Cite this as: Tuck, A. and Rajic, M. 2021 Hollis Croft, Sheffield, South Yorkshire: Old site and new connections, Internet Archaeology 56. https://doi.org/10.11141/ia.56.4

The finds assemblage is of moderate size, and includes both industrial residues (metallurgical residues, crucibles and metal objects, bone and antler waste from handle manufacture) as well as domestic refuse (pottery, vessel glass, clay tobacco pipes, shoe leather, animal bone, oyster shell). The pottery assemblage was unusually broadly dated for Sheffield. There is also a small amount of structural material (ceramic building material, window glass).

The pottery assemblage consisted of a total of 425 sherds of pottery weighing 8620 grams and represented a maximum of 350 vessels. The pottery is listed in Appendix 2 of the archive report [PDF]. The totals from the various areas of excavation are summarised in Table 1.

| Number | Weight | ENV | |

|---|---|---|---|

| Trench A and Area A | 189 | 3397 | 165 |

| Area B | 14 | 423 | 12 |

| Trench C | 8 | 124 | 7 |

| Trench D and Area D | 62 | 1036 | 49 |

| Area E/F | 67 | 1787 | 55 |

| Trench F | 15 | 368 | 12 |

| Trench H | 1 | 12 | 1 |

| Trench K | 3 | 48 | 2 |

| Trench I | 57 | 1151 | 40 |

| Unstratified & Other | 9 | 274 | 7 |

| Total | 425 | 8620 | 350 |

The chronological range of the pottery constituting the assemblage was unusually wide for a site in Sheffield where extensive industrial and domestic development in the later 18th and 19th centuries have effectively removed much of the archaeological evidence for the medieval and post-medieval town.

The earliest pottery was of medieval (later 13th to 14th century) date and consisted of two sherds of Coal Measures Fineware (context 902), originating in the lower Don Valley (Cumberpatch 2004). Although rare, such sherds are not without parallel in Sheffield (Cumberpatch, in prep, 2017) and it is probable that the area supplied a significant quantity of the pottery used in the medieval town.

Post-medieval material consisted of three and possibly four sherds of Blackware (sewer pipe trench 930, layer 2011 and made ground 1116) with a sherd of Yellow ware from context 1113. These sherds date to the 17th century. A group of Redwares from demolition deposits 902 and 1102, sewer pipe trench 930 and wall 1113 date variously to the 17th- or early 18th-century with some which appear to be of 18th-century date, as summarised in the data tables. Slipware type 1, essentially Redware with trailed white slip decoration internally, was represented by two sherds from sewer pipe trench 930. The lack of chronological resolution reflects the limited research undertaken into this class of pottery.

Early modern pottery was considerably commoner than earlier types and included a wide range of the typical types in use during this period (c. 1720–c. 1840). As discussed in detail elsewhere (Cumberpatch 2014), early modern pottery assemblages typically have a tri-partite structure consisting of utilitarian wares, vernacular tablewares and formal tablewares which reflect contemporary social structures and their representation in the field of material culture. Multiple examples of all three classes were identified in the assemblage. Formal tablewares were represented by the sherds of White Salt Glazed Stoneware (sewer pipe trench 930, pit/well 1033, wall 1113 and demolition deposit 2115), Creamware (ditch 910, sewer pipe trench 930, pit/well 1033, wall 1108, layers 1704 and 2011, demolition deposits 2030 and 2115), Edged ware (pit/well 1033, wall 1108, layer 1704 and demolition deposit 2115) and Pearlware (ditch 910, sewer pipe trench 930 and pit/well 1033) which together span the whole of the Early Modern period. Pearlware, both plain and transfer printed, was comparatively rare although the reason for this is unclear as it is common elsewhere in the city.

Vernacular tableware, defined and discussed in detail elsewhere (Cumberpatch 2014) was manufactured in potteries that continued to be run along the lines established in the post-medieval period although in many cases with additional investment from local entrepreneurs. Vernacular tablewares were represented by Late Blackware (contexts 902, 916 and 1113), Mottled ware (demolition deposits 902 and 2115, ditch 910, sewer pipe trench 930, layer 924, made ground 1637), Slip Coated ware (demolition deposits 902 and 2115, sewer pipe trench 930) and Slipware (demolition deposits 902 and 2115, pit 904, sewer pipe trench 930, drain 1110, Trench C unstrat), the four commonest types of such wares.

The Brown Salt Glazed Stoneware category included a number of examples of 18th-century vessels (demolition deposit 902, sewer pipe trench 930, layers 924 and 1704), including mugs and bowls, amongst a larger quantity of 19th-century vessels, as summarised in the data tables.

Utilitarian wares, in the form of Brown Glazed Coarseware and Brown Glazed Fineware pose problems in the field of dating as a lack of detailed study means that it is difficult to distinguish 18th-century from 19th-century types with any degree of accuracy. In general, the smaller vessels in the Brown Glazed Fineware category (jugs and small jars) seem to be of 18th-century date while the manufacture of the larger wares, notably pancheons and large bowls, continued into the 19th and early 20th centuries. The date ranges attributed to individual examples in the data tables are based upon the characteristics of the specific vessels but more work is required on this economically significant aspect of the local and regional economy before it will be possible to produce an adequate account of the products of the industry. Layer 1704 contained the base of an unglazed flowerpot of mid- to late 19th-century date which may also be classed as a utilitarian vessel.

Recent wares (c. 1840–c. 1950) included a wide range of types common on sites of this date, as detailed in the various data tables. From the early 19th century onwards the production of vernacular tablewares declined rapidly and it seems that they were replaced with a variety of cheap and colourful refined earthenwares including Banded wares, Cane Coloured wares, including Mocha ware and Slip Banded Cane Coloured (CC) ware, Sponged ware, Sponge Printed ware and Whiteware, all of which were present in the Hollis Croft assemblage, as summarised in the data tables. Tablewares consisted primarily of Whitewares and Bone China, both plain and transfer printed, with smaller quantities of Porcelain, including parts of several ornaments (sewer pipe trench 930) and a small decorative vessel with white sprigged decoration (demolition deposit 2030). It is possible that the sherds of Lustre ware (layers 1704 and 2011, structure 1108) should be included in this category.

The range of transfer printed designs included some of the commoner patterns including Willow and Asiatic Pheasants with possible examples of Wild Rose and Abbey. The small size of many of the sherds precluded the identification of many of the designs. Layer 3008 (fill of north furnace) contained part of the base of a child's mug with an educational pattern consisting of two of the letters of the alphabet, B and C (B for Buffalo, C for Cat).

The tableware category also included sherds of Colour Glazed ware, notably parts of several teapots from sewer pipe trench 930, all with the typical dark brown 'Rockingham-style' glaze. Other sherds of this type may have belonged to vessels from compatible tea services.

The 19th-century Stonewares (both salt glazed and lead glazed) included retail vessels (bottles, flagons and jam jars) and kitchen wares (notably bowls). Amongst the bottles one example stood out. This was small buff-coloured bottle with an unusual recessed shoulder and a composite metal and cork stopper from demolition deposit 1523. The non-ferrous metal section of the stopper bore the words THE NEO CYCLOSTYLE GESTETNER'S / PATENT and the bottle contained a thick black ink-like substance with a distinct odour of linseed oil. The cyclostyle copying process was invented by David Gestetner in the late 19th century and was the subject of various patents between 1881 and 1905. It used a toothed wheel to perforate stencils which were then used to produce multiple copies of the document. The technique, with modifications, was widely used until the advent of electrostatic copying machines and remained in use, to the author's certain knowledge, until at least the late 1970s.

The pottery assemblage from Trench A (evaluation) and Area A (mitigation) consisted of 189 sherds weighing 3397 grams representing a maximum of 165 vessels.

Layer 902 was identified in both the evaluation trench and during the excavation and was described as 'demolition rubble'. Despite this it contained a diverse assemblage of pottery which included both of the sherds of medieval pottery as well as a substantial group of late post-medieval wares, notably Redware and a smaller and more diverse group of early modern wares (Late Blackware, Mottled ware, Slipware, Slip Coated ware). Recent wares were limited to two sherds of Whiteware. Overall, the profile of the assemblage does not accord well with that which would be expected from a demolition context and more closely resembles a dumped deposit as described elsewhere (Cumberpatch 2005; see also layer 911 below).

