Cite this as: Dungworth, D. 2015, Iron Bloom, in M. Atkinson and S.J. Preston Heybridge: A Late Iron Age and Roman Settlement, Excavations at Elms Farm 1993-5, Internet Archaeology 40. http://dx.doi.org/10.11141/ia.40.1.dungworth1

During the excavation a large cylindrical bloom of iron (SF2676; context 11000, unstratified machining layer) was recovered. A bloom is a mass of metallic iron produced by smelting in a bloomery furnace (Bayley et al. 2001). Blooms initially contain large amounts of slag waste but could be forged to remove some of the slag and consolidate the metal into an ingot or billet. The Elms Farm bloom is approximately 65mm thick and 210mm in diameter and weighs 12.2kg (giving an approximate density of 5.4gcm-3). Relatively few Roman (or pre- or post-Roman) iron blooms or ingots have been recovered from archaeological contexts in England (Table 196).

| Site | Reference | Weight |

|---|---|---|

| Forewood, Sussex | Smythe 1936-7 | 1.2kg |

| Lower Slaughter, Glos | O'Neil and Brown 1966 | 11kg |

| Cranbrook, Kent | Brown 1964 | 0.7kg |

| Corbridge beam | Bell 1912 | 7.5kg* |

| Catterick beam | Wright 1972; Starley 1997 | 7.5kg* |

A sample was taken from the bloom to examine the microstructure in order to confirm that it was a bloom. In addition, metallographic examination was carried out to determine the carbon content of the metal and so whether the bloom could be directly dated using radiocarbon dating. A metallographic sample was cut through the depth, but only 10mm into the width of the bloom (the bloom was extremely hard; probably due to the presence of slag inclusions). The cut sample was mounted in epoxy resin and polished to a 1-micron finish. The sample was examined using optical and electron microscopes, before and after etching with nital, and was chemically analysed using the energy dispersive spectrometer attached to the scanning electron microscope (SEM-EDS).

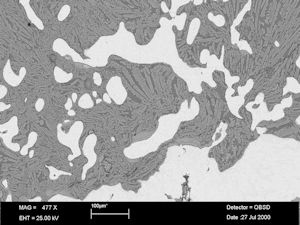

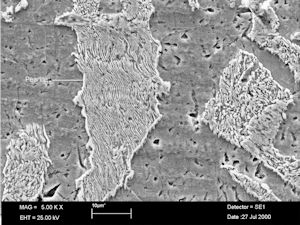

The bloom has a heterogeneous microstructure with widely varying amounts of slag (Fig 714), carbon (Fig 715) and phosphorous . The carbon-rich areas are limited to the edges of the bloom and the overall carbon content is likely to be less than 0.1%. SEM-EDS analysis showed that phosphorus was found through almost all parts of the bloom (Table 197). The phosphorus content of the bloom would have prevented the absorption of carbon because phosphorus inhibits the diffusion of carbon in iron (Stead 1915, 171; 1918, 389). Most of the phosphorus in the iron is in solid solution and microscopically the iron consists of crystalline grains that are bright when etched with nital (cf. ferrite). However, in some regions the phosphorus content was locally high enough for an iron-phosphorus eutectic (probably Fe and Fe3P) to be present (cf. Stead 1900). The iron-phosphorus-rich regions also showed the presence of iron sulphides (Figure 752). The variability in the phosphorus and carbon contents of the bloom are typical for iron produced by the bloomery process. The iron would not have been melted during the smelting process and so would tend to remain heterogeneous.

| Na2O | MgO | Al2O3 | SiO2 | P2O5 | SO3 | K2O | CaO | TiO2 | MnO | FeO | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Mean | 0.21 | 0.63 | 8.77 | 35.3 | 2.03 | 0.13 | 2.30 | 3.03 | 0.39 | 2.87 | 44.2 |

| sd | 0.08 | 0.08 | 0.86 | 1.8 | 0.76 | 0.08 | 0.18 | 0.26 | 0.04 | 0.58 | 3.3 |

The slag inclusions, which in some cases are over 1mm across, do not display any particular orientation and indicate that the bloom has been only partially consolidated (Figure 714). The slag inclusions consist of fayalite (2FeO.SiO2) laths in a glassy groundmass, but wüstite (FeO) is absent (see Table 197 for chemical analysis of the slag). The slag inclusions are frequently associated with poorly consolidated iron that has a dendritic or coral-like structure typical of blooms (cf. Blomgren and Tholander 1986). Overall the chemical composition of the slag inclusions (Table 198) shows greatest similarity with smelting slags from the Weald (Paynter 2006) and it is possible that the bloom was produced in the Weald.

The microstructures observed in the Elms Farm bloom are comparable with those seen in other archaeological examples as well as those from modern experimental bloomery smelting. The bloom from Lower Slaughter, Gloucestershire (O'Neil and Brown 1966), is described as heterogeneous and quite porous. The relatively abundant slag inclusions showed no particular directionality (indicating little forging) and the carbon content varied from virtually nil up to 0.4%. The bloom from Forewood, Sussex (Smythe 1936-7), also had a heterogeneous microstructure (ferrite and some pearlite with plentiful slag inclusions). Examination of the microstructure of experimentally produced iron blooms has shown these to have a relatively high slag content (present as randomly shaped inclusions), the metallic iron is on occasion found as dendritic or coral-like structures within the slag inclusions and the metallic iron has a very variable carbon content (Blomgren and Tholander 1986).

| Site | Reference | C% | P% | S% |

|---|---|---|---|---|

| Elms Farm | <0.1 | 0.73 | <0.1 | |

| Lower Slaughter | O'Neil and Brown 1966 | ~0.1 | 0.085 | 0.007 |

| Cranbrook | Brown 1964 | 1.27 | 0.020 | 0.027 |

| Little Waltham | Tylecote 1976 | <0.02 | 0.9-1.1 | na |

To summarise, the examination of the microstructure of SF2676 has confirmed that it is a bloom of iron produced by the bloomery process. It would have been smelted to produce a large spongy mass of solid iron which would then have been forged to shape. The bloom still contains relatively high proportions of slag and porosity and would have required further forging before it could have been used to manufacture artefacts. There is, however, no aspect of the microstructure of the bloom that would allow it to be positively identified as Roman in date, as iron-smelting technology changed relatively little between the Iron Age and the later Middle Ages.

Internet Archaeology is an open access journal based in the Department of Archaeology, University of York. Except where otherwise noted, content from this work may be used under the terms of the Creative Commons Attribution 3.0 (CC BY) Unported licence, which permits unrestricted use, distribution, and reproduction in any medium, provided that attribution to the author(s), the title of the work, the Internet Archaeology journal and the relevant URL/DOI are given.

Terms and Conditions | Legal Statements | Privacy Policy | Cookies Policy | Citing Internet Archaeology

Internet Archaeology content is preserved for the long term with the Archaeology Data Service. Help sustain and support open access publication by donating to our Open Access Archaeology Fund.