Many items in the household would have been made from organic materials, and the inventory must therefore be presumed to be very incomplete (Table 61).

The most common type of artefact relating to food preparation was the quern. The large number is a reflection of the importance of bread in the inhabitants' diet. Other objects concerned with food preparation are scarce, apart from ceramic mortaria, the standard Roman mixing bowl. A number of the larger knives were probably used in butchery and food preparation, though there are no complete cleavers or choppers. The evidence for meat preparation is complemented by the presence of butchery marks and collections of butchery waste among the animal bone assemblage. Preservation of meat by salting is obliquely suggested by the large assemblage of salt briquetage. A number of fragments from ceramic cheese-presses were found, and salt would also have been used in cheese-making. Cooking processes are represented by a number of metal vessels and their fittings, and utensils used in cooking, some of which will be mentioned in more detail below. The main cooking styles that can be identified are boiling and frying.

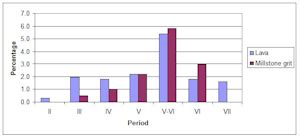

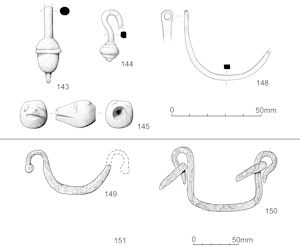

Knives are the most common iron finds from Roman sites after nails, and most would have been multi-purpose tools, used for preparing food and eating, as well as in everyday life in general. Flesh-hooks with two or more curved prongs would be used to serve meat from the cauldron or cooking pot, and there is also a possible iron ladle bowl from the site. Seven spoons were found, including one outstanding copper-alloy spoon, with a zoomorphic head on the handle, and part of what must be a matching spoon, both unstratified.

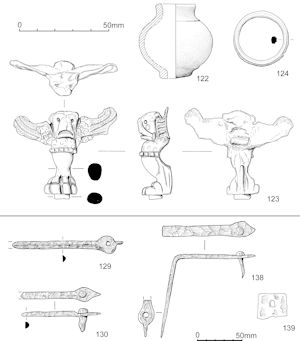

There was a fairly large assemblage of metal vessels from the site, including a hoard of five pewter vessels, and a complete copper-alloy jug (these were deliberately deposited); shale vessels were also well represented. Glass and ceramic vessels are considered elsewhere. The group included one definite fragment of a pre-Roman copper-alloy vessel, a cast, vine leaf-shaped escutcheon, probably from a large bowl. It is very similar to a pair of escutcheons from the Lexden tumulus (Foster 1986a, 63, nos 6 and 7), which were probably deposited c. 15-10 BC.

The finds from Elms Farm provide little information on what the furnishings of the houses would have looked like, either in the Late Iron Age or the Roman period. Most of the furniture would have been based on organic materials, which have not survived. An eroded, circular slab of Purbeck Marble, from a Late Roman context, may have been a table top (or perhaps a table top that was subsequently made into a quern). Other possible furniture fragments are an iron bar, which may be a brazier or tripod leg, and a mount, in the form of a lion foot surmounted by a winged lion's head; this may have been part of the leg of an object such as a tripod, or casket or possibly a vessel foot. A large hollow knob may have been an element from a piece of furniture, such as the leg of a couch. Some of the numerous iron nails recovered may also have been used in furniture construction.

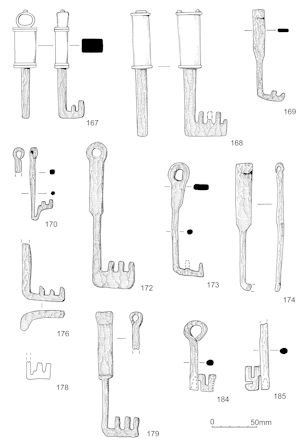

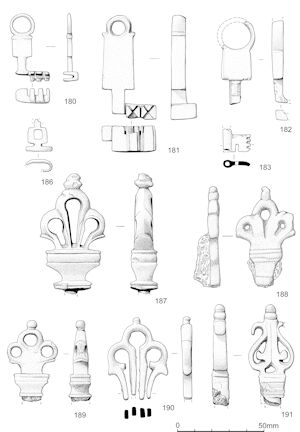

The use of chests and boxes for storage is clearly indicated by the number of box fittings found, items such as box-rings, drop handles, decorative studs of types frequently found on boxes, and angle brackets. Chests appear to have been made on site, at least during the Early Roman period, since many of the ceramic metalworking moulds found are probably for casting box-rings, which often had distinctive circumferential ribbing at that time. Many of the keys found would have belonged to chests rather than doors. The number of keys from the settlement suggests that security was an important consideration; not only the security of the house as a whole, but the ability to secure items of value within a locked chest or cupboard. This may have been particularly relevant for the temple complex, where, no doubt, there was a considerable amount of relatively valuable material stored.

