 9.2). The hole gives some view into the thickness of the disc, which appears to be thicker than the sheet tube of the neck-ring but a precise measurement was not possible. The lack of tooling evidence and the rough surface of the disc indicate this part was intentionally cast with the hole, probably from a pierced wax disc model that was covered in clay to make the mould for casting.

The combination of several separate hollow components is familiar in gold torc manufacture, exemplified by the Waldalgesheim torc and arm rings, with separate sections cast slightly open using the lost wax technique with a ceramic core and soldered together, including along the inner concave edge (Echt and Thiele 1994, 104-5; Barbara Armbruster pers. comm.; Figure 9.4a). Like the Pulborough torc, a single hole is clearly visible in the centre of each of the slightly concave discs at the end of the cast terminals on the arm rings and formed as part of the wax model (Barbara Armbruster pers.comm; Figure 9.4b). The function of a hole in the disc is primarily the means to ensure heated air can escape from within the otherwise sealed tubular torc assembly when soldering the final terminal in place. If air did not escape, it would be impossible to solder the final terminal to the tube because it would be blown off, or certainly pushed out of position, as the internal trapped air expanded. Such a hole can also be seen on the gold torc from Filottrano tomb 2 (Jacobsthal 1944, 179, no. 44, pl. 38).

The disc plate on the Pulborough torc is slightly smaller than the circumference of terminal end. It is surrounded by a single round section wire that is soldered to the mouth of the buffer sheet and the edge of the disc. This forms the outer perimeter of the terminal and obscures the detail of where the two parts join. Fine parallel striations over some of the bumps on the cast surface of the disc may be the result of minimal attempts to polish away the rough ridges but with limited effect. The disc has a shallow concavity with a distinct flatter, narrow circumferential edge or rim that appears polished to a flat surface (Figures 9.1 and 9.3). By comparison the buffer and thistle-shaped terminals of two of the Leekfrith torcs and the bracelet (STKMG:2018.LH.10.1; STKMG:2018.LH.10.4-5; STKMG:2018.LH.10.3) have concave end discs, this being a design feature for aesthetic and mechanical reasons, and one in particular that bears a strong resemblance to the form of the Pulborough torc despite being solid rather than of hollow construction (STKMG:2018.LH.10.1; PAS ID: WMID-FD08D9.1; Farley 2017). Depressed and concave plates are a common feature of buffer terminals on gold torcs from Continental Europe, including from Czechia, Slovakia, the Netherlands, Italy and Germany, both plain and decorated versions (Echt et al. 2011 , 41). When wearing these torcs the dished ends of the terminals would only be viewable from the side, or at an angle, rather than face on to the end. A fine split or separation (13.6mm long) is just visible on one part of the curved, polished edge of this disc, next to the circumferential wire where it appears to be breaking away from the soldered joint. It is probably a stress corrosion separation, possibly caused by slight deformation pressure that was enough to split this area over time (Figure 9.3).