Layer 905 (fill of pit 904) contained a small group composed exclusively of 18th-century Slipwares (Plate 73), suggesting that the context may have some link with layer 902.

Layer 911, identified as a deliberate dump of material (in ditch 910), contained a small quantity of early modern pottery (Creamware, transfer-printed Pearlware, Mottled ware) with a larger quantity of mid- to late 19th-century transfer printed Whiteware. This combination of wares is not uncommon in assemblages from Sheffield and has been used to argue for a pattern of site formation that is both distinctive and representative of a significant pattern of economic behaviour in the city (Cumberpatch 2005).

Layer 916 (fill of sewer pipe trench 930) contained a very substantial and diverse assemblage of pottery which spanned the post-medieval, early modern and recent periods with the earliest pottery being two sherds of 17th-century Blackware. Redware and Slipware type 1 may span the later post-medieval period and the early part of the early modern period. Early modern wares included White Salt Glazed Stoneware, Creamware, Pearlware, Late Blackware, Mottled ware and Slip Coated ware. Recent wares formed the greater part of the assemblage and the overall profile, like that of layer 911, resembled the dumped deposits identified elsewhere in the city. The same may be true of layer 924 which contained a small but mixed assemblage of early modern and recent wares.

Area B produced a small assemblage consisting of 14 sherds weighing 423 grams representing a maximum of 12 vessels. All of the pottery was from a single context (1034, Plate 77, fill of pit/well 1033). The assemblage was predominantly of early modern date and included both utilitarian wares (Brown Glazed Coarseware) and tablewares (White Salt Glazed Stoneware, Creamware, Edged ware, transfer-printed Pearlware) with just one small sherd (2 grams) of transfer printed Whiteware.

The assemblage from Trench 3 consisted of just eight sherds weighing 124 grams representing a maximum of seven vessels. Unstratified material and one context were involved: layer 1637 (interpreted as made ground). Both groups were of mixed character with equally small quantities of early modern and recent pottery.

Trench D (Evaluation) and Area D (excavation) produced an assemblage consisting of 62 sherds weighing 1036 grams representing a maximum of 49 vessels. Layers 1702, 1703 and 1704 produced the largest assemblages of pottery, while layers 1724 and 1743 contained just five sherds of pottery.

In contrast to the assemblages discussed above, post-medieval and early modern wares were notable by their virtual absence from the Trench/Area D with just one sherd of possible Creamware from layer 1704. One cross-context join was identified, linking all of the sherds from layer 1703 with a number from layer 1704. This was the only cross-context join identified in the assemblage.

Tablewares and kitchenwares were well represented by a variety of refined earthenwares and salt glazed stonewares but utilitarian wares, in the form of Brown Glazed Coarseware were notable by their scarcity. There were no discernible differences between the assemblages from Trench D and Area D.

The assemblage from Trench F and Area E/F consisted of 82 sherds of pottery weighing 2155 grams representing a maximum of 67 vessels. Although two contexts (2011 and 2115) included quantities of post-medieval and early modern pottery, the material from other contexts was of recent date and included wide range of types typical of the mid-19th to early-20th century.

The earliest sherd was a fragment of 17th-century Blackware (layer 2011) which occurred alongside sherds of Creamware, Lustre ware and transfer printed Whiteware. Demolition deposit 2115 contained a mixed assemblage (the largest from the area) with early modern wares (White Salt Glazed Stoneware, Creamware, Edged ware, Mottled ware, Slipware, Slip Coated ware and some probably early Brown Glazed Coarseware) alongside Banded wares, Bone China and Whiteware. On this basis, the assemblage looks much more like a dumped one derived from elsewhere than it does a demolition deposit.

Amongst demolition deposit 1523, the most notable single item was the Gestetner ink bottle described above. Other items included two black printed sherds, one with a small section of lettering externally and the base of a mug or jug decorated with a broad salmon pink band externally. Elsewhere in Sheffield such vessels have been found associated with public houses and are often marked as having a capacity of one pint.

Demolition deposits 2030 and 2065, structure 2031 (part of cementation furnace), layers 2017 (chimney fill) and 2050 and drain fill 2136 all contained small mixed groups of recent pottery. Deposit 2030 was notable for the presence of two stoneware bottles with two further bottles from contexts layers 2050 and 2065.

Only one sherd of pottery was recovered from Trench H. This was a small piece of transfer printed Whiteware of mid- to late 19th-century date.

Area K contained three sherds of pottery (all from levelling layer 1234), two of them joining and most probably all from the same vessel, a blue banded mug or jug.

The assemblage from Trench I consisted of 57 sherds of pottery weighing 1151 grams representing a maximum of 40 vessels. As elsewhere, post-medieval, early modern and recent wares occurred together in the same contexts with sherds of 17th-century Blackware and Yellow ware from wall 1113 and made ground 1116 alongside varying quantities of other types. Wall 1113 was notable for the small quantity of recent pottery (the base of a plate) and larger quantities of early modern types, including White Salt Glazed Stoneware, Late Blackware and Redware in addition to the Yellow ware mentioned above. Small quantities of wares of similar date were noted in demolition deposit 1102, wall 1108 and made ground 1116.

Drain 1110 was unusual in containing only 18th-century wares but the entire assemblage totalled just three sherds, again raising the question of the degree to which such small assemblages can be relied upon as indications of the date of a feature or deposit.

One context, (layer 3008, fill of northern furnace) contained two joining sherds from a stoneware flagon and the base of a child's 'alphabet' mug, as described above. Such mugs are a rare but regular feature of sites in Sheffield with other examples including Franklin's maxims, nursery rhymes and religious themes in addition to the alphabet.

The pottery assemblage from Hollis Croft is an unusually diverse one for Sheffield but its overall character is not atypical for the city, at least as far as the profile of individual context groups suggests. How much of the pottery originated on the site and how much was imported as hard-core from one or other of the depots established in the city to accommodate domestic waste and to facilitate its reuse is unclear.

The CBM recovered amounts to just 19 pieces (17,538g) (see Table 2).

| Tr/area | Context | CBM type | No | Wt | Date range | Notes | |

|---|---|---|---|---|---|---|---|

| A | 916 | Brick | 1 | 8 | Undated | ||

| A | 916 | Chimney liner? | 1 320 | Undated | |||

| A | 916 | Sewer pipe | 2 | 182 | 1850+ | Salt glazed int & ext | |

| D | 1702 | Sewer pipe | 2 | 288 | 1850+ | Salt glazed int & ext | |

| D | 1743 | Tile | 2 | 99 | Undated | ||

| D | 1743 | Wall tile | 1 | 58 | Recent | Transfer-printed decoration | |

| E/F | 2030 | Chimney liner? | 1 | 99 | Undated | ||

| E/F | 2030 | Sewer pipe | 1 | 12 | 1850+ | Salt glazed | |

| E/F | 2115 | Roof tile | 3 | 576 | Undated | ||

| C | U/S | Brick | 1 | 3250 | 1849+ | Complete, standard frogged; stamped ROBINSON SHEFFIELD | |

| C | U/S | Voussoir brick | 2 | 8898 | C19/C20 | 2 near complete voussoir bricks, stamped THISTLE | |

| H | U/S | Brick | 1 | 5390 | C19/C20 | Near complete large brick (?refractory), heavily burnt and covered in slaggy concretion (>260 x 120 x 80) | |

| - | U/S | Sewer pipe | 1 | 82 | 1850+ | Salt glazed int & ext |

Four complete, or near complete, bricks were recovered. All were found unstratified, three in Trench C and one in Trench H. The three from Trench C comprise a standard frogged brick and two voussoir bricks. The frogged brick is stamped (in the frog) ROBINSON SHEFFIELD. There are several brick makers named Robinson listed in the Sheffield trade directories between 1849 and 1919. Both voussoir bricks are in a yellow stock fabric, and are stamped THISTLE, products of Scottish brickworks. In addition, a small brick fragment was found in sewer pipe trench 930. The brick from Trench H is a large, possible refractory brick which has been heavily burnt.

