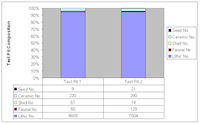

Figure 10: Assemblage composition within stone tool production contexts

The organisation of production at a site is a complex issue and thus several different aspects, most of which are interrelated, can be investigated. One of the most common ways of investigating how production is organised is to examine the spatial distribution of activities at a production site. This involves identifying what activities occurred on site, where they were located and how these areas were related. This information can then be used to explore questions such as the range of activities that occurred on site (Bradley and Edmonds 1993, 98-100), whether there is any evidence for technical division of labour (Nassaney 1996; Cleghorn 1985; Ericson 1984; Rands and Bishop 1980), and whether production was organised within a household or workshop context or associated with elite control (Torrence 1984, 60; 1986, 49; Spence et al. 1984, 98; Spence 1981, 771-2; Arnold 1985, 44; Shafer and Hester 1983; Costin 2001, 276; Santley and Kneebone 1993, 41).

In the preceding discussion, spatial specialisation was preliminarily reviewed by examining whether there was any evidence for different manufacturing stages being completed at different sites. This type of spatial specialisation is on an inter-site or regional level. The following discussion will now focus on the intra-site spatial organisation of activities at Huizui by investigating whether there is any evidence for either the specialisation of space or labour in the stone tool production area. Specialisation of space is considered efficient as it allows the entire production process to be confined to one area (Torrence 1986, 44; Arnold 1985, 37). This should allow for concentration on stone tool production, with a minimum of intrusion from other activities. Arnold (1985, 44) also indicates that specialised use of space for stone tool production allows the craftsmen to pick the ideal location for this activity, which should have easy access to raw materials, be comfortable for production and avoid living areas. All of these factors should allow the stone tool craftsmen to produce tools more efficiently than if stone tool production was embedded with other activities. Evidence for spatial specialisation at Huizui therefore should include separation of stone tool production from other activities and may also involve segregation of activities within the stone tool production area itself.

Specialisation of labour is also considered efficient as it allows the skill levels of the stone tool craftsmen to increase as a result of repetition of particular manufacturing techniques (Torrence 1986, 44; Santley and Kneebone 1993, 41; Wattenmaker 1994, 113). An increase in skill is considered efficient for several reasons, including less time required to produce stone tools (Perles 1992, 134), lower error rates (Costin 1991, 40; 2001, 282) and the ability to conserve raw material, thus reducing time and costs in raw material procurement. Evidence for specialisation of labour at Huizui will be based on the evidence for spatial specialisation and can occur on two levels. The first is the separation of stone tool production from other activities, which would suggest that production was completed by particular craftsmen rather than everyone in the community. At a finer level of detail, segregation of activities within the stone tool production area may also indicate that different craftsmen specialised in particular manufacturing techniques.

Context of production will also be discussed by examining the level of integration of stone tool production within the local subsistence economy. Context of production is usually divided into typological categories, which rank different types of production units. These production units are usually distinguished by scale, intensity, control and concentration or spatial setting (Costin 1991; 2001; Santley and Kneebone 1993; Smith 1994; Arnold 1985). Context of production is also linked with purpose of production, with different levels of production units associated with different levels of distribution (Costin 1991, 11; Santley and Kneebone 1993, 39; Spence 1981), although this link is generally assumed rather than proven. While there are a range of different typologies of production units used (see Costin 1991 and 2001 for a review), the current study will use the two general terms that are most commonly referred to in the archaeological literature. These are household and workshop production.

Household production and workshop production are usually distinguished from each other based on scale, intensity, control, purpose and spatial setting of production. Households are domestic units that are usually related by kinship (Santley and Hirth 1993, 3; Hirth 1993, 22). Household production is considered to be aimed at providing for the needs of the household; therefore production should be small in scale, part-time in intensity, controlled by the household, free of external influences, and situated in or within close proximity to the household area (Smith 1994, 150; Santley and Kneebone 1993, 38-9; Underhill 2002, 286). Workshops, on the other hand, are considered to be specialised activity areas utilised by craft specialists that produce surplus goods for exchange (Arnold 1985, 44). Workshop production should therefore be characterised by specially delineated activity areas, free from household debris and separate from living areas (Arnold 1985, 44; Underhill 2002, 286; Santley and Kneebone 1993, 41). Workshops should also be of a large scale, with either full-time or at least part-time craft specialisation, and may be influenced by external controls. An important implication for the current study is that workshops are considered to be more efficient in production than households. The presence of workshops may therefore suggest that stone tool production was a special purpose activity, considered separate from other household daily activities and that stone tools produced in workshops differed in their distribution from tools produced in households.