Filigree decoration ornaments the outside surface of the terminal around the wide trumpet end, and on part of the associated neck-ring for 38mm from just beyond the collar on Fragment A. It is also present at the far end of Part B on the outer curved side, which would have formed the back-centre point of the neck-ring as worn (Figures 1.1, 2.1 and 10.1). The decoration on both fragments consists of lengths of twisted wire attached to the surface of the neck-ring and terminal by means of a coarse solder (Figure 10.2). The wire ranges between 0.4mm and 0.6mm in thickness. Digital microscope and scanning electron microscope imagery show frequent traces along all sections of the wire of the tell-tale diagonal, spiral grooves indicative of hammered, block-twisted wire (Figure 10.3) (Oddy 1977; 1978; Whitfield 1990, 18-20; Ogden 1991; 1999; Cahill 2009, 102-4; Craddock 2009, 377). By skilfully twisting, hammering and rolling a narrow, roughly rectangular, rod of gold, the maker achieved a solid wire with a rounded profile. This preparation of the wire means the diagonal grooves are not visible along its entirety (Craddock 2009, 377). The blade-cut ends of the wire on the Pulborough torc, and some of the open diagonal, spiral grooves along the wire, show it is solid in contrast to the hollow form of strip-twisted wire (Craddock 2009). Both are twisted wire techniques contemporary with one another and characterised, in part, by narrow helical grooves observed on the surface of the wire but the strip-twisted wire is produced from a thin, flattish, strip of metal that is wrapped, rolled and hammered to form a hollow wire (Craddock 2009, 377; Ogden 2023, 150). The term strip-twisted was used in the Treasure Report to describe the twisted wires on the Pulborough torc (Adams 2021) but examination under the microscope proves only solid block twisted wires were used on this object (Figure 10.2). Twisted wire techniques date back to the second millennium BCE and continued in use into the early medieval period until 1000 CE at the latest. This ancient technique was not described until the 1920s and the related term 'strip-twist' only appeared in literature from the 1960s onwards (Ogden 1991). Although interest in and knowledge of ancient wire making techniques began in the 19th century, the method of block-twisting was not described until the late 1930s by Maryon (Craddock 2009, 379) and evidence for copying twisted wire in forgeries dates back to the 1960s, possibly as early as the 1950s (Craddock 2009, 379; contra Machling et al. 2023). In contrast, drawn wire does not appear until after the Roman period in the first millennium CE, continuing in use to the present day, albeit with advancements in machinery for drawing the wires (Craddock 2009, 376). In the 18th and 19th centuries wire was drawn with the aid of powered wire drawers (Ogden 1999, 9), which do not produce the diagonal, spiral grooves characteristic of block-twisted wire observed on the Pulborough torc. There is no evidence for the use of drawn wire on the Pulborough torc, notably an absence of the parallel drawn striations indicative of the technique (Craddock 2009, 376-9). The distinction between drawn and twisted wire is best exemplified in the half-and-half necklace that is in part a remnant of a late 4th to early 3rd century BCE necklace from Greece and part 19th-century restoration by the famous Castellani family of goldsmiths, who specialised in repairing and replicating antique jewellery (Meeks 1998; Craddock 2009, 384, fig. 15.20; BM 1872,0604.651). Despite the production of antique style jewellery in the 19th century, including the fine products of the Castellani family, none of these bear the simple loose sinuous filigree designs of the Pulborough torc nor were they produced with block-twisted wire (contra Machling et al. 2023). Instead, versions of round or beaded wire were used for the filigree work and occasionally two wires twisted together (Ogden 2004, 184).

Solder is particularly noticeable joining all of the decorative wires to the backing sheet, showing characteristic micro-dendritic structures along the joins (Figure 11.1, see also Figure 6.1). Solder is also very apparent on and around the overlapping sheet seam on the terminal (Figure 11.2, see also Figure 8.2). Areas on the sheet between decoration in many places show a texture that is like semi-molten filings of solder that leave a micro-bumpy surface, and in some places, tiny clusters of stray fused solder particles are seen, including near the terminal seam (Figure 11.2). This has a different appearance compared to the 'modern' soldering method of using snipped pieces of strip solder or pallions, which are carefully placed against the components to be joined, and these melt completely and flow instantly at the melting temperature, joining the components without leaving the bumpy texture or stray clumps on the adjacent sheet (Untracht 1975, 159-82; Ogden 2023, 233).

The wire ornament on the outer edge of the neck-ring on Part A, below the collar that separates the terminal from the rest of the torc, is made from seven separate pieces of the rounded wire (Figure 2.1 and Figure 2.2). Four of the pieces form the centre of the design, which is a symmetrical pattern of combined reverse 'S'-shapes and loops. Two angled wires, each with a central external loop, create a loosely triangular design abutting the central component. The final segment is a short section of wire bent into a long loop inserted between the two reverse 'S'-shapes at the collar end of the ornament. To some viewers this image is evocative of a face with eyes and long nose flanked by the draped tresses with out-turned curls.