Six fragments (from sewer pipe trench 930, layer 1702, demolition deposit 2030 and unstratified) are from salt-glazed sewer pipes (c. 1850+) and five from flat roof tiles (layer 1743, demolition deposit 2115), broadly dated as post-medieval/modern. Two fragments (sewer pipe trench 930 and demolition deposit 2030) are possibly chimney liner. Finally, a wall tile from context layer 1743, with a transfer-printed design, is of 19th-/20th-century date.

The Hollis Croft excavations produced a total of 300 fragments of pipe, comprising 53 bowl, 239 stem and 8 mouthpiece fragments from 26 different contexts. Although the pipes from Hollis Croft represent three centuries of clay tobacco pipe consumption, the majority date to the first half of the 19th century. The bowl forms and the decorative motifs that are represented in this group are typical of pipes being produced and/or consumed in Sheffield. A number of the bowl forms exhibit traits that have been identified as being peculiar to Sheffield, such as specific types of post-moulding flaws, which appear to indicate particular working practises within the workshops, as well as distinctive internal bowl cross that appears to be a form unique to the Sheffield area. These features are discussed below.

Unfortunately, the majority of the pipe-bearing contexts from the excavation produced plain stems or small fragments that do not provide sufficient evidence for detailed analysis of the individual excavated contexts themselves. Only five of the context groups produced ten or more pipe fragments, the most significant of which is layer 1704, which is discussed in more detail below. Although the material from the remaining deposits is interesting in itself, it does not shed much light on a broader interpretation of the site. As a result, the context groups have been dated (see Appendix 3 of the archive report [PDF]) but will not be discussed further in this section of the report.

Layer 1704: This context was described as a possible occupational fill and produced 121 fragments of pipe (21 bowl, 95 stem and 5 mouthpieces). This is by far the largest group of pipes recovered from the excavations and represents a very coherent looking group of material. There is just one small stem fragment that is clearly residual (being of 17th- or earlier 18th-century date), with all the other fragments representing a contemporary looking group of pipes. This group unfortunately suffered damage in transit for reporting and so a lot of fresh breaks were present when it was examined. These have been reassembled using HMG glue with slivers of wood placed in the stem bore to strengthen the join. The reassembled pieces have been counted/treated as single fragments for the purposes of this report.

Some long stem fragments survive (up to 145mm) and one of the bowls still has 107mm of stem attached, suggesting that this group was little disturbed following deposition. Despite this, checks of the most obvious potential joins (mouthpiece to stem or bowl junction to bowl) failed to find any matches, suggesting that this is only part of a much larger original assemblage. There are no marks to help with dating, but one of the bowls has a panel style of decoration, which did not come into use until after c.1810 and was most common during the 1820s and 1830s, with the latest examples probably dating from around 1860. The majority of the bowl forms are plain and comparable with those from a deposit of c. 1845-60 from Swinegate in York (Higgins forthcoming). In broad terms, this group is likely to date from somewhere between 1820 and 1860. Taken together, they provide a useful reference point for an assemblage of pipes of this date from Sheffield.

The group is clearly domestic in nature, rather than being production waste, since most of the bowls show signs of having been smoked and a wide range of different mould types is represented. A minimum number of 21 pipes is represented in the group and 16 of these could be identified to individual moulds (10 different types), which have been allocated the reference numbers 1–10 (the mould type and the clay pipe figure number in this report happen to be the same for these 10 types). Each of the 21 bowl fragments has been allocated an alphabetic suffix (A–U) to act as a unique identifier for that particular piece. The context number and these identification letters have been pencilled onto the fragments themselves. These are as follows:

| Mould No | Fragments |

|---|---|

| 1 | A–B (2 examples) |

| 2 | C–F (4 examples) |

| 3 | G–H (2 examples) |

| 4 | I–J (2 examples) |

| 5 | K |

| 6 | L |

| 7 | M |

| 8 | N |

| 9 | O |

| 10 | P |

| Unallocated | Q–U (5 examples) |

The majority of the pipes in use had plain bowls (mould types 1–7), which included 13 of 16 identifiable bowls (Table 3). Most of these plain mould types are represented by multiple examples (Figure 58, nos. 1–7). In contrast, the three decorated bowls (mould types 8–10) are just represented by a single example each (Figure 58, nos. 8–10). This suggests that the majority of the pipes in use were plain, and perhaps purchased as multiple examples or in bulk, whereas the decorated pipes appear to have been more 'one-off' in their purchase/use.

The other striking point about the bowls is how similar all the plain bowl forms are, despite their having been produced by seven different mould types. This indicates that there was not any great variety in design and the only real difference being in that one of the types (mould 7) is slightly smaller and shorter than the others, perhaps suggesting a style with a shorter stem as well. Overall, the types of pipe in use appear to have been very similar, suggesting fairly uniform products from the local manufacturers, and of an 'everyday' quality. The mould surfaces tend to be rather streaky from poorly finished moulds and there are often clear trimming marks on the pipes. Many of the bowls also show accidental knock marks, created by some sort of a serrated edge that most often occur towards the front of the bowl. These are a particular characteristic of Sheffield pipes (White 2004a) and must represent a particular production technique or method used in this area.

The decorated bowls are quite different in character from one another. One of them (Figure 58, no. 8) just has simple leaf decorated seams, which was a common motif used across most of England throughout the 19th century. The second (Figure 58, no. 9) also has leaf seams but accompanying a distinctive 'panel' style of decoration whereby the larger part of each side of the bowl contains a decorative panel, in this instance containing a bunch of grapes surrounded by vine leaves. This motif is particularly common in Sheffield, where it is known to have been produced by several different manufacturers, including Joseph Dee, who is recorded working in Little Pond Street, Sheffield, from at least 1833–1852. The final piece (Figure 58, no. 10) has a particularly interesting and unusual bowl design that does not appear to have been recorded previously, even though examples of the associated stem decoration have been noted. Both bowl seams are decorated with large and ornately worked leaves, with relief moulded tendril scrolls extending along both sides of the stem. There is also a stem fragment with a continuation of the stem decoration that either comes from further down the stem of this example or from another made in the same mould (but shown here restored in a composite drawing, which includes the missing section from an identical stem found during the Sheffield Inner Relief Ring Road excavations). On the left hand side of the bowl is a running stag that is being pursued by two hounds on the right. There is a band of fine milled lines above a beaded line around the rim. The mould for this distinctive design has been quite finely engraved and represents one of the first attempts to introduce a greater variety of one-off decorative designs by the Sheffield area makers.

Apart from the tendril decorated stem mentioned above, all of the other stems are plain. They all appear to come from long-stemmed pipes, with fragments of up to 146mm in length surviving. The stems would most likely have been around 15 inches (381mm) in length originally, this being a fairly standard length for common pipes of the period (Higgins forthcoming). Some of these stems were clearly curved while other long fragments appear to have come from straight stemmed pipes. Only five mouthpieces were recovered, but all of these have a relatively narrow tip with simple cut ends and are consistent with long stemmed pipes (rather than short 'cutties'). All five mouthpieces have a coating of green glaze, the colour ranging from a dark green glossy glaze to a thin patchy pale green. In all cases the glaze is quite crudely applied with irregular splashes extending along the stem. One only has 23mm properly coated from the tip but typically 30-40mm of the stem is uniformly coated, with splashes extending up to about 50mm. There are a further three stems with the tip itself missing but splashes of green glaze showing that they were glazed originally and two stems with splashes of a yellowish brown glaze on them (i.e. ten fragments in total have traces of glaze on them; eight green and two yellow).

One of the stems from near a tip has a smoothed facet on one side where the stem has been scraped against an abrasive surface. The fact that this ground surface only occurs on one side most likely suggests that they stem has been briefly used as a makeshift stick of chalk to write on or mark a hard surface. Similarly, one of the mould type 3 bowls (fragment H) has scrape marks underneath it where the spur itself has been rubbed smooth. Rub marks are also evident on the broken stem end, flush with the bowl, showing that this was not to reuse the pipe but also some sort of doodling or reuse of the fragment to mark a hard surface.