In common with most rural sites, the evidence for artificial lighting is sparse, consisting of a few fragments of ceramic lamps, lead candlesticks, two possible pieces of pottery candlesticks, and an iron hanging lamp. It has to be assumed that most lighting was in the form of torches or rush-lights that have left no archaeological trace.

Eight spoons were found, five made from copper alloy, two from iron, and one from bone. In addition, the iron object described below as a small hemispherical bowl (no. 62) could be a ladle bowl.

1. Handle from a spoon with a mandolin-shaped bowl, broken across the top of the bowl. The handle is curved, with a well-modelled zoomorphic head part-way up, and a bifurcated knobbed terminal, partly missing. The rest of the handle may have folded, but there is no indication of a pivot, or any other way of attaching the rest of the handle. The more normal notched crook at the end of the handle is transformed into a perforation, a feature found on a few other spoons, and probably a late feature. One of the few other examples with a perforated crook is a 4th-century spoon from Frocester (Price 2000, 53, no. 317). L. 68mm. SF3000, Machining layer 11000, Area A, unstratified

This is, quite literally, a 'table spoon', since the shape of the handle copies that of a curved table leg, complete with foot and animal head. The mouth is open, suggesting that the head is that of a panther, generally shown as snarling on table legs; Liversidge (1955, 42) illustrates a similar beast adorning a marble table leg from Pompeii. There is an exactly similar parallel for this spoon from the fort at Piercebridge, now in the Bowes Museum (a photograph of the spoon appears on their website). Decorated spoon handles are quite rare in Britain, and generally bear incised geometric motifs. Handles with moulded motifs are rarer. They include an undated spoon from Lydney, which also has a perforation instead of a notch at the end of the handle, which has a stylised hare at the bowl end; a late date was postulated, as the conventionalised form was seen as a 'Teutonising tendency' (Wheeler and Wheeler 1932, 85, no. 91). A folding spoon from Traprain Law similarly has the animal (a lion?) moulded at the bowl end, in this case the pivot for the handle lying between the paws (Robertson 1970, 217).

2. Bowl from a spoon with a mandolin-shaped bowl, broken across the beginning of the handle. The surviving part of the handle is virtually identical to SF3000, suggesting that they were a pair. The perforated crook is so rare a feature that they must at least have come from the same factory. L. 52mm, W. 26mm. SF3001, Machining layer 11000, Area A, unstratified

3. Not illustrated. Spoon bowl, circular, with white metal coating. There is a scar on the edge where the handle has detached. In good condition, with some concretion on the surface. This is Crummy's type 1, dated to the second half of the 1st century to the 2nd century. Diam. 25mm. SF2273, Fill 5546, Post-hole 5547, Group Area J, Period 4

4. Not illustrated. Spoon handle, probably from a small spoon. The handle is offset, with the end probably pointed, but not definitely complete. It is in very poor condition, and the details are unclear. There appears to be a low moulding round the inner edge of the curve of the handle, an apparently rare feature. L. 54mm. SF3292, Fill 9475, Ditch 9476, Area D, Period 3B-4

5. Not illustrated. Three joining fragments from a small spoon handle with white metal coating, Crummy type 2 or 3 (1983, 69), with an offset handle. The types are both first half of the 1st century onwards. L. 45mm. SF860, Cleaning layer 6000, Area H, not phased

6. Not illustrated. Incomplete spoon handle, made from a twisted bar, with a small part of the bowl. Similar to Manning 1985a, 104, P34. Surviving L. of handle 50mm, bowl W. >50mm. SF8128, Context 3999, Spoil-heap

7. Not illustrated. Part of a shallow oval spoon bowl. The object is very mineralised, and the X-ray very faint, but the complete width appears to be present. W. c. 52mm, surviving L. 70mm. SF6197, Fill 15152, Pit 15229, Group 699, Area M, Period 5

The bone spoon (Figure 455.8) is of a type that is also made in copper alloy, and is an early form, dating to the mid-1st to 2nd century (Crummy 1992c, 215). The Elms Farm spoon was found in a late Roman pit, and is presumably residual. Crummy (1983, 69) states that Martial (Epigrams 16, 121) describes these spoons as being used to eat eggs, with the pointed handle serving to extract shellfish from their shells.