As discussed above, the two 1x1 metre test pits were excavated during the 2002 field season depicted two very different types of manufacturing areas. Test Pit 1 is a stone tool production area, complete with structural remains. Test Pit 2 is a refuse dump that may have lain outside a wall, although it is unclear whether this was a fence or a structure. As both of these test pits demonstrate clearly that stone tool manufacture was being conducted in this area, the next step in analysing the context of production is to determine whether these areas were part of household or workshop production units. This will be completed by comparing the level of household debris within the two test pits to the levels of manufacturing debris.

Figure 10 shows the different types of materials present within the stone tool production contexts for each test pit. The identification and number of stone, faunal and ceramic remains were recorded by the author. Seed remains, however, were recorded by Sheahan Bestel in her study on the archaeobotanical remains from Huizui West (Bestel 2006) which identified all of the cultivated plant remains. As Bestel recorded all of the samples in Test Pit 2, rather than the half studied for the stone tool analysis, I have halved the number of seeds Bestel identified for this comparative analysis. In total, for Test Pit 2 Bestel identified 41 foxtail millet seeds and one soybean seed. Other plant remains were also present but these were weedy and herbal taxa that were probably utilised by humans.

Two patterns are visible in Figure 10. The first is the overall similarity of the assemblage composition of the two test pits. Although these test pits differ remarkably in their structural composition, there is a distinct similarity in the range and amounts of the different artefact classes. This would suggest that similar activities were occurring at the same level in both places.

The second pattern is the sheer dominance of stone manufacturing debris present within the two assemblages. While there are small amounts of ceramic, faunal and shell remains, these are minor compared to the very large amounts of lithic material. This would suggest that within the stone tool production context of each test pit, stone tool manufacture was the dominant activity. Other household activities may also have occurred within the area, but not to the same extent as stone tool production.

Because of the dominance of manufacturing debris, I would first propose that the two test pits excavated in Huizui West were specialist stone tool production areas. Whether or not these areas belonged to households or workshops, however, is difficult to determine. From the definitions above, it should be possible to distinguish a household or workshop within the archaeological record based on the level of household debris associated with stone tool production debris. From Figure 10, it can be seen that domestic activities did occur within the stone tool production contexts. The smaller number of domestic artefacts associated with these activities may indicate a number of situations. The smaller numbers may suggest that domestic activities did occur within the stone tool production area but that stone tool production was the main focus. They may also represent the different accumulation rates of different types of archaeological material. That is, the manufacturing debris from stone tool production may accumulate at a faster rate than domestic remains based on the large amount of waste generated during the production of each stone tool (as shown by Owen's 2006 experiments – see above).

Household production would therefore appear to be the most likely type of production at Huizui West, which is supported by other assessments of the area, including Bestel (2006, 97) and Liu et al. (2007). This is based on several factors. The first is the association of household debris, although in small amounts, with the stone tool production contexts within the two test pits. The second factor is the range of other archaeological features excavated by the Yiluo River Valley Archaeological Project within the stone tool production area. In 2004, the project excavated 100 m² within the stone tool production area. From this excavation, they recorded 28 ash pits, two burials, a house, a water well, an ash ditch and a path or road. All of these features date to between Erlitou I to Erlitou III, although most date to Erlitou phases II and III. The house is particularly interesting as this is located within five metres of an ash pit that contained a large number of stone flakes and tool blanks, similar to that seen in Test Pit 2. The presence of these other features within the stone tool production area would therefore indicate that stone tool production occurred within a domestic setting, which is indicative of household production.

Now that it is established that particular areas were dedicated to stone tool production within Huizui, the next step is to determine whether there is any evidence for spatial specialisation of activities within the overall production area. As can be seen from the above analysis, the production of oolitic dolomite spades is of obvious importance, with very little evidence for other stone tool production found within either of the test pits. This suggests that there may at least be spatial specialisation with regard to the production of tool types or particular raw materials. The following discussion will therefore review what types of spatial specialisation may be expected, before using the shovel test data gained in 2002 (See Figure 2) to examine whether there is evidence for any of these activities on site at Huizui.

To begin with, ground stone technology involves a number of steps in production (see Ford 2001; 2004 for a detailed discussion on production strategies utilised at Huizui). This means that craftsmen may have specialised in particular manufacturing techniques such as the initial roughing out of the blank or the final polishing stage. If the craftsmen did focus upon particular manufacturing techniques, then areas showing different manufacturing debris attributable to that technique would be expected. For example, if a craftsman specialises in grinding or polishing, then partially ground or polished tool blanks and grinding slabs would be expected, with little or no flaking debris present. However, if all stages of manufacture were present, then it would suggest that each craftsman completed the entire manufacture of the stone tool.