Taken together, the pipes from layer 1704 provide a snapshot of the everyday pipes being consumed domestically in Sheffield around 1820–60. The pipes are mainly of mediocre quality with surface flaws on the moulds and finishing marks on the bowls. The pipes were mainly fairly uniform in size and shape, despite a number of different moulds being represented (seven different plain types and three decorated). Decoration included a locally popular vine motif as well as a more unusual stag and hounds scene. All were long-stemmed varieties of pipe with glazed tips in green or yellow. Some of the stems were curved and others straight. None of the pipes was marked, although all are likely to have been produced locally.

The majority of the pipe assemblage (297 of the 300 fragments; or 79%) comprises plain stems, which are difficult to date accurately. The use of stem bore dating techniques is unsuitable for small mixed context groups of the type recovered here and, in any case, the method is not reliable for 19th-century pipes, which comprise the majority of the finds. This method also requires a sample of several hundred fragments in order to produce a reliable date. The dates for the plain stems are therefore given simply as broad date ranges within which the fragments are likely to have been produced based on an assessment of their form and characteristics (see Appendix 3 of the archive report [PDF]). Stem dates should be used with caution since they are much more general and less reliable than the dates that can be determined from bowls or marked fragments.

The excavations produced a total of 53 bowls, or bowl fragments, 40 of which (75%) were plain. The earliest bowl form was recovered from context 1637 and dates from c. 1740–1770 (Figure 59, no. 11). This neatly finished bowl, with its trimmed spur and well burnished surface is typical of the bowl forms that would have been produced in the area in the mid- to late 18th century. This type of bowl has been associated with stem marks that have been attributed to pipemakers in Rotherham such as the Wild family, whose products turn up in large numbers in Sheffield (see discussion of the Thomas Wild stem below).

The largest single group of plain bowl forms was recovered from layer 1704 (discussed above), a selection of which have been illustrated as Figure 58, nos. 1–7. These forms are typical of pipes being produced and consumed in and around Sheffield in the middle of the 19th century. They are all spur forms with simply cut rims and some (Figure 58, nos. 3–5 and 17) have distinctive internal bowl crosses.

Internal bowl crosses or marks are formed by a design cut on the end of the stopper that was used to form the bowl cavity during the manufacturing process. The internal bowl crosses identified in the pipes from a number of sites in Sheffield are quite distinctive as they have two cross bars '‡'. This very distinctive feature suggests that either the bowls produced by a number of different manufacturers were all made using stoppers supplied by the same mould maker, or that these bowls were produced in a single workshop where this particular motif was added to the stoppers.

Some of the bowl forms recovered from the excavations also have distinctive post-moulding flaws. One result of producing clay tobacco pipes in a metal mould is that the clay took up any small nicks, scratches or surface defects on the mould's surface, thereby producing a unique 'fingerprint' for that particular mould. These post-moulding flaws, however, represent a different class of manufacturing flaw, since they were introduced to the pipe as a result of it being pressed or knocked against something after it was removed from the mould itself, but while the clay was still soft. These flaws, which usually take the form of small triangular marks or lines of serrated indentations on the side of the bowl (for example, Figure 59, no. 17), have been recorded by the authors on a number of pipe bowls from sites across Sheffield. Although the position of the flaw varies slightly from bowl to bowl they are most frequently on the smoker's left. What appears to have been happening was that the person finishing the pipe was knocking or catching the pipe on something that was leaving a distinctive mark prior to firing. This feature not only links the pipes to the same manufacturing tradition but, potentially, to an individual workshop or finisher.

The remaining 25% of the bowl fragments recovered from the site are mould-decorated and these too are spur forms with cut rims. The decorative motifs represented by these bowls are discussed in more detail below. It is interesting to note that although the decorated bowls are contemporary with the plain ones, none of the former appear to have the distinctive internal double bowl cross.

The excavations produced a total of seven marked fragments comprising one stem with a roll-stamped mark, two bowls with moulded lettering around the rim, two moulded spur marks and two moulded stem marks.

The earliest of these marks is the stem with the roll-stamped mark from the fill (916) of sewer pipe trench 930 (Figure 58, no. 12). This mark reads THO WILD and depicts a stag flanked by flowers above the lettering with a border of hearts below. This mark has previously been recorded for the National Clay Tobacco Pipe Stamp Catalogue, a copy of which is held in the National Pipe Archive (Higgins Die No. 2089). This stamp was almost certainly produced by Thomas Wild of Rotherham around 1750–80. There were three pipe makers named Thomas Wild who are known to have been working in Rotherham during the 18th century. This particular stamp has been attributed to Thomas Wild (3) who appears in the Quarter Session at Sheffield in 1777. Examples of this mark are known from other sites in Sheffield including Riverside Exchange (White 2015).

The other marks are all moulded, i.e. the design was cut into the pipe mould itself so that it was automatically added as part of the moulding process, rather than having to be applied as a separate task during the finishing process.

The first of the two marked bowl fragments was recovered from layer 1724 and dates from c. 1810–1860. This bowl has the lettering WARRINGTON ROTHERHAM in relief around the rim (Figure 59, no. 15). The design comprises enclosed flutes on the lower part of the bowl with panels above. The panel on the smoker's right has a heart-in-hand motif and is surrounded by laurel wreaths. The panel on the smoker's left has Masonic motifs comprising two pillars flanking an interlocked square and compasses. Bowls of this type normally have the maker's name on the smoker's left with the place of manufacture on the smoker's right. This would, therefore, appear to be the product of a maker by the name of Warrington who was living and working in Rotherham. Three other examples of this bowl are known; a near complete bowl from Sheaf Square, Sheffield (White 2005a, fig.33); a fragment from excavations at the Union Grinding Wheel site in Alma Street, Sheffield (White 2007b); and near complete bowl in Lincoln museum recovered from the Waterside, Lincoln in 1952 (P. Hammond pers. comm.). This maker has not yet been identified from documentary sources, which should provide a more accurate dating for this piece.

The second marked bowl was recovered from layer 1702 and dates from c. 1840–1870. This bowl has the lettering ERATT BRIGG in relief moulded around the rim above a vine, grapes and barrel motif (Figure 59, no. 14). The vine and grapes motif appears to have been particularly popular in Sheffield, where several similar versions, some with different makers' names, have been found. There are three generations of the Eratt family who are known to have been working as pipemakers in Sheffield during the mid- to late 19th century. William Eratt (b. c.1817) and his brother James (b. c.1819) started life in Whitby. William was bound apprentice to Edward Sayers at Hull in 1831 and worked there until c.1839 when he moved to Sheffield, where he is recorded until his death in 1874. James was also working in Hull between 1846 and 1848 but by 1851 had moved to Sheffield where he continued to work until his death in 1866. Although none of William's children appear to have gone on to become pipemakers, the children and grandchildren of his brother James all went into the pipe making profession and were working as pipemakers in Sheffield until 1920. At least two other fragments from identical ERATT BRIGG bowls are known from excavations in Sheffield with a third near complete bowl in a private collection from near Beverley (White 2004b, 226). The Eratt family are thought to have had family connections with Brigg in Lincolnshire (P. Hammond pers. comm.), and it appears that one member of the family must have worked there for a while.

The two relief-moulded spur marks are both of 19th century or later date and comprise one initial mark and one symbol mark. The initial mark was recovered from demolition deposit 2115 but is a little hard to date since so little of the bowl survives that it is not even possible to tell whether it was decorated or not (Figure 59, no. 20). The base of the spur is not trimmed (suggesting it dates from after c. 1800) and the script is sans-serif, which normally indicates a date after about 1850, and so a date of c. 1850–1910 is suggested for this piece. The spur is marked with the initials EM but it is interesting to note that these are placed upright on the spur at 90° to the stem, rather than being parallel with it, which is the usual orientation. There are no currently documented pipemakers in the Sheffield area with the initials EM at this time and so the maker of this piece remains unknown.

The second spur mark dates from c. 1850–1920 and comprises a symbol mark formed of a quartered square with a central incuse dot on each side (made ground 1116; Figure 59, no. 18). Not enough of the bowl survives to see whether it was decorated. This style of symbol mark was not specific to any one manufacturer and was used more as part of the design of the pipe. It occurs widely across the country.