8. A well-made spoon with a rounded bowl, Crummy type 1. Handle tip broken off. SF6654, Fill 15549, Pit 15738, Group 698, Area M, Period 5

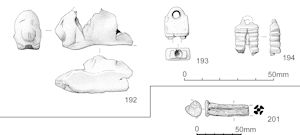

9. Fragment from the tip of a flesh hook. The prongs are short and straight, and the section of the bar is an irregular quadrilateral. Most flesh hooks have longer, curving prongs (as on the other illustrated example from Elms Farm), although the short, straight prongs are paralleled on a flesh hook from Stonea (Jackson and Potter 1996, 364, no. 27). L. 49mm, prong L. 9mm, section 10x8.5mm. SF2105, Fill 2105, Pit 2132, Group 889, Area W, Period 3 (Figure 455)

10. Not illustrated. Flesh hook, handle incomplete. There are two prongs, one probably complete, with the tips only slightly bent. The handle is broken at the start of a twisted section. L. 175mm, prong L. 25mm. SF6265, Fill 14759, Pit 14758, Group 711, Period 4

11. Not illustrated. Possible flesh hook fragment. A square-sectioned rod, with a fresh break at one end and an old break at the other. It has a curved rod welded on, very little of which survives, which may have been one of the pair of prongs of a flesh hook. L. 52mm, W. 5mm. Fill 11139, Pit 10910, Group 676, Period 5

12. Flesh hook, with two curved prongs. The square-sectioned bar was probably broken in antiquity, and has no twisted element surviving. L. 134mm, L. of prongs 30mm. SF6276, Cleaning layer 20000, Area L, not phased

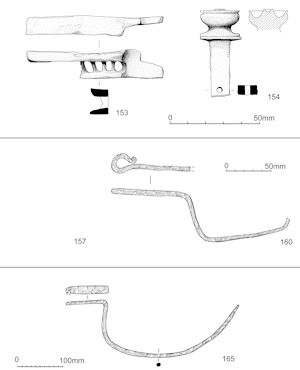

Two lead tripod candlesticks are catalogued below; the leg of a third candlestick was found during machining, but was lost prior to cataloguing. The candlesticks are of a form first noted by Major and Eddy (1986), who, however, failed to identify their function. A complete and undistorted example from Colchester Royal Grammar School (in Colchester Museum) was subsequently identified by Paul Barford as a candlestick. It is now considered by the present writer that the objects are unlikely to be of Christian significance, given the range of decorative motifs present. Major and Eddy identified two groups of decoration, and both Heybridge examples belong to Group A. This is the most numerous group, with seven examples known to the present writer. There are two from Woodcock Hall, Norfolk (R. Brown, pers. comm.), one from Canterbury (P. Garrard, pers. comm.), one from Kelvedon (Major and Eddy 1986), one from Balkerne St, Colchester (Crummy 1983, 168), and the two from Heybridge.

Four further examples identified since 1986 do not belong to either decoration group. Two are from Colchester (the Royal Grammar School candlestick, and one from Culver Street; Crummy 1992a, 163), and are broadly similar, with a pattern of lozenges and lines, together with large dots in the case of the Culver Street candlestick. There are also two from Piercebridge (L. Allason-Jones, pers. comm.), which appear from the descriptions to be a different group again, though utilising patterns of lines and hanging scallops in a similar way to Group B.

Unlike some of the other examples, the Heybridge candlesticks are not well moulded, with poorly moulded vertical lines, and a rather flattened area in the middle. While not exactly similar, certain features suggest that the two candlesticks came from copies of the same mould; in particular, both have a dot straddling the line toward the top left corner as drawn, and both have a very similar blob at the bottom left. None of the other candlesticks in the group was definitely made from this mould, though two other pairs can be distinguished. The candlesticks from Balkerne St, Colchester, and Kelvedon both have a dot at the base of the vertical line, and dots overlying the slightly thickened top, while the Canterbury candlestick and one of the examples from Woodcock Hall both have a central dot, and similar dots overlying the oblique line in the bottom right-hand corner.

The differences between the members of Group A are fairly minor, and they could be the product of a single workshop. Indeed, despite the differences in decoration, all the lead candlesticks could be from the same workshop. The majority of the examples are from East Anglia, with an apparent concentration in Essex, so a source fairly local to Heybridge can be surmised. It is tempting to suggest that Elms Farm, with its copious amounts of waste and scrap lead, was the location of the candlestick workshop, but there is no evidence for the lead having been used to make any particular product. The candlesticks could even be present on the site merely as scrap lead for recycling.

Both Heybridge candlesticks were from undated contexts, adding nothing to the dating for the type, which on evidence from elsewhere is 2nd-3rd century AD.