Craftsmen may also have specialised in the particular stone tools that they produced. As there is a direct link between raw material and stone tool type, it would be expected that if particular craftsmen specialised in producing a particular stone tool, only the raw material associated with that stone tool type would be located in his or her working area. For example, if a craftsman specialised in producing woodworking tools, then only diabase and the sandstone grinding slabs used in their production would be expected in their working area. Apart from raw material, the tool blanks and finished tools present within a working area can also show what types of tools were produced there. However, as very few tool blanks and finished tools were recovered from the shovel tests, they may not provide significant information regarding spatial distribution of activities. By exploring the spatial distribution of raw materials, manufacturing debris can also be used, which may be a more effective measure than focusing upon tool blanks and finished tools.

Three types of spatial distribution of activities are therefore possible within the stone tool production area: raw material use, type of tool produced and production technique utilised, although raw material use and tool type are linked. The shovel test data will now be investigated to identify if different patterns of tools and techniques are present within the stone tool production area and to identify what type or if spatial distribution of activities occurred at Huizui.

Four particular types of raw material; oolitic dolomite, diabase, sandstone and micaceous sandstone, were selected as they are the raw materials used to produce the most abundant tool types on site. Oolitic dolomite is the most widespread and abundant raw material on site, which reflects the dominant production of spades at Huizui (Table 5). Oolitic dolomite was found in 39 locations, although in varying densities. Sandstone is also widespread, being found in a total of 21 shovel tests, although not in numerous amounts. As sandstone is used in ground stone tool production, the presence of sandstone in various parts of the site could identify areas where the grinding of stone tools took place.

Diabase and micaceous sandstone were both found in very small amounts, in localised areas within the stone tool production area. What is apparent from examining the raw material distribution is that the different raw materials were all located within the same areas. Rows 2, 4, 6 and 8 of shovel tests included all materials, suggesting that all types of stone tools were manufactured in these areas. The spatial patterning of every second row indicating a centre of production is interesting, as it shows that the multipurpose production loci were evenly spaced within the overall production area. The recovery of sandstone from all the production loci may also indicate that grinding occurred in all these locations.

Rows 1 and 12 showed a combination of oolitic dolomite and micaceous sandstone, and Shovel Test 17 showed a combination of oolitic dolomite and diabase. It is possible, therefore, that these areas show a spatial distribution of activities, with Rows 1 and 12 concentrating on spade and knife production, and Shovel Test 17 concentrating on spade and woodworking tool production. However, the small amounts of material located in these areas means that this spatial distribution is not conclusive. In all, the analysis of raw material use shows that different raw materials are utilised in the same areas, indicating that particular production loci existed but with no division between raw materials.

The results of the spatial distribution of tool types were very similar to that of the raw material distribution but in less detail. Oolitic dolomite spades were the tool type most widely manufactured on site. All of the spades located by the shovel tests were tool blanks, indicating that they were manufactured in these areas, rather than finished tools that may have been discarded during use. As the spade was a mass-produced tool with the highest production volume on site, the widespread nature of its manufacture is to be expected.

Grinding slabs are also widely spread throughout the stone tool production area, but mostly in those areas identified above as possible production loci. The existence of grinding slabs used to manufacture stone tools in these areas strengthens the proposition that these particular areas were production loci, especially in Row 6, which had the highest amount of grinding slabs and also a hammerstone, indicating that this area most certainly was used to produce stone tools. Row 6 is of particular interest in that it also contained an adze/axe tool blank and two knives; one finished and one tool blank, as well as oolitic dolomite flakes, showing that it was an area used to produce a wide range of different tool types.

The third type of possible spatial distribution identified was the specialisation of manufacturing techniques. Ground stone tools undergo a variety of processes before the finished tool is ready (Ford 2001; 2004). Evidence for specific areas allocated to these production techniques may indicate a specialisation in labour or skills by the stone craftsmen.

To analyse whether there is a spatial distribution of manufacturing techniques, the distribution of manufacturing tools such as grinding slabs, and manufacturing debris, including flakes, angular fragments and tool blanks that show evidence for those techniques, were examined. Flaking is the most common technique, recorded within most of the shovel tests that show evidence for stone tool production and at a much higher rate than other production techniques. Used to shape and thin the tool blanks into a desired shape, flaking produces the most manufacturing debris and therefore it is not unexpected that it is the most visible form of production at Huizui. The widespread distribution of flaking indicates that the early production stages, which flaking is associated with, were not confined to particular areas within the stone tool production area, although flaking was more concentrated in some areas than others. This would suggest that specific production loci may have existed for the production of stone tools but that production was not limited to these areas alone.

