Figure 6: Consumption rates of raw material at Huizui based on tool types

The first stage in a stone tool production-distribution system is raw material procurement. A wide range of raw materials can be found in close proximity to Huizui, especially within the Song Mountains (Figure 7), indicating a strong possibility for there to be significant evidence of choices made regarding raw material selection. To investigate these choices, raw material selection was examined from three perspectives: raw material specialisation, proximity of source and the properties of raw material sources.

Raw material specialisation was examined through the frequency, or consumption rates, of the different raw materials used to produce the different tool types. Specialisation of resources reduces the time and costs involved in procuring raw materials, thus contributing to the overall efficiency of the system (Torrence 1986, 44; Blanton 1985, 122). The benefits of focusing upon a particular raw material include allowing for standardised production techniques, less time and energy spent visiting and extracting different raw materials, and an increased level of skill acquired from working with a particular raw material, which can decrease error rates and time taken to produce a tool (Torrence 1986, 44).

Raw material specialisation can also be considered as evidence for standardisation of the product, which is associated with stone tools produced for regional exchange (Ericson 1984, 6; Torrence 1986, 44). This is due to the stone tool producers making tools for an export market, where the lack of a direct relationship between consumers and producers (Arnold 1985, 38) mean that tools are made to a market ideal rather than a personal order. Conversely, tools that are made for local consumption may therefore show variation in their raw material types as a direct relationship with the producers means that they are more able to influence the overall design process.

At Huizui, each of the six tool types was shown to be associated with a particular raw material, with spades produced from oolitic dolomite; axes, adzes and chisels from diabase; knives from micaceous sandstone and grinding slabs from various sandstones (see Figure 6). This indicates that raw materials were specialised according to tool type. Raw material is also linked with broader functional groups. For example, woodworking tools are primarily made from diabase, while cutting tools are made from micaceous sandstone. The only tools that are made from a variety of raw materials are the grinding slabs. However, as can be seen from Figure 6, this variety is of different types of sandstone, rather than completely different raw material types. There appears, therefore, to be a correlation between raw material type and function of tool, suggesting that choice of raw material may be at least partly due to its functional properties. This is a common occurrence in most stone tool using societies, especially where there is a great diversity of raw material available (Ericson 1984, 6).

Raw material procurement was analysed by determining the proximity of raw material sources to Huizui. The assumption in analysing distance to source is that it is more efficient to utilise local raw material sources. Costs incurred from using non-local sources include increased time and energy required in transport (Earle and Ericson 1977, 6; Ericson 1982, 131; Renfrew 1977b, 72; Sidrys 1977, 98), especially as lithic material is very heavy and transport methods during the Erlitou period may have been primarily human based. Distant quarry sources may also have required the creation and maintenance of social relationships with the owners of the quarry area to gain access (Blanton 1985, 116; Bradley and Edmonds 1993, 7; Earle and Ericson 1977, 8). As we have already seen that raw materials were specialised according to tool type, if these were to be efficient and economic choices, it would be expected that they would be located close to Huizui. This is especially the case if tools were produced for export as it is more economical to access large quantities of raw material locally than to acquire raw material from a distant source (Ericson 1984, 6; Earle and Ericson 1977, 6).

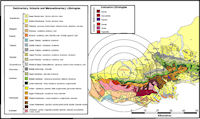

A geological survey was completed of part of the Song Mountains where traverses of the mountain range were walked to identify possible lithic sources (Gorton 2003). This was conducted in two seasons, the first by Dr Guowei Xu and Justin Gorton of the Earth Sciences Department at La Trobe University, and the second by Dr John Webb, also of the Earth Sciences Department. Using these traverses and previous geological surveys, a map was created outlining all the available raw materials within the Song Mountains (Fig. 7).

Figure 7: Distance of raw material sources from Huizui (based on Gorton 2003)

To establish what raw material sources were utilised, thin-section analysis was completed of a sample of tool blanks from Huizui, and compared to samples taken from nearby sources of feldspathic sandston, violet sandstone and oolitic dolomite. The results of this analysis showed that the two sandstone outcrops located within one kilometre of Huizui were the sources for the feldspathic sandstone and the violet sandstone, and the oolitic dolomite originated from Cambrian outcrops in the Song Mountains, within five kilometres of Huizui. For the remaining raw materials, it was determined that the most likely source used would be the closest. In future, this assumption requires testing through the use of geological sourcing techniques such as thin-section or chemical analyses.

The proximity of raw material sources to Huizui is shown in Table 2. This shows that five of the six major raw material types are found within ten kilometres of Huizui. This includes feldspathic sandstone, sandstone, violet sandstone, micaceous sandstone and oolitic dolomite, which altogether consist of 92% of the targeted assemblage. This result would appear consistent with the hypothesis that dominant raw materials were located within close proximity of the stone tool production site to maximise efficiency. The location of the two sandstone outcrops within one kilometre of Huizui is especially significant for a site specialising in ground stone tool production, as sources were used to produce grinding slabs for the manufacture of the tools.