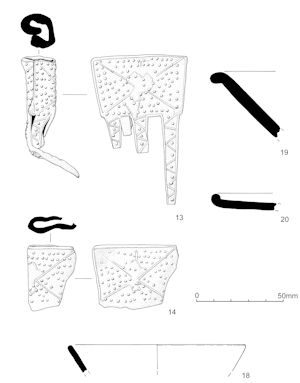

13. Candlestick, made from a cast sheet rolled into a cylinder. The three legs could then be spread to form a tripod, and the short, undecorated tab bent to form the base of the cylinder. The surface is decorated with raised dots and lines. Only one of the legs survives to its full length, with the other two broken off just below the socket. SF833, Machining layer 4000, Area A1

14. Part of the socket of a candlestick with decoration similar to the previous example. The surface is damaged in the top left-hand corner as drawn, and the dots have been obscured. SF4806, Cleaning layer 12207, Area R

Cite this as: Crummy, N. 2015, The ceramic lamps, in M. Atkinson and S.J. Preston Heybridge: A Late Iron Age and Roman Settlement, Excavations at Elms Farm 1993-5, Internet Archaeology 40. http://dx.doi.org/10.11141/ia.40.1.crummy2

This tiny assemblage contains one picture lamp, one open lamp, and one factory lamp. Picture and open lamps were first imported by the invading Roman army, mostly from Gaulish factories, a few from Italian. They are only found in any great number on sites with a military or very 'Roman' civilian character, and are not common on native settlements. A factory copying continental products was established some time before AD 60 at Colchester, but destroyed in the Boudiccan revolt (Dunnett 1971, 35, 37 note 3; Crummy 1983, 77). Factory lamps (Firmalampen), also mostly from Gaul, replaced picture lamps in the second half of the 1st century, and were again copied in Britain. The production sites of Colchester and London are the closest to Elms Farm (Hull 1963, 109-10; Marsh 1978, 192).

The picture lamp fragment belongs to the middle or second half of the 1st century AD and may be of Gaulish manufacture, though the fabric is very soft and the shoulder form is debased, suggesting a British product rather than an import. The other two Elms Farm lamps are in a mica-dusted fabric made in London and date to the end of the 1st century or the first decades of the 2nd.

The low number of pieces present suggests that the use of lamps for artificial lighting was not common on the site, and was restricted to a very limited number of people. The long time-span involved further emphasises the minimal effect that this aspect of Roman life had on the settlement.

15. Two joining wall/shoulder/discus abraded fragments of a picture lamp in an fine oxidised fabric. Only a small part of the discus with a shallow concentric groove remains. Diameter approximately 58mm. Insufficient remains to identify the form with certainty, but the shoulder profile suggests that this may be a debased Loeschcke Type IV, V, or VIII (1919, Taf. 1). Probably Gaulish and dating to the second half of the 1st century. SF7706, Fill 10649, Post-hole 10648, Group 827, Area F, Period 4

16. Fragment of an open lamp in a hard fine mica-dusted redware with well-defined grey core. The front part of the lamp narrows towards a nozzle. The inside of the base is slightly raised. Though mould-pressed, part of the rim was brought level with the rest by being pinched and pulled upwards between the fingers. Diameter approximately 65mm. A London product of the late 1st century or early/mid-2nd, similar to an example in the British Museum (Bailey 1988, pl. 8). Fill 15151, Pit 15229, Group 699, Area M, Period 5

17. Two joining abraded fragments of a factory lamp in a fairly fine orange fabric with traces of mica-dusting, probably applied as a slip but now largely worn off. There are traces of burnt deposits at the nozzle. There is a shoulder lug near the back of the vessel. Surviving length 58mm. Loeschcke Type X, with open nozzle channel (1919, Taf. 1), almost certainly made in London. The shoulder lug is in a similar position to those on a mould for a factory lamp from the city (Marsh 1978, fig. 6.24, 62.3), and on a complete lamp from New Fresh Wharf (Richardson 1986, 132-3, no. 1.224). Late 1st or early/mid-2nd century. SF2394, Fill 7301, Pit 7302, Group 883, Area G, Period 4-5

Cite this as: Tyrrell, R. and Major, H. 2015, Shale vessels, in M. Atkinson and S.J. Preston Heybridge: A Late Iron Age and Roman Settlement, Excavations at Elms Farm 1993-5, Internet Archaeology 40. http://dx.doi.org/10.11141/ia.40.1.major8

N.B. The ceramic and glass vessels are reported upon elsewhere.