The final two marked pieces are stem fragments with incuse moulded numbers on their left hand sides (only). These were recovered from demolition deposit 2115 and layer 2011 and read '21' and '№ 2' respectively (Figure 59, nos. 21 and 22). Both fragments are likely to have come from short-stemmed 'cutty' pipes dating from around 1870–1920. A number of the larger pipe making firms from this period produced pipes with pattern numbers that would have corresponded with a trade catalogue. Without the bowls, it has not been possible to identify which firms were responsible for these two examples.

The excavations produced a total of 13 clay pipe fragments with moulded decoration. The decorative motifs range from simple leaf-decorated seams (Figure 58, no. 8) to panels with elaborate vine decoration (Figure 59, no. 14) and bowls with masonic motifs (Figure 59, nos. 13 and 15). All of these designs were popular in Yorkshire during the 19th century and almost identical versions would have been produced by a number of makers. This is particularly true of the vine leaves and grapes design (Figure 58, no. 9), which was particularly popular in the Sheffield area. Very often there were no marks to differentiate one maker's product from another, although in some cases the maker has included his name and place of manufacture as part of the design (for example, Figure 59, nos. 14 and 15).

The excavations produced one decorated pipe that was a commemorative piece (Figure 59, no. 16). This particular pipe bowl was recovered from context 924 and can be dated to c. 1840–1860. On the smoker's left there is the bust of a naval officer above the lettering NAPIER and on the smoker's right there is a ship in full sail. This Napier bowl is identical to two examples recovered from the Inner Relief Ring Road excavations by Wessex Archaeology and to a large group of pipes that were recovered during excavations in Sheaf Square, Sheffield, in 2004. The Sheaf Square examples were associated with kiln waste of Henry Tunstall of Leeds dating from c. 1855 that appeared to have been transported to Sheffield specifically for use as backfill material prior to the construction of the new railway buildings (White 2005a). It is most likely that this pipe depicts Admiral Sir Charles Napier KCB GOTE RN (1786–1860). In contemporary portraits of Admiral Napier, he is typically depicted with epaulets and naval decorations, as shown on the pipe.

The final mould-decorated bowl from the excavations at Hollis Croft is one that has not previously been recorded, although a matching fragment of decorated stem that can now be identified as having been made in the same mould was recovered from the Inner Relief Ring Road excavations by Wessex Archaeology, and used here to produce a composite drawing of the whole design. The Hollis Croft pipe bowl was recovered from layer 1704 and dates from c. 1820–1860. There are a pair of hunting hounds on the smoker's right that are chasing a running stag, which appears on the smoker's left (Figure 58, no. 10). The stem is elaborately decorated with a tendril design on both sides.

The use of hunting dogs is not a common decorative motif, although the authors are aware of two other contemporary examples from Yorkshire. The first is a pipe recovered from excavations at Dry Sands Foundry in Leeds (White 2009, figs. 8 and 9). That example has Masonic motifs on the bowl, but along the stem is relief moulded decoration, including running dogs. The Dry Sands example is marked TH and has been attributed to Thomas Hunter, who is recorded as a pipemaker in Leeds between 1817 and 1829. In this instance, the hunting dogs may be a play on his name.

The second example is a bowl recovered from the Inner Relief Ring Road excavations in Sheffield, which has panels on either side of the pipe with the name SPURR on the smoker's right and a running animal, thought to be a dog, on the smoker's left. This particular example has been attributed to Charles Spur who is known to have been working in Sheffield from c. 1835–1865. The 'stag and hounds' design from Hollis Croft is certainly a distinctive design and one that adds to the evidence that designs incorporating running dogs were locally popular during the early to mid-19th century.

The post-firing modification of pipe fragments, most frequently stems, can take a number of forms, but usually seems to occur for one of two main reasons. The first is the grinding or scraping of the stem for reuse after the original mouthpiece has broken off. This type of modification is characterised by even grinding round the broken end of the stem and, occasionally, by the appearance of tooth wear as well. The second type of modification is when the stem has been used as a medium with which to draw or write graffiti, resulting in the formation of distinct facets at one, or both, ends of the stem. Sites from Sheffield, such as Riverside Exchange, have also identified a third and more specialised form of modification that indicates some form of industrial 'doodling'. This third type of modification appears to have resulted from the pipe having been pressed against a mechanical grinding wheel, producing perfectly smooth and sharply defined cut facets (White 2015, 23).

The excavations at Hollis Croft have produced three fragments that have been ground or modified (Figure 59, nos. 17–19), but none of these fit with the 'normal' types of modification described above. The first example (Figure 59, no. 17) is a plain bowl identified as an example of mould type 3 from layer 1704 (Figure 58, no. 3). This bowl has been ground smooth right across the broken ends where both the spur and the stem would have been. The second fragment (Figure 59, no. 19) is a short length of stem that has not only been ground smooth at each broken end, but also in bands along the length of the stem. The modification of these two fragments is clearly not for reuse and nor do the ground sections show sign of faceting that would be expected if the fragments had been used for writing graffiti. It is therefore assumed that both fragments are further evidence of doodling or idling away time.

The third fragment has clearly been modified for re-use with the broken stem end having been whittled (Figure 59, no. 18). The presence of a vertical scratch running around the stem suggests that a metal ferrule has been used to connect this pipe to a separate mouthpiece. This is a more sophisticated modification for reuse that would have taken time and care to prepare since it would require a separate mouthpiece, possibly of Bakelite or vulcanised rubber, to be attached. This modification is in contrast to a simple smoothing of a broken stem end that would have made a damaged pipe instantly reusable.

This small, but interesting, group of pipes from Sheffield adds to the growing picture of pipe production and consumption in the city during the 19th century. With each new excavation material is recovered that builds on and refines our understanding of trading patterns between a thriving industrial city and its neighbouring towns and villages. For most of the 18th-century Sheffield relied on pipemakers from outside the city, mostly from Rotherham, to supply its population with pipes. By the early 19th century, however, the city had started to develop its own pipemaking tradition. This latest excavation at Hollis Croft has provided new products as well as further evidence for workshop practises in Sheffield's emerging pipe manufacturing industry.

The glass assemblage amounts to 122 fragments (7772g). The glass includes both vessel and window; nearly all appears to be of 19th- or 20th-century date. In addition to the 122 fragments of glass recovered, there are 19 rubber bottle stoppers for internal screw closures (two of them still in situ), which are considered alongside the bottles here. Appendix 4 of the archive report [PDF] lists the glass by context.

Two fragments of free-blown or mould-blown green wine bottles are the only fragments which could be earlier than 19th century, but their potential date range does extend into that century (Area B, layer 1028; Trench D, layer 1702). Both are likely to be residual finds here.

The majority of the vessel glass consists of beverage bottles, in aqua, green, blue and clear glass, and includes some complete or near complete examples. There are Codd, internal screw, crown and cork closures, but the absence of Hamilton (torpedo) bottles suggests a date range no earlier than perhaps the 1870s.

Beer and carbonated drinks are represented, and embossed marks belong to several Sheffield manufacturers: B Chapman & Co of Effingham Street (2 examples), Gleadhall & Bayley of Attercliffe (2 examples), John Walker (1 example), S H Ward & Co (3 examples), as well as Ind Coope of Romford (1 example). The screw stoppers mostly belong to Ind Coope (15 examples), and add to the list of Robson Brothers at the Park Brewery, Wilson Bothers of the Parkside Brewery and Tennant, all Sheffield manufacturers. The bottles used by B Chapman & Co were both made by Kilner Brothers of Conisborough.

Other bottle types are scarce. There are a few fragments from milk bottles, one Bovril bottle (4 oz) and one possible condiment bottle. Apart from one phial neck (sewer pipe trench 930, Area A), no pharmaceutical containers were definitively identified, although a small number of miscellaneous small bottles (some rectangular) are of uncertain function and could include pharmaceutical as well as foodstuff containers.

A hollow ware fragment from sewer pipe trench 930 in opaque white glass with hand painted decoration could be part of a candlestick.

There are 22 fragments of window glass, mainly thick-walled and including frosted and reinforced glass. In addition, there are two waste droplets, and a glass marble from a Codd closure.