Hammer dressing is only recorded in a total of five shovel tests but this may be a result of the nature of debris left by hammer dressing. Hammer dressing involves the crushing of ridges created by flaking on the surface of the stone tool. By crushing these ridges, a smoother surface more amenable to grinding is created (Dickson 1980, 165). Because of the nature of the process, flakes are not usually produced. This can be seen from Owen's (2006) replication of oolitic dolomite spades. While there are some small flakes left from the secondary flaking, the predominant debitage was fine dust that was too small to record in size. Hammer dressing is also usually only visible on the surface of tool blanks still in the process of manufacture, as in their final stages of production the hammer dressing evidence is ground away. The surviving evidence for hammer dressing may therefore not represent its overall distribution. However, from the information provided, it can be seen that hammer dressing occurs mainly within the central part of the stone tool production area, within the production loci of Rows 6 and 8. Shovel test 6C is especially interesting as it contains evidence for hammer dressing and a hammerstone. The hammerstone was a broken diabase cobble, with pitting evident on the remaining distal end. Diabase cobbles were regarded by Owen (2006) to be the most effective hammerstone for producing stone tools.

Grinding and polishing were more widely distributed within the stone tool production area, with polishing appearing more concentrated at the northern end. Again, this was based on the presence of manufacturing debris that had evidence for polishing or grinding on the dorsal surface. Grinding followed a similar pattern to that of the sandstone distribution, which is to be expected as the grinding slabs were largely made from sandstone. The main form of sandstone debris within the production area were small particles that most likely originated during the grinding process, during which the particles break away from the parent grinding slab.

Overall, apart from a slight concentration of hammer dressing techniques in the central section of the stone tool production area, there does not appear to be a spatial distribution of manufacturing techniques, as all are widespread. The presence of different types of manufacturing debris within the same areas indeicates that all manufacturing stages are conducted within the same production loci. This is confirmed by the identification of several different stages of manufacture within the two test pits.

From the above discussion of how production was organised spatially on site at Huizui, several points can be made. The first is the dominance of oolitic dolomite spade production within the overall stone tool production area. Oolitic dolomite manufacturing debris is present in significantly large amounts and is widespread across the entire stone tool production area, suggesting that this tool was the main focus of stone tool production at Huizui. This is consistent with the production numbers identified above and would again lend support to the argument that this tool was produced for consumption outside of Huizui, owing to the vast difference in the production numbers of this tool in comparison with the other tool types produced on site.

The second point is the presence of particular stone tool production loci within Huizui West. This is shown by both the test pit and shovel test data. From the shovel test data, it can also be seen that these loci are spaced at equal distances apart. The reasons for the regularity of these locations are not clear. These particular areas of production may reflect ownership or right of access to area. Other factors could be efficiency in spatial use, where the separation of production areas into this pattern is effective in terms of moving around the area, keeping lithic debris free from walking areas or other types of activity areas such as living places. This may also indicate the general distance between households that produced the stone tools, with the workplace immediately attached to each household. Further excavation of the spaces between the stone tool production loci is required to establish what caused the separation between these activity areas.

The general separation of activities would suggest that a general degree of labour specialisation existed, with some people focusing upon producing stone tools. To substantiate this proposal, an exploration of error rates during tool production would be useful to ascertain the skill levels of the craftsmen involved, which could then indicate the time spent by the craftsmen on stone tool production.

The third point is the presence of household production on site at Huizui West. This was demonstrated by the presence of household debris in the stone tool production contexts of the two excavated test pits. A wider examination of the overall stone tool production area during the 2004 excavation also demonstrated the co-existence of stone tool production and domestic living areas, which would suggest that stone tool production took place within a household context. This was consistent with previous analyses completed by Bestel (2006) and Liu et al. (2007).

Finally, the lack of spatial distribution of activities, indicating specialisation of space or labour within the stone tool production loci, has been demonstrated. While these areas were clearly dominated by oolitic dolomite spade production, there was no division in space between particular manufacturing techniques, tool types or raw materials. This would suggest that stone tool craftsmen completed all the stone tools on site, with particular emphasis on producing oolitic dolomite spades. The abundance and widespread nature of the manufacturing debris associated with the production of oolitic dolomite spades is therefore the main feature that distinguishes their production from that of other tool types produced on site.

© Internet Archaeology/Author(s) URL: http://intarch.ac.uk/journal/issue26/15/8.html

Last updated: Wed Jul 1 2009