On the edge of the buffer terminal the wire is formed into a sinuous pattern repeated all around the circumference (Figures 1.1, 2.1 and 2.2). The pattern consists of a simple trefoil motif with one round vertical loop set above two shallower side loops, all repeated nine times running around the edge of the rim and made from one single continuous wire. Though the design creates the impression of symmetry, there is some slight variation in the size and shaping of each loop and a slightly larger gap at the end of the wire between the first and last motif. A further single wire has been attached round the perimeter of the rim of the buffer, disguising the join at the edge of the disc forming the end of the terminal.

On Part B the decorative wire design is incomplete, the remainder having been lost with the rest of the missing part of the torc. The design is different from that on Part A (Figures 1.1, 2.1 and 2.2). One wire is bent into a lyre form with folded ends. Each end abuts another piece of wire, loosely rolled into a circle with the tapered wire end on the inside. At this point the piece is broken. Given the dimensions of the surviving fragments and the difference in the design between the ornament on each piece, this part must be derived from the back of the neck-ring rather than near the missing terminal. The complete torc was adorned at this mid-point as well as at the ends near the terminals. The placement of decoration at the back of the neck-ring is known on some buffer-ended torcs (Éluère 1987, 27), particularly on bronze versions such as those from Champagne-Ardennes, France, including examples in the Morel Collection at the British Museum, for instance the torc from Grave 3, 'Les Closeaux de la Conche', Courtisols, France (BM ML.1711; Jacobsthal 1944, no. 208; Stead and Rigby 1999).

The decoration on buffer and thistle terminal torcs varies between gold alloy and copper-alloy versions but also across these material groupings. Thus, shallow and deeply grooved angular geometric designs, curvilinear patterns, spiral shapes and some high relief human face imagery appear on cast copper-alloy examples while gold alloy examples range from plain to full relief imagery, often with plant and tendril-like motifs or occasionally face-like features (e.g. Jacobsthal 1944, 188-90, pls 125-137; Stead and Rigby 1999, figs 82-86; Kruta 2004, 172-6). The combination of reverse 'S'-shapes and loop motifs on the Pulborough torc is familiar to Waldalgesheim or Vegetal style ornament of the late 4th century BCE, named after the famous torc and intimately linked to Greek and Etruscan designs as found on the situla in the same grave (Jacobsthal 1944, 87-90 and 170, no. 43; Joachim 1995; Guggisberg 2018). The Waldalgesheim style incorporates loops, lyre-shapes, tendrils, and S-scroll motifs in different combinations, more often found rendered in relief on copper-alloy objects, including torcs from graves in the Champagne region, than in wire form (e.g. Bretz-Mahler 1971, pls 598-9; Stead and Rigby 1999). Antecedents of these forms are found rendered in wire, both twisted and beaded versions, on 5th century BCE gold neck-rings, arm-rings, bracelets, and finger rings across central Europe and west into France, with famous examples from the burials at Glauberg, Germany, but also lesser-known fragments like the small hollow neck-ring piece from Dornburg-Wilsenroth (Schönfelder 2003; Hansen 2007). Thus, the rendering of the design in filigree on the Pulborough buffer-terminal torc shows connections both with these 5th century BCE gold objects and the ornate moulded forms and designs of the later 4th century BCE examples. The soldered-on wire decoration is a rarity in objects from Britain and Ireland but is not without comparison. The flared terminals of the gold bracelet found with the Leekfrith torcs is reminiscent of the Pulborough example, albeit in a more expansive and controlled style, combined with chased decoration on the surface below the wires (PAS ID: WMID-FD08D9). The ribbon-like, meander decoration on the intricate joint mechanism at the back of the tubular neck-ring of the Knock gold torc is created from soldered wire (Figure 5.4; Kelly 1983, 101-2). That torc with buffer terminals is described as a French La Tène tubular torc and dated to around 300 BCE owing to its overall design and ornament. A far more elaborate use of filigree is known from one of the gold torcs from Blair Drummond, Stirling, Scotland, that is made almost entirely from curled and furled gold wires (NMS X.2011.6.1; Hunter 2018).