Individual items have been examined to assess their archaeological potential, and as part of the assessment, the specific and wider archaeological context of the items have been considered. Bulk soil samples have been examined visually. A brief description and interpretation of the material in the assemblage, by context, is provided in Appendix 5 of the archive report [PDF].

An overview of the assemblage is given below, and more unusual or significant finds are discussed in detail in the later interpretation and discussion section. Samples of slag-like residues from the two cementation furnaces excavated have also been analysed scientifically. The report on this analysis, and interpretation of the results is included in Appendix 5 of the archive report [PDF].

The assemblage contains four main types of material; metal objects, fuel ash slag, slag-like residues, and refractory items. Many of the objects within the assemblage can be attributed to either cementation steelmaking or crucible steelmaking; however, a significant proportion of the assemblage was recovered from secondary fill and/or 'made ground' type contexts, and much of this material cannot be attributed to a specific manufacturing process, structure or activity.

The metals assemblage is largely composed of what appears to be machinery or architectural fittings/parts that are of limited research potential. However, there are two fragments of metal that are of potential research interest, and these are discussed in more detail.

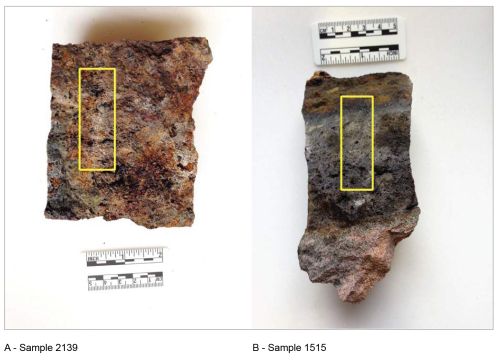

The diagnostic slag residues predominantly relate to cementation steelmaking, and these include examples of the slag-like deposits from the inside base of the cementation chests, as well as coal derived fuel ash slags that had reacted with refractory materials surrounding the fire-grate and the outer surface of the furnace chests during firing. The examples of the slag-like residue from the inside of the furnace chests in Trench F/Area E/F (1515 and 2139) are bonded to the large fragments of the refractory stone that the chests were made from. The slag-like residue from the inside of the chests is of research interest and although exploratory analyses have been previously been carried out by the author (on material from the Sheffield Inner Relief Road; and from Green Lane Works, Elmet Archaeological Services 2014, 3–4), a definitive characterisation has, to date, not been possible.

The spent fuel in the assemblage largely consists of fragments of coke, and a small amount of this is embedded within pieces of fuel ash slag. There are also a few fragments of burnt coal.

The crucible assemblage is relatively small and, with the exception of one piece, it all appears to relate to crucible steelmaking. One fragment of almost complete crucible base has traces of oxidised residues that suggest that it had been used to melt copper based alloys (Plate 72).

The sub-assemblage of metals includes a short length of corroded ferrous metal bar that measures approximately 82mm x 15mm x 23mm. This piece was recovered from demolition rubble 2115 overlying the north of Area E/F. The wider archaeological context together with its dimensions suggests that this piece of metal may be an offcut of blister steel bar, and it is possible that this piece of steel was produced by one of the cementation furnaces on the site. Bars of blister steel produced by the cementation furnaces would have been broken up into short pieces so that they could be used as feedstock for the crucible furnaces.

The second item of interest in the metals sub-assemblage was recovered from an unstratified context, and was provisionally identified as a cast iron fire-bar support from a furnace (Figure 60). Subsequent work on site found an example of almost identical fire-bar supports in-situ within the fire-pit of one of the cementation furnaces. The fire-bar supports were built into the walls of the fire/ash pit of the cementation furnaces, and they spanned the gap between the two chests within the furnace. Fire-bars were laid on top of the supports and ran length ways down the fire/ash pit to form a grate. Fieldwork and site visits by the author have found that the fire-bars could be well over two metres in length, and they do not appear to have been fixed in place. Presumably, the fire-bars were not fixed so they could be moved to help clean fuel ash slag out of the grate during and after firing. What is unusual about the fire-bar supports found on site are the teeth-like projections from one of the edges of the supports.

The exact purpose of the projections is not known, but the author initially thought that their purpose may have been to keep the fire-bars evenly spaced to allow an even flow of air through the fire. However, this initial idea had to be reconsidered when the in situ fire-bar support was found, as this has the projections facing downwards (Plate 35). Further investigation revealed photographs of a similar toothed fire-bar support that had been found in cementation furnace previously excavated in Sheffield (Elmet Archaeological Services 2014, 27, plate 4), and in this furnace, the projections on the fire-bar support faced sidewards.

One explanation for the above may be that the supports were originally fitted with the projections facing upwards, but in use it was found that the long fire-bars expanded and warped in the heat, making it impossible to remove them. Rather than removing and discarding the supports, the furnace men may have carried out some minor alterations to the brickwork to enable the supports to be rotated so that the toothed edges face down or to one side; this might also explain why the projections face down in one furnace and sidewards in the other.

An exploratory (unpublished) analysis of a discarded fire-bar from a cementation furnace was carried out by the author, and this revealed that the fire-bar was made from relatively low grade wrought iron. As 18th- and 19th-century wrought iron was not a uniform metal with a homogenous microstructure, the long fire-bars would have been susceptible to uneven heat expansion and deformation. It is interesting that the fire-bar support that was initially found has one of the 'teeth' broken off, and the fracture surface is not fresh, so it appears unlikely to have been broken during recent excavation work. The tooth could have broken off during the original demolition of the furnace, but it is also possible that the tooth may have been broken off intentionally to remove a jammed fire bar.

Most of the fuel ash slag within the slag sub-assemblage appears to be the by-product of coal or coke fuelled fires. As the cementation and crucible furnaces found on site would have both consumed significant quantities of coal and coke, it seems likely that the fuel ash slag found probably originated from the furnaces on-site. The spent fuel in the assemblage consists almost entirely of fragments of coke fuel that probably relate to the crucible furnaces.

Alongside the evidence of cementation and crucible steelmaking, there is tentative evidence that non-ferrous metals might have also been produced at, or very close to the part of the site excavated. The evidence consists of the base of a crucible that had been used to melt copper based metal, possibly bronze or brass. The proximity of little mesters' workshops (ARCUS 2008a and 2008b) would have meant that there was probably a local demand for non-ferrous metals for fixing and decorating handles on tools and cutlery. Depending on demand, it is possible that there was a dedicated furnace somewhere in the works for re-melting brass and bronze or, as copper based alloys typically melt at a much lower temperature than crucible steel, one of the crucible holes in the steelmaking furnace may have been used.

The coal derived fuel ash slag found appears to relate to the cementation furnaces, and the morphology and odour of some of the fragments of fuel ash slag suggest that 'dirty' bituminous coal was being used to fire the furnaces. Presumably, as there was a clear separation between iron/steel and fuel in the cementation furnace, contamination from sulphurous coal fumes was not an issue, and it would have been possible to use the cheapest coal that would do the job. As the fuel ash slag in the assemblage demonstrates, one of the disadvantages of using low grade coal can be the amount of fuel ash slag (or 'clinker') produced. If allowed to build up, the clinker could severely restrict the amount of air that could pass through the grate and fire, and this may be the main reason why the furnace men would have wanted fire-bars that could be easily moved around, so that they could clear any clinker and ash build up from the fire-grate whilst the furnace was being fired.