The remaining dominant raw material type, diabase, is more difficult to classify regarding distance from Huizui. Figure 7 shows that diabase is present within 30 kilometres of Huizui. However, most of the diabase tool blanks present at Huizui are made from waterworn cobbles. These cobbles are most likely to have been transported from the diabase source in the Song Mountains via rivers, from which they were taken to be used at Huizui. It is therefore possible that diabase cobbles may have been available within gravel beds in close proximity to Huizui. Further survey of river beds flowing from near the diabase source is required to investigate this proposal.

For the less dominant raw material types, only chert and the different types of limestone are found within five kilometres of Huizui (Table 2). Other raw materials are found between 15 to 20 kilometres away, or even possibly further in the case of aplite, gabbro and gabbro gneiss, which did not have identifiable sources within the region. While it was considered possible that cobbles of these raw materials would be located closer to Huizui, as in the case of diabase above, an analysis of the tool blanks of these raw materials showed that their original form was mostly indeterminate, making this hypothesis inconclusive. Two of the siltstone tool blanks were in slab form, suggesting that they were quarried at source rather than picked up as waterworn cobbles.

The low consumption rates of the less dominant raw materials, and their relative distance from Huizui in relation to the dominant raw material types, may indicate several different scenarios for their use at Huizui. This is largely dependent upon what form the tools were brought into Huizui, that is, whether they were imported as raw materials, tool blanks or finished tools. Most of the less dominant raw materials are found as finished tools (75%), with only a marble axe, aplite knife and gabbro knife found as tool blanks. Therefore it would appear likely that these tools were produced off-site, either at the quarry source or another production site, before being imported into Huizui for use. The reasons for their importation could be multiple and may include targeting these raw material types based on perceptions of quality or value or the creation of social relationships through exchange or gift giving (Edmonds 1995). However, it is also possible that these tools were produced at Huizui, but in such small numbers that recovery of evidence of their production is difficult. Currently, there are no areas of manufacture at Huizui that appear to produce tools made from the less dominant raw materials. If these tools were produced at Huizui, this may also be for several reasons, including experimentation with raw materials or the opportunistic embedded procurement of these raw materials during trips made primarily for other purposes. Because of the multiple explanations available to explain the presence of these tools at Huizui, further analysis is required of where the less dominant raw materials came from and their location of production before more conclusive answers can be given.

A review of raw material properties is provided in detail in Webb et al. (2007) and will not be repeated here. However, it appears that functional and extractive properties may have contributed to raw material selection. Raw materials such as diabase, oolitic dolomite and micaceous sandstone may have been selected based on the similarity of size and shape of the original form of the raw material to the finished tool. For example, oolitic dolomite, unlike other limestone, exists in cliff formations, overlaid by a soft siltstone (Webb et al. 2007). This siltstone is easily weathered, thus leaving the beds of oolitic dolomite open for extraction, which can then be broken off into large slabs. The thicknesses of the slabs are controlled through the presence of natural fracture planes. These natural fracture planes have a red-coloured ferruginous staining, which is also visible on many of the oolitic dolomite tool blanks. The presence of the staining on both sides of these tool blanks shows that the quarriers were making use of these natural fracture planes to control the desired thickness of the tool blank and also to enable quicker and easier quarrying. The use of oolitic dolomite therefore not only reflects an efficient choice of raw material based on quarrying properties, it also demonstrates that the stone tool producers were selecting tool blanks that were close to the desired thickness of the finished tools, thus minimising the time and effort required to reduce the tool blank and increasing the efficiency in the overall production of the stone tool.

Functional properties may also have been a factor in the choice of raw material. As described above, particular raw materials were utilised for the production of different tool types. In some cases, raw materials were also selected for broader functional classes, such as diabase for woodworking tools and sandstone for grinding tools. This would indicate that particular functional properties were sought after, depending on the use of the tool.

The choice of raw materials used at Huizui would appear to be a reflection of proximity to source, quarrying and functional properties. The combination of all of these properties suggests that the stone tool producers at Huizui were making cost-efficient decisions on raw material selection, based on more than one criterion, for all six tool types. In order to pursue this hypothesis further, more sourcing analysis is required to identify accurately all raw materials used at Huizui with their source. Further research is also required to quantify the functional and quarrying differences between the raw materials, examining factors such as the difficulty of extraction of the raw material, time and effort required to manufacture it, and longevity and capability of tools produced from the raw materials. Through examining all of these factors in more detail, a more definite view of the most efficient raw material choices can be gained.

© Internet Archaeology/Author(s) URL: http://intarch.ac.uk/journal/issue26/15/6.html

Last updated: Wed Jul 1 2009