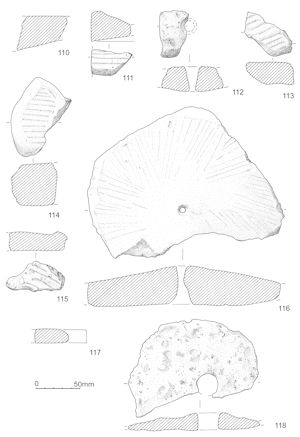

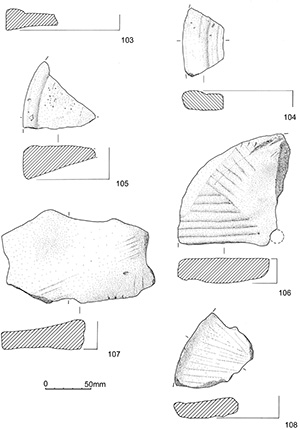

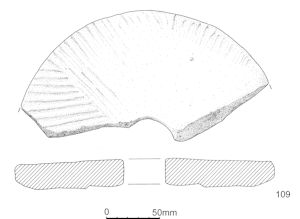

None of the vessel fragments was very large, and their condition tended to be poor. Owing to their resemblance to pottery, they were often not recognised as shale by the excavator, and had dried out by the time they were identified. Although the source of the shale was not identified petrologically, it is likely that it is Kimmeridge shale, and that it was brought to the site as finished objects.

Although there are fragments from only ten or eleven vessels, this is an unusually large assemblage for this part of the country. Crummy (1983, 71), for example, notes only five vessel fragments from the Colchester excavations, together with parts of three trays. Most of the vessel fragments are from early to mid-Roman contexts, with only one fragment from a later Roman context. A single body sherd is from a possible Late Iron Age context (post-hole 9140, Area D). Although shale artefacts were in widespread use at this time, there are very few Iron Age finds from Essex. The only assemblage of any size is from a Late Iron Age enclosure at Stansted Airport (Major 2004a, 137), which produced eight fragments, all from vessels.

There is also a sherd with a straight edge (SF7284) which may be part of a palette, a plaque, or a piece of inlay. Most shale palettes have bevelled edges, but this one has a quarter-rounded edge, so it is perhaps more likely to be a plaque or inlay.

The distribution is strongly concentrated in Area H, with eight of the fragments coming from the area. Three of these were platter rims of very similar form, from Ditch 6358, Pit 6873 and Pit 6149 (Periods 4 and 5). They could possibly be parts of the same platter, as the low kerbs round the edge are the same width on all of them. In particular, the fragments from the two pits could be the same vessel, as the pits are c. 1m apart. The find spot in the ditch is approximately 15m from the pits. Even if they are from different platters, it seems likely that they were part of the same consignment of vessels. The form of the edge is very unusual; most platters have beaded edges, as does the other platter fragment from Elms Farm (SF2874). None of the fragments has a footring surviving, so there is a possibility that they are something other than platters. However, there is slight dishing evident, which would rule out use as a tray, and the diameter seems too small for a tabletop.

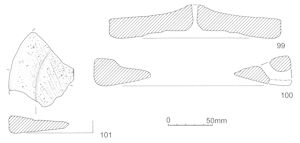

18. Plain cup or beaker rim. L. 44mm, W. 14mm, T. 3mm, estimated internal diam. 80mm. SF7207, Fill 13721, Pit 13824, Group 594, Area I, Period 3A (Figure 456)

19. Shallow dish with a plain bead rim. L. 50mm, T. 7mm, estimated internal diam. 260mm. SF2874, Layer 6227, Group 573, Area H, Period 5-6

20. Shallow dish with a plain bead rim. L. 51mm, T. 5mm, estimated internal diam: 240mm. SF2647, Machining layer 11000

21. Shallow dish with the rim damaged. L. 62mm; W. 54mm; T. 5mm; estimated internal diam: 200mm. SF4679, Fill 6355, Ditch 6358, Group 564, Area H, Period 4-5

22. Shallow dish, with a rim in the form of a slightly thickened edge. L. 70mm; W 45mm; T. 5mm; estimated internal diam: 180mm. SF7723, Fill 6150, Pit 6149, Group 577, Area H, Period 4

23. Three flat body sherds, laminated. Two join, forming probably the complete thickness of a straight-sided object, either a palette or a tray. It is more likely to be the former, as it is only 8.5mm thick. The edge is rounded on one face only. 29x58mm. The third piece is badly laminated, and is probably from a different object. It is uncertain whether the full thickness is present. Approx. dimensions 60x32mm, Th. 10mm. SF7284, Cleaning layer 6552, Area H