Examples of the sinuous simple ribbon wire soldered to a gold sheet backing are found in Continental Europe. These include a pair of round pendants from the burial of a young woman in the Bettelbühl necropolis on the Heuneburg in Germany dated to c. 520 BCE and thought to be based on objects from the Mediterranean (Beilharz and Krausse 2012, 187). On the latter the wire is laid in a looping pattern running around the central disc, as on the upper part of the curved designs on the Pulborough torc. Other early examples include the flat hoops that hold together the strands of the band of a gold bracelet from the grave of a man in the 'La Cayla du Frouzet' cemetery at Saint-Martin-de-Londres, southern France, each decorated with a simple, sinuous looping filigree design (Dubreucq et al. 2018, 158, fig. 22). This has been dated by associated artefacts to the second half of the 6th century BCE (Hallstatt D3), with the combination of goldworking techniques interpreted as indicative of influences from Iberian, Etruscan, and Atlantic metalworking at that time (Dubreucq et al. 2018). A simple, sinuous, looping line of rounded wire applied to the back of an earring from Madrigalejo, Cáceres province, Spain, is also rendered in the loosely formed style we see on the Pulborough torc; the dating of this piece is less precise and potentially more recent than the other comparisons drawn above being of probable 4th-century date (Correia 2018, 350). In the Lugo province, Spain, more elaborate use of overlapping and tightly spiralled filigree designs show the popularity of and skill in the technique in this region, for example the filigree ornament at the back of the neck ring of the torcs from Burela, Viveiroand Villadonga (Museo Provincial de Lugo; Balseiro Garcia 1994, 138-95, e.g. no. 24 and no. 28; Hautenauve 2005, 205-16). The simple, sinuous, lyre-shaped design from Part B of the Pulborough torc finds comparison in more compact form in the 4th to 3rd century BCE gold wire finger rings as found at Arras, East Riding of Yorkshire (Jope 1995; Megaw et al. 2007, 204-5), and in the Late Iron Age Catillon II hoard from Jersey (Jersey Heritage record: STATES/CATII/F/00061). The former, illustrated but now missing, and the latter, found squashed, show the use of similar ornamental wire forms on open objects where the skin of the wearer formed the backing to the design rather than sheet metal and may be compared with contemporary rings from western and central Europe (e.g. Megaw et al. 2007; Waldhauser 1998). The style of ornament found on the Pulborough torc, therefore, has counterparts dating from the Iron Age in Continental Europe and closer. The wider use of filigree decoration on torcs is associated with two phases in the Iron Age, being present on Hallstatt D3 finds c. 500-450 BCE and again in La Tène D1 c. 150-50 BCE on the large tubular torcs with wheel-shaped buffers, such as that from Mailly-le-Camp, Aube, France (Éluère 1987, 33, fig. 21b; Joffroy 1969). However, 3rd century BCE finds like the Knock torc from Ireland indicate there are exceptions to this rule or, at least, scope for a review of the dating taking new finds into consideration.

This broken hollow torc shows features typical of a gold alloy object that has been buried for many centuries. The general condition of the torc is good, apart from the obvious breaks and the part-straightening of the tubular part 'B'. The surface has numerous age-related pitting features common to buried gold alloys, particularly those containing high silver, plus numerous random and different-sized scratches both superficial and deep that are consistent with age and use (e.g. Figures 5.2, 6.2, 14.1). There are various small indentations and striations visible on both the wires and the other surfaces of the torc. These pertain to the processes of making and shaping and polishing; to subsequent wear and tear; and some to possible damage prior to or during discovery. There are clear indications of newer, more severe, damage scrapes that are consistent with the recent discovery and extraction from the ground or farming activity (Figure 16.2). These scrapes have bright, clean, and shiny surfaces. Small, faint scratches on the tube and wires are consistent with recent cleaning after recovery from the ground.