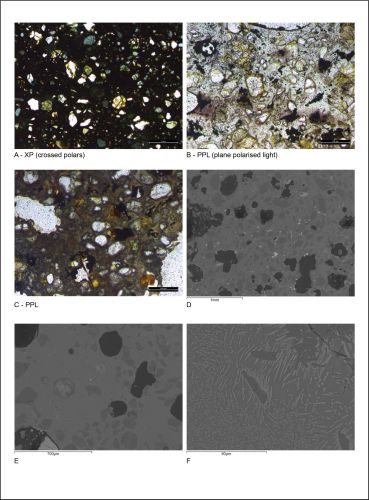

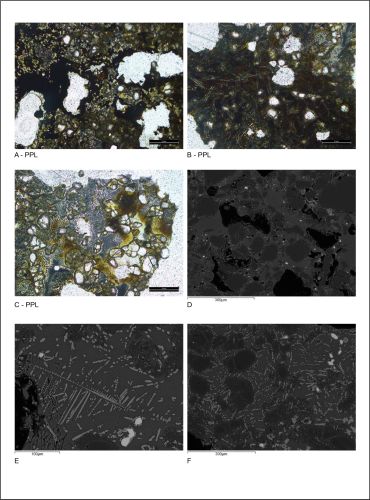

The sub-assemblage of slag also contains samples of a slag-like residue that was found inside the remains of the stone chests in the two cementation furnaces. Very similar looking residues have been seen in the remains of cementation chests from at least three other excavated furnaces in Sheffield, and samples of residues from two of these have previously been analysed by the author (Elmet Archaeological Services 2014, 30–4). The analysis to date has revealed that the slag-like residue found lining the inside of the cementation chests is not a slag by-product of the process, but a deliberate addition of a clay-like material. The purpose of this deliberate addition is thought to have been to seal any cracks and joints in the stone blocks that the chests were made from. The operation of cementation furnaces and importance of keeping the chests air tight during firing was described by the author in detail in Elmet Archaeological Services 2014, 31:

...it was very important that air did not enter the sealed chests during the firing of the furnace, as this would inhibit the carburisation process and, in the worst case, the charcoal packing would burn out and the bars of iron within the chests would start to fuse together.

The material used to construct the chests had to be refractory to resist the sustained high temperature and erosion from the flames and corrosive fuel ash slag of the coal fire within the furnace.

Historical accounts of cementation steelmaking in Sheffield mention that a type of refractory stone called 'ganister' was used to construct cementation furnace chests (Barraclough 1984, appendices etc), and the archaeological evidence from several furnaces in Sheffield confirms that this type of stone was used.

Ganister is a type of dense carbonaceous sandstone, and it is one of the most refractory natural stones available; substantial deposits of ganister were found under the coal measures in the Sheffield area. The melting point of ganister exceeds 1600°C (Havard 1912, 33), so it was entirely capable of resisting the 1100°C operating temperature of cementation furnaces.

From a cementation steelmakers perspective, the main problem with ganister was its tendency to expand and contract considerably when heated and cooled, and Havard (1912, 33) mentions how it would split and crack unless heated very carefully and gradually. The particular way that cementation furnaces were built (with transverse stone 'sleepers' and flue voids underneath the base and to the sides of the chests) meant that it would be difficult to prevent localised heating of the stone slabs of the chests.

What makes the Hollis Croft furnace unusual is that it is the first time archaeologists have excavated a furnace in Sheffield where parts of the side walls of the cementation chest are still standing. The presumption that the clay/slag-like substance was used to line the sides of the chests as well as the base has been confirmed. The excavation at Hollis Croft is also the first time that a longitudinal section of the base of furnace chests has been seen. The latter has revealed that the base of the chests are made up from several rectangular slabs generally 0.22m across, rather than two or three larger slabs. The use of smaller slabs would have created more joints, which would have the potential to allow air into the chests during firing.

Another unusual feature of the furnace chests at Hollis Croft are the faint longitudinal grooves and ridges on the surface of the slag-like layer in the base of the furnace chests. The grooves between the ridges are the same width as the type of iron bars that were normally converted in cementation furnaces, so it seems likely that the contents of the chest had sunk into the slag-like layer, either during loading or possibly whilst the furnace was being fired. To the author's knowledge, the ridges are not something that has previously been seen in furnaces excavated in Sheffield.

The author's previous qualitative analyses of samples of the slag-like layer from other cementation furnaces in Sheffield suggest that the raw material used to create the layer was a specific by-product of the cutlery and edge tool grinding trade in Sheffield. The by-product was known as wheelswarf, and it consisted of particles of finely ground stone and metal filings that accumulated as a sludge in and around the troughs that partially enclosed the water-cooled grinding wheels. The wheelswarf would have to be periodically cleaned out of the grinding troughs to allow new grindstones to be fitted, and this is presumably when it was sold or given away to cementation steelmakers.

Wheelswarf was used by Sheffield's cementation steelmakers to seal the tops of the chests in the cementation furnaces (Barraclough 1984, 42). A layer of around 100–125mm thick would have been applied to the top of the fully loaded furnace chests immediately before firing. During firing the layer would fuse together to form an impervious crust on the top of the chests. After the firing the fused crust (known in Sheffield as 'crozzle') would be broken up and taken out of the furnace, so that the converted bars of steel could be removed from the chests. Crozzle has a distinctive texture and an unusual jagged and abrasive fracture surface, and larger pieces were used in the Sheffield and South Yorkshire area as an intruder deterrent for the tops of walls. It would seem reasonable to assume that wheelswarf was also used to seal the base of the inside of cementation chests, however, the slag-like residue found in the base of furnace chests has a very different morphology and fracture surface to crozzle. Scientific analysis has been carried out to confirm whether the crozzle and chest residues are made from the same raw materials.

As mentioned above, the author's previous analyses of the residues from the chests of other cementation furnace excavated in Sheffield revealed that the slag-like residues found in the chests was not a slag by-product of the process. The results of the exploratory chemical analyses of chest residues and crozzle suggested that although very different macroscopically, the two residues could be related. The author has suggested that the steelmakers were deliberately adding the material to help keep the chest airtight during firing (Elmet Archaeological Services 2014).

The approach taken to the analysis of the furnace residues from Hollis Croft has been to have an independent analysis performed using techniques that complement one another; the latter will allow some comparison to be made with the results of previous qualitative analyses. The independent analysis has been carried out by Dr Patrick Quinn at University College London, and the full report on the analysis is shown below in Appendix 6 of the archive report [PDF].

Samples of the residue from the bases of the chests from each furnace at Hollis Croft, as well as a sample of crozzle donated by a collector were selected for analysis (Figure 64).

The material characterisation carried out by Dr Quinn has revealed that the slag-like residue found in the bases of the furnace chests could perhaps be more accurately described as a form of vitrified clay, rather than a slag-like material. The analysis has also confirmed that the vitrified clay layer in the chests is highly likely to be made from wheelswarf.

Some of the differences between the chest residue and crozzle samples mentioned in the analysis report could, in part, be attributed to the way that the wheelswarf was applied, and conditions that it was exposed to during firing. However, the inherently variable nature of wheelswarf itself, together with the potentially numerous sources of it, mean that some compositional variation between samples from the chests of different furnaces and crozzle are perhaps to be expected.

One of the most interesting findings of the latest analysis has been the variations in composition of different layers through the depth of one of the samples of chest residue (sample 1515). This finding corresponds with what the author has observed in some samples of chest residues from other furnaces, which has led him to postulate whether the relatively thick layer of residues found in the base of some furnace chests had built up through the successive application of fresh layers of wheelswarf when the first signs of cracks appeared in the surface of the previous layer of residue. The findings of Dr Quinn's report appear to suggest that this may have been a practice that was being carried out in one of the furnace chests at Hollis Croft.

Apart from the metalwork discussed above which relates to metalworking or other industrial processes, there are three other metal objects: two coins (one silver, one copper alloy) and a copper alloy button.

The silver coin is a long cross penny, identifiable on its high silver content as an issue of Edward I (1272–1307), under the new coinage issued from 1279 (see https://www.wessexarch.co.uk/news/hollis-croft-sheffield-cock-public-house-and-mystery-medieval-coin). It was found in 19th-/20th-century made ground 1007 associated with The Cock public house. (Trench B) The second coin, from a levelling layer (1234) associated with the 19th-century public house The Orange Branch (Area K), is a penny, illegible but probably no earlier than 19th century. The button came from a demolition layer (2140, Area E/F); it is a disc type with rear loop attachment, dating to the 18th century or later.

This report is based on examination of the leather on 23/05/2019. The leather was wet and washed when examined and stored in water in plastic bags within airtight plastic containers. The leather was recorded and a catalogue of the material for archive purposes is given in Appendix 7 of the archive report [PDF]. All relevant measurements and leather species identification are included. All measurements are in millimetres (mm). No shoe sizing has been calculated as no complete insoles have survived.