24. Flat body sherd. L. 41mm; W 33mm; T. 10mm. SF5403, Fill 4692, Slot 4695, Group 1161, Area K, not phased

25. Flat body sherd. L. 41mm; W 30mm; T. 6mm. SF8418, Layer 6316, Group 547, Area H, Period 4

26. Flat body sherd. L. 66mm; W. 40mm; T. 5.5mm. SF5127, Fill 6351, Well 6280, Group 531, Area H, Period 3-4

27. Flat body sherd. L. 52mm; W. 59mm; T. 6mm. SF7457, Fill 6874, Pit 6873, Group 546, Area H, Period 4

28. Flat body sherd. L. 60mm; T. 12mm. SF5745, Post-hole 9140, Group 2116, Area D, Period 2-3

Cite this as: Crummy, N. 2015, The pewter hoard, in M. Atkinson and S.J. Preston Heybridge: A Late Iron Age and Roman Settlement, Excavations at Elms Farm 1993-5, Internet Archaeology 40. http://dx.doi.org/10.11141/ia.40.1.crummy4

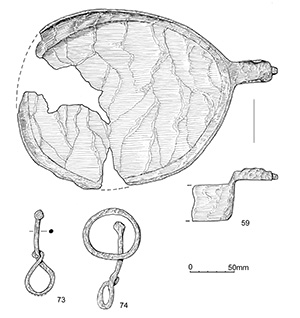

The hoard was found in the bottom layer of F6641, (Group 579), a large Period 5 pit in Area H, and consists of five nested cast vessels, two plates and three hemispherical pedestalled bowls or dishes. The only other metalwork from the pit was a small scrap of lead, but the same context contained the articulated remains of a decapitated horse and was sealed by some 14kg of tile mixed with fragments of stone.

The pedestal bases for the bowls were made separately and attached to the main sections with solder. The visually disparate quality of the metal between the two pieces was confirmed by X-ray fluorescence spectrometry at the former Ancient Monuments Laboratory, now within English Heritage Intervention and Analysis. Both the plates and the pedestal bases of all three bowls were found to be made from a tin-lead alloy at a ratio of 50:50. The main parts of the bowls were closer to a ratio of 75:20, tin to lead (A. Sutherland, AML Report, unnumbered). This difference is close to that found in the analysis of the two-piece bowls in the Appleford, Berkshire, hoard (Brown 1974, catalogue nos 7, 11), where the bodies had ratios of about 81:19 and 77:23 tin to lead respectively , while the separately made base of bowl 7 and footring of bowl 11 were 38:62 and 42:58 respectively (A.M. Pollard 1983; Beagrie 1989, 174). The consistency in this variation clearly produced benefits to the maker, one of which may have been a greater degree of malleability if the product required further shaping after casting.

All the Elms Farm vessels were finished on a lathe. All have the marks of attachment to the lathe centre in the middle of the inner face, and all have the regular striations on the inner and outer faces made by polishing. The only areas left unpolished are those within the footrings of the plates, which would have been covered by the lathe face-plate, and the insides of the three pedestal bases on the bowls, each of which is rough with the solder smeared on when it was attached to the dish.

Brown notes that a central nail or spike and three outer spikes were set into a lathe face-plate to grip the vessel being turned (1974, 187). Both of the Elms Farm plates have a central plugged nail-hole, but, rather than indentations from three spikes, SF4323 has three flattened areas on the footring set equidistantly, probably smoothed patches from filling spike holes, and SF4322 also three patches but they are of different length and not set equidistantly. They probably also represent filled spike holes, but, as the footring has suffered considerable damage, one or more them may be later repairs. Only the largest bowl, SF3421, appears to have been pierced by a face-plate nail. The lathe-centre mark on SF3420 has scarcely left any mark at all on the inner face, while the smallest bowl, SF3419, has a depression with raised rim from a lathe-centre on the inner face, and a prominent bulge on the underside where the metal has been forced outwards. A similar bulge was noted on a pedestalled cup from Hockwold cum Wilton (Gurney 1986, fig. 92, 1).

The two plates are of similar size but different form. One has more-or-less vertical sides with only a very slight turned-out rim, the other has rather more sloping sides and a well-defined everted rim. Neither profile is represented in Peal's classification (1967). Both have slight footrings cast in one with the vessel, though with secondary damage/patching as described above. The three bowls are graded in size, at 132mm, 154mm, and 194mm. Though in detail the three are quite different, in general form they are united in being hemispherical, with wide rims, and having a base made separately and soldered on. The rim of the largest has a beaded edge that has been grooved at regular intervals, the medium-sized one has cast dots set regularly around the flat raised rim, while the smallest is plain.

Each plate has concentric decoration on the inner surface. On SF4322 this takes the form of scribed lines, on SF4323 of shallow concave grooves inside a pair of scribed lines. There is no such decoration on the bowls.