Use-wear is clearly visible, particularly on the prominent wire decoration on the neck-ring and terminal, which was more vulnerable to daily wear against clothing or the body by dint of being higher than the surrounding sheetwork. The filigree decoration at the back of the neck-ring parts still stands round and proud of the sheet to which it is attached but that around the edge of the terminal is far flatter and smoothed where the torc would rest on the wearer's clothing. The decorative wire is worn almost flat on the edge of the widest part of the terminal, which is the most exposed region (Figure 12.1). This damage is particularly visible under the digital microscope and scanning electron microscope (Figure 12.2). A difference is even noticeable between the loop parts of the wire on the sloped surface of the terminal and those located around the widest curved edge of the terminal. This area would wear preferentially because it is constantly either resting on the wearer's clothing when in use or on any surface when it is taken off and put down. This edge is particularly worn on one side (the side facing the viewer on Figure 3.1) suggesting the possible orientation of the torc when worn, that side being the lower edge resting against the body or clothing of the wearer.

The two torc fragments, when put together, comprise half of an original torc that appears to have been broken at the midway point of the neck-ring. The two extant fragments are also broken in two. The condition of the two fractures is different, suggesting these breakages took place at different times. The hollow terminal with its wire decoration is neither damaged nor deformed by the breaking processes.

The tube fracture at the decorated region of Part B, which adjoined the missing part of the torc, is rounded and not metallurgically granular compared with the break that has separated Part A and Part B (Figures 13.1a, 13.1b, 13.1c, 13.1d compared to Figure 14.3). The condition suggests this is an old break that occurred potentially before the torc was buried. It is possible that this first separation is an ancient cut to render two pieces for burial. The torc tube has not been simply squashed, ripped apart or destroyed and appears to have been more of a deliberate division than destruction. The lack of bending or splitting of the seam next to this break can be contrasted with the damage seen around the second break, described below. The deposition of deliberately broken and fragmented metal objects and curation of parts of objects before burial has a long history in north-western Europe (e.g. Fontijn 2020). Although archaeologically these practices appear to be less ubiquitous post 750 BCE than for the preceding 500 years, they do not disappear, as attested by the deposition of incomplete and broken and repaired torcs in the Snettisham hoards and single fragments such as the Caistor torc (Figure 3.2; Stead 1991; Joy 2013; La Niece et al. 2018; Farley and Joy 2024). Thus, the Pulborough torc may be added to an ever-growing catalogue of artefacts that fuel debate about the intentions behind processes and practices of deliberate breaking, retention, curation, and burial of well-crafted objects from about 450 BCE to 50 CE, the 'second Iron Age' in European discourse (e.g. Joy 2010; Giles 2012; Chapman 2018; Chittock 2019).

The break between Part A and Part B is a secondary break, which has the typical cracking and metal separation associated with stress corrosion or fatigue breakage and characteristic deformation of part of the tube at the final point of breakage (Figures 14.1 and 14.2) (Dugmore and DesForges 1979). The transverse crack is straight across the tube on the outer convex curved surface down to over halfway through the diameter of the tube (Figure 14.1). This suggests that the tube had largely corroded through at this point over time and when separation occurred there was no deformation of the tube here. Flexing of the torc when putting it on and taking it off during use could have initiated the fatigue crack that subsequently corroded further during burial. By contrast, on the inner, concave, surface at the break there is much fine cracking on the gold surface associated with the final deformation of this part of the tube wall at failure. This has left a pointed tear caused by the last bending, showing the metal was still connected in this area before breakage (Figure 14.2). There is also a long split along the tubular seam on Part A and a deformation kink pointing outwards along this broken edge on the concave side of the neck-ring, from bending during breakage (Figure 14.3). This is the point of final fracture. The digital microscope images reveal the fine lines from the original polishing of the torc during manufacture with lines clearly continuing either side of the break (Figure 14.1). These longitudinal striations are bisected by later diagonal lines cutting across the top of the polished surface, probably inflicted through use and wear. These in turn are distorted where the torsion has caused the seam to split and separate as it broke. There is no sign of a blow to the torc at this point of final breakage but the largest blow, leaving the deep scrape, is on the tube Part B (Figure 16.2).

It is possible the damaging blow was inflicted by agricultural activity while the torc was buried in the ground, or during discovery. It is possible that this blow, and the associated dragging movement that occurred, separated the remaining tube into two pieces. This has also distorted the curve of the neck-ring, almost straightening a section of the tube on Part A and deforming it slightly laterally, creating a twisted effect (Figure 3.1).