Leather species were identified by hair follicle pattern using low powered magnification. Where the grain surface of the leather was heavily worn or obscured identification was not always possible. The grain pattern of sheep and goat skins are difficult to distinguish and have been grouped together when the distinction could not be made. The term 'kidskin' has been used for particularly thin, fine-grained examples. Similarly, the term 'bovine' has been used when any uncertainly arose between mature cattle hide and immature calfskin. Shoe bottom components and repairs are assumed to be of cattle hide unless stated otherwise. The term 'shoe' has been used as a generic term to describe any item of footwear and may include boots. As the shoes are in poor condition and were found in modern contexts or unstratified, none were recommended for conservation.

At least seven individual items of footwear are represented by the leather examined from Hollis Croft, Sheffield. All are of metal riveted shoe construction; none are complete or near complete and so are difficult to date with accuracy, but front lacing boots and shoes can be recognised. On the remaining evidence they are likely to date to the end of the 19th and the beginning of the 20th century. Adult and child sizes are present, and they appear to be the result of domestic rubbish disposal.

Area B: The remains of five shoes (1-9), all of brass riveted construction, were found unstratified (1014) during evaluation of Area B. The shoes were recovered from the south-west corner in an area of small brick-built rooms. The shoes, two (3, 5) of a size to fit a young child, are in poor condition. Only one (2), a shoe of Oxford style of adult size, front lacing through five pairs of lace holes with metal eyelets, is sufficiently well preserved for the shoe style to be known. The five lace holes present suggest this Oxford shoe dates from the 1870s onward (Swann 1982, 49); the Oxford style remains popular today. Another shoe (1) from the same context has a relatively long pointed toe and more modern tread shape suggesting it dates to the 20th century.

Area E/F: The highly fragmentary remains of a shoe of riveted construction of adult size (11) were found in a modern drain (2052) in Area E/F. The construction of the shoe suggests the shoe dates no earlier than the second half of the 19th century (Swann 1982, 39). This construction continued to be used for lower-priced footwear throughout the first half of the 20th century (Salaman 1986, 156).

Area H: The left front opening broken from a front-lacing ankle boot (10) was found in modern rubble made ground, overlying archaeological deposits in Area H. The Balmoral boot, of suede calfskin, fastened up the leg through a series of nine lace holes and hooks. The boot style was popular throughout the second half of the 19th century and the first quarter of the 20th.

The assemblage comprises 181 fragments (1,835g) of animal bone, which includes 61 fragments of worked bone (industrial waste from handle manufacture). The assemblage includes material of late post-medieval to early modern date.

The assemblage was rapidly scanned and the following information quantified where applicable: species, skeletal element, preservation condition, fusion and tooth ageing data, butchery marks, metrical data, gnawing, burning, surface condition, pathology and non-metric traits. This information was directly recorded into a relational database and cross-referenced with relevant contextual information.

Bone preservation varies from good to extremely poor. The poorly preserved bones are highly fragmented and have flaky cortical surfaces making it difficult to distinguish surface details and identify elements to species. A few contexts include bones in different states of preservation and this is a general indication that material has been reworked and redeposited from earlier contexts. Gnaw marks were apparent on only four bones. This is a very low occurrence and suggests that the assemblage has not been significantly biased by the bone chewing habit of scavenging dogs.

Bone was recovered from Trenches/Areas A to D, F, and H to I, and includes material of domestic and industrial origin, the latter relates to bone- and antler-working associated with handle manufacture for the local cutlery industry (APS 2016).

Identified species in the domestic waste include butchered bones from cattle, sheep/goat and pig. Cuts of mutton appear to have been the most commonly consumed source of meat, followed by beef and then pork. A few rabbit bones were also identified and these undoubted provided a welcome cheap addition to the diet of those working in the area.

Sixty-one fragments of worked bone were recovered, all falling within the category of industrial waste, comprising waste and finished objects from handle manufacture (Table 4). The main concentration of this industrial waste came from Trench A, specifically pit 904, and layers 902 and 915. These deposits include the typical waste from successive stages of handle manufacture: sawn ends from cattle metapodials, and the rectangular blanks and off-cuts from the shafts of these bones, as well as finished parts of scale handles, some of which are decorated (scored lines and cross-hatching; Plate 74, Plate 75). Sawn fragments of fallow deer antler also came from pit 904 and at least two of the handles from layer 916 appear to have been fashioned from antler rather than bone. An off-cut from bone-working was also recovered from layer 1637 in Trench C. Deer antler handles were also recovered from layer 1122 in structure 1118, Trench I, and unstratified layer 1635 in Trench C.

| Trench/Area | Context | Object Type | Species | Element | No. | Description |

|---|---|---|---|---|---|---|

| A | 902 | Off-cut | Cattle | Metapodial | 3 | Small sawn off-cuts (from long bone shafts) from handle manufacture, two copper stained |

| A | 902 | Handle | Cattle | ? | 1 | Pistol-grip scale knife handle broken at one end (surviving length 59mm); one rivet hole at end; slight copper staining |

| A | 905 | Off-cut | Cattle | Metapodial | 3 | Sawn proximal and distal ends from cattle metapodials |

| A | 905 | Off-cut | Cattle | Metapodial | 16 | Sawn off-cuts (from long bone shafts) from handle manufacture (some may be blanks), two with copper staining |

| A | 905 | Handle | Cattle | Metapodial | 5 | Scale knife handles, all probably from metapodial shafts (one preserves the foramen); two nearly complete (squared butts), the others partial; three decorated with incised cross-hatching (1 with 3 rivet holes along length), one with incised chevron bands, one with simple longitudinal lines |

| A | 905 | Off-cut | Fallow deer | Antler | 8 | Sawn antler off-cuts, 3 possibly from crown, one other tine end could come from another tine; all could belong to single antler set |

| A | 916 | Off-cut | Cattle | Metapodial | 17 | Sawn off-cuts (some may be blanks) from long bone shafts |

| A | 916 | Off-cut | Cattle | Metapodial | 1 | Sawn across just below distal end |

| I | 1122 | Handle | Deer | Antler | 1 | Pistol-grip scale knife handle (probably from pocket knife), complete (length 73mm); 3 large and 2 small rivet holes |

| C | 1635 (unstratified) | Handle | Deer | Antler | 1 | Scale knife handle fragment, broken across 2 rivet holes; decorated with diagonal hatching with oblique incisions across the diagonal bands |

| C | 1637 | Off-cut | ? | ? | 5 | Thin sheet fragments, all probably conjoining (largest 31 x 15mm, thickness 2mm); uncertain function; species unidentified |

The unworked marine shell (79 fragments) includes oyster, mussel and cockle (Table 5). For the oyster, both right and left valves are represented in roughly equal proportions, i.e. both preparation and consumption waste. Just over half (57%) preserve original measurable dimensions.

There is also one piece of worked shell in the form of a mother-of-pearl button, with an incised rosette motif around the central perforation. This came from demolition layer 902 in Trench A.

| Tr / area | Context | Count | Species | Additional Comments |

|---|---|---|---|---|

| A | 902 | 2 | oyster | 1 R, 1 L valve |

| A | 902 | 1 | oyster | Obj No 1: mother-of-pearl button with incised rosette motif |

| A | 916 | 2 | oyster | fragments |

| A | 916 | 2 | mussel | fragments |

| I | 1113 | 1 | mussel | |

| D | 1704 | 66 | oyster | 32 R valve (23 measurable), 35 L valve (17 measurable) + frags |

| E | 1816 | 1 | mussel | |

| E/F | 2011 | 1 | cockle | |

| E/F | 2115 | 4 | oyster | 1 R valve, + frags |

View the comic online or use the navigation bar (top) to go to other sections of report.

Internet Archaeology is an open access journal based in the Department of Archaeology, University of York. Except where otherwise noted, content from this work may be used under the terms of the Creative Commons Attribution 3.0 (CC BY) Unported licence, which permits unrestricted use, distribution, and reproduction in any medium, provided that attribution to the author(s), the title of the work, the Internet Archaeology journal and the relevant URL/DOI are given.

Terms and Conditions | Legal Statements | Privacy Policy | Cookies Policy | Citing Internet Archaeology

Internet Archaeology content is preserved for the long term with the Archaeology Data Service. Help sustain and support open access publication by donating to our Open Access Archaeology Fund.