The decorative techniques used on the rims of two of the dishes are paralleled elsewhere. For example, the cast dots of SF3420 occur on a dish found in the Sacred Spring in the temple of Sulis Minerva at Bath (Sunter and Brown 1988, fig. 5, 13) and on two bowls from Thatcham, Berkshire (Collingwood 1931, figs 6, 8-9). The grooved bead of SF3421 occurs on a fragment of a rim from the Sacred Spring (Sunter and Brown 1988, fig. 5, 16) and on the rim of a plate from Verulamium (Goodburn 1984, fig. 27, 242). Both techniques are presumably an attempt to imitate the truly beaded rim of silver vessels such as those in the Mildenhall hoard, where many of the plates and dishes have well-formed globular beads set around the rim and even, in the case of the goblets, around the foot. On the covered bowl in the same hoard the design has developed into a 'necklace' of alternating large and small beads (Painter 1977a, pls 1-30).

The undersides of each of the Elms Farm plates and the underside of the rim of the medium-sized bowl (SF3420) are scratched in places. Some of these lines were clearly made when the scribing tool used during finishing slipped, as they can be traced back to finely scored lines at the junction of rim and wall or footring and base. Others, such as the row of parallel lines set at right-angles to the footring on SF4323, are clearly deliberate graffiti. Two marks on SF3420 are graffiti which have been developed from accidental scratches. One is an X, with one cross-piece made accidentally, the other deliberately. The other is a Chi-Rho, with one cross-piece again accidental, the other and the Rho added. This symbol is particularly faint, and would not have been visible in the normal usage of the bowl. As the lines that were deliberately added appear to have been made by the same tool as the accidental scratches, they can be presumed to have been made by the maker. It is therefore likely that the purchaser, provided the vessel were ever sold, either did not realise the mark was there, or did not object to its presence.

In the same way that the three bowls in the Elms Farm hoard are similar in general shape but different in detail, the form of each of the five vessels can be matched, though not necessarily exactly, by examples in other large deposits, such as the Sacred Spring at Bath, and the hoards from, for example, Appleford, Berkshire, Hockwold cum Wilton, Norfolk, and the Fens (Sunter and Brown 1988; Brown 1974; Gurney 1986, 149-53; Lethbridge and O'Reilly 1933, 165-6; Liversidge 1959).

That most excavated pewter vessels derive from waterlogged deposits can largely be explained by the fact that the metal does not survive well in ordinary burial conditions. Pewter vessels as ordinary site finds or grave deposits are rare, though examples have been found at, for example, Baldock and Colchester (Johns 1986, 144; Crummy 1983, 72; Crummy et al. 1993, 24, fig. 2.8e).

The majority of pewter hoards, including that from Elms Farm, are dated by context to the Late Roman period, usually the 4th century, though the potential longevity of pewter vessels has been pointed out by Sunter and Brown (1988, 20). The individual items in a hoard may, therefore, pre-date its deposition by some decades, or centuries. Several pewter manufacturing sites dating to the 3rd and 4th centuries have been identified in Britain, the majority being scattered across the south, with a concentration around the lead-mining region of the Mendips, but some being at least as far north as Yorkshire and Northumberland (Beagrie 1989, 181-90, fig. 4). There is far less evidence for pewter manufacture in the Early Roman period, but Brown has pointed out the significance of the Walbrook finds from London when estimating the age of vessels in Late Roman hoards (Sunter and Brown 1988, 20).

There remains the question of whether or not this hoard of vessels was a religious deposit, or one hidden by the owner at a time of crisis with the intention of returning to retrieve it. Many hoards of metal vessels found in wells or other wet deposits have been interpreted as votive offerings (Poulton and Scott 1993), though this is rarely unequivocally supported by other evidence (Parkhouse 1997, 160-1). For example, three pewter vessels found in Late Roman mud beside the River Ver, with a large number of coins found scattered close by, were interpreted as offerings thrown into the river (Goodburn 1984, 65). While this is difficult to refute, it is also very far from proven.

One of the twenty-four vessels making up a hoard found in the bottom of a well at Appleford, Berkshire, was inscribed EMITA PARTA SVA LOVERNIANVS DONAVIT (Lovernianus presented the things he had bought), suggesting that this group was genuinely a votive deposit (Brown 1974, 193). However, Brown noted that this hoard, along with many others, is not composed of matching sets but of vessels acquired over many years, possibly 100 or more (Brown 1974, 201), thus an alternative interpretation might be that this is a scratched reminder of a gift of some items (not all necessarily vessels, nor all necessarily then deposited in the hoard) to a temple, or even possibly to a patron, associate, or relative. The hoard then becomes one intended to be retrieved.