The gold has the appearance of having been superficially cleaned after it was dug up to remove most, but fortunately not all, of the adhering clay-rich reddish-brown soil, which is visibly trapped in the split and around the decorative wire designs (Figures 15.1 and 15.2). Also, the soil from within the tube has been removed, which has resulted in new scratch marks inside where the soil had been scraped or pulled from within (Figure 15.3). The cleaning process and other post-find activities resulted in numerous fresh surface scratches, although surface deposits of a red-brown organic material adhering to the neck-ring across the underlying ancient scratches and surface texture on the gold show that post-excavation cleaning has not been overly vigorous in these areas (Figure 15.4).

There are some deep modern scrapes and damage on the wire of both parts (Figure 16.1) and a particularly deep scrape and indentation on the side of tube Part B (Figure 16.2). This severe long fresh scrape and associated indentation is clearly from either a farm implement or the initial tool that may have struck the torc during finding and/or removal from the soil. The scrape has exposed fresh sub-surface metal and left parallel transverse 'chatter' marks on it and the associated indentation in the tube (Figure 16.2). The direction of the strike is from the undecorated side and dented the tube inwards. This blow may also have resulted in final separation of the two parts of the discovered torc. Similarly, there are two severe deep scrapes across the wire decoration, one on Part A by the terminal end (Figure 16.1), and the other on Part B (Figure 15.2). These too are recent and most likely from tools used in the primary discovery and/or extraction from the ground. This type of farm machinery damage causing separation breakage has been seen on, for example, the Sedgeford torc, where one terminal was torn from the neck-ring (BM 2005,1103.1 and BM 1968,1004.1; Brailsford 1971).

The metalworking techniques used to make the Pulborough torc are all consistent with ancient goldworking: sheet metal, block-twist wire, seam work along the tubular sections, punched decoration, cast end disc with central hole and soldering. The condition of the gold surface is consistent with it having been buried for a long time, being pitted and with cracking of the gold alloy and patinated wear-scratches. The exposed surfaces of the torc have much use-wear consistent with the torc having been worn for some considerable time. The primary break with the missing torc section is consistent with the hypothesis of the torc having been deliberately broken in half, rendering the object unusable but not destroying it. By contrast, the break between the two remaining pieces shows metallurgical evidence of stress corrosion cracking that weakened the tube while buried, causing a crack to half the diameter of the tube (Dugmore and DesForges 1979). It was finally broken by a recent blow with a metal implement (either from farming activity or discovery) that distorted the other half of the tube and tore and deformed the remaining metal at the break point.

Technical and stylistic features of the find may be compared with known Iron Age examples of torcs and other gold work from across Europe, specifically France, Germany, and Iberia as well as rare examples in England, Scotland and Ireland (Hautenauve 2005). These features occur on objects across a broad period from as early as the 6th century BCE to as late as the 1st century BCE. While it is not possible to be confident about the precise date of this find without an archaeological context, the present authors propose the same date range assigned to the gold buffer terminal torcs of the Meung-Loire region, France: the 4th to early 3rd century BCE c. 400-250 BCE (Nordez et al. 2019). Like these French finds, the date range may be more precisely c. 375-275 BCE but it is not yet possible to be so specific for the Pulborough torc. Although there are no direct parallels for this torc there is nothing to suggest anything other than it being another interesting ancient torc of a similar design to some European types, using traditional techniques but with some innovative flair on the goldsmith's part with the wire decoration. That innovation may be compared with the individual designs of torcs from Britain and Ireland, including the Knock and Blair Drummond torcs. There is no evidence that this might be a modern forgery (contra Machling et al. 2023).

The overall construction of the design of the Pulborough torc may not have the impressive high-quality decoration of some of the exemplary examples of Iron Age gold torcs from Snettisham like the 'Great Torc' (BM 1951,0402.2, Hoard E; Stead 1991) but it is a skilfully crafted piece. There is considerable variation in the way each gold and gold alloy torc is constructed, particularly among the buffer terminal types. Although most have the external appearance of being made as a single piece, they are all composed of several components, some cast and some wrought and joined together by means of soldering and hidden joints. The block-twisted filigree finds comparisons across western Europe from the first millennium BCE from Ireland to north-west Spain. The buffer-terminal shape, features of the ornament and construction all place this comfortably within the second half of that period, in the 4th to 3rd century BCE. Pulborough can be added to a small but growing group of mid- to late first millennium BCE gold items of personal adornment found in England. These finds may have been created locally using imported techniques and metal or by a non-local artisan, but it is possible this torc was a direct import from across the channel or along the Atlantic coast. This period is marked by a 'significant increase in the range and quantity of non-ferrous metalwork' in Britain and Ireland, and visible Continental connections in the style of ornament on more highly decorated items (Webley et al. 2020, 138). This incomplete torc adds another piece to the assembling story of long-distance connections and local variation in the 4th and 3rd centuries BCE being revealed through artefact study, settlement research and landscape investigation across Europe (see e.g. Joy 2015; Webley 2015). It acts as a pertinent reminder of the incomplete nature of the record and the growing frequency of new and unexpected finds to enrich this dataset.

The Pulborough torc is an important addition to the corpus of Iron Age torcs from Europe. This investigation exemplifies the value of careful scientific examination under the microscope, the need to understand the holistic approach to the metallurgical evidence that the object displays and the importance of comparative material when investigating new and unexpected finds. This study has showcased the current techniques that can help reveal the full object itinerary of such finds (after Joyce and Gillespie 2015), from crafting to wearing, damage to deposition, recovery and cleaning to analysis. It highlights the value of combining fine-grained scientific analysis with typological and stylistic studies, and knowledge of local and international finds. The scientific techniques employed and high-powered microscope imagery reveal the distinctive characteristics of ancient construction methods and age-related gold surface textures, along with clear evidence of recent damage and rough cleaning that the object has been subjected to since discovery, which leaves its own 'fingerprint'. Here we have illustrated the complex and detailed interrogations that may be undertaken to identify and qualify precious metal objects where the archaeological context is limited or lacking. Most importantly, this study is the outcome of careful, detailed, methodical and collaborative, interdisciplinary research made possible by the acquisition and accession of the artefact into a museum collection.

We extend our sincere thanks to everyone who has contributed their time, knowledge, skills, and experience to examining this artefact, especially Jack Ogden, Judy Rudoe and Barbara Armbruster. Thank you to Emma O'Connor at The Barbican Museum, and the Trustees of The Sussex Archaeological Society for enabling this research and to Jill Cook, Rebecca Stacey and Aude Mongiatti at The British Museum for their support. Our thanks also to the finder for diligently reporting their discovery to the Finds Liaison Officer. We are very grateful to Tony Simpson, David Ager and Craig Williams at The British Museum for their professional, high-quality imaging, illustration and photography, and to Pippa Pearce, Rachel Weatherall and Rachel Berridge for conservation advice and metalwork knowledge. We are also very appreciative of the support we have received from colleagues at the National Museum of Ireland and National Museum of Scotland as we have undertaken this research, especially Maeve Sikora and Fraser Hunter. This research was made possible thanks to the generosity and collaboration of all the authors. The article has been enhanced by the invaluable comments from peer review and the diligence of the journal editor, Judith Winters.

Internet Archaeology is an open access journal based in the Department of Archaeology, University of York. Except where otherwise noted, content from this work may be used under the terms of the Creative Commons Attribution 3.0 (CC BY) Unported licence, which permits unrestricted use, distribution, and reproduction in any medium, provided that attribution to the author(s), the title of the work, the Internet Archaeology journal and the relevant URL/DOI are given.

Terms and Conditions | Legal Statements | Privacy Policy | Cookies Policy | Citing Internet Archaeology

Internet Archaeology content is preserved for the long term with the Archaeology Data Service. Help sustain and support open access publication by donating to our Open Access Archaeology Fund.