One of the plates in the Elms Farm hoard (SF4322) has been deliberately bent, and the other (SF4323) is lacking part of its wall, damage that may have been exacerbated during deposition but almost certainly existed before the object was placed in the pit. Of the dishes, one is a poorly made piece (SF3419) and also has some degree of wear on the rim and base, as do the other two (SF3420-3421). That the only other metalwork found in the pit was a scrap of lead, that the Chi-Rho on bowl SF3420 was hidden and seemingly casually made rather than overt and done with care, and that the vessels were found neatly nested together and so may have been deposited in either an organic wrapper (perhaps a piece of textile or a leather bag) or in a jointed wooden box that has subsequently rotted away, are all strong indicators that this hoard was not votive, but belonged to a metalworker intending to recycle the pieces, but forced by circumstance to hide them in the hope of later recovery. The pit in which they were found was in the area of the market, and there is some evidence for lead-working nearby (see Period 5). This interpretation is supported by Johns' attempt to devise a classification for hoards, in which the characteristics of the Elms Farm hoard noted above appear to define it as that of a manufacturer (1996, esp. 14-15, type 5b).

However, if the evidence of the mutilated plate is put to one side, the vessel group, with two plates of similar size and three bowls graded from small to large, could be seen as a deliberately selected service, either personal or temple treasure. The structure of the group is therefore the best argument against the hoard being that of a metalworker. Add to this the presence of a decapitated horse in the same context and the careful sealing of the deposit with a layer of tile and stone fragments, and the likelihood that the burial of both horse and hoard was a ritual act becomes more likely.

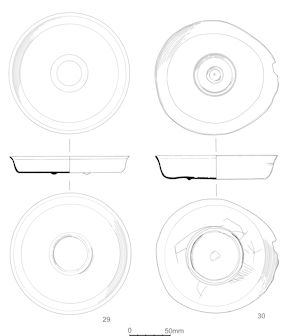

29. A small plate with sloping sides and slight everted rim . External diameter 141mm, height approximately 24mm. The inside is marked by two fine incised concentric circles around a plugged central face-plate spike-hole. The plug has been smoothed reasonably flat on this surface, but on the underside is still rough and prominent. Both the inner and outer surfaces of the plate have the concentric striations made by lathe-turning. The low footring is now very rough, but was triangular in profile originally. There are three flattened areas on it, at least two probably from filling in spike-holes left by the lathe face-plate. The third is long, and may also be from infilling a spike-hole, but could be a later repair. SF4322, Fill 6640, Pit 6641, Area H, Period 5

The plate has suffered considerable damage. While that on parts of the footring may be from use, much more is clearly deliberate. There is a deep linear indentation across one side of the plate, and the wall opposite has been pushed in slightly, as if there has been an attempt to fold the sides inwards. The surface of the indentation is not broken, suggesting it was not made by striking the plate. An object with a long hard edge was probably used to hold the plate down while the wall was lifted up and pushed inwards. Further damage consists of what may be hammer marks close to, and on either side of, the linear indentation, though a similar effect would probably be produced by banging the plate sharply against a pebble surface. (Figure 457)

30. A small plate with more-or-less upright walls and very slightly everted rim. External diameter 137.5mm, height 28.5mm. The surfaces have the horizontal striations made by lathe-finishing. There are concentric grooves around a central plugged hole on the inner surface. The plug has been smoothed on the upper side, but is quite prominent, though neatly smoothed, on the underside. The low footring is integral to the moulding. It is flattened in three equidistant places, possibly by raised areas on the face-plate of the lathe. There are several scratches made with a fine scribing tool around the outside of the footring. Some are caused when the tool slipped, others are deliberate. No letters can be distinguished. The largest group of marks is several parallel lines set at right-angles to the footring, with some at one end crossed by a single angled line where the tool slipped. SF4323, Fill 6640, Pit 6641, Area H, Period 5. (Figure 457)

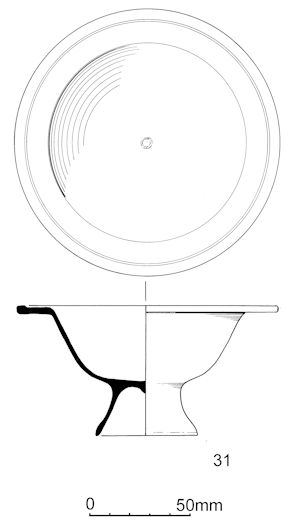

31. A flanged hemispherical bowl with beaded rim and pedestal base. External diameter 132mm, height 65mm. The vessel is lop-sided, which appears to be due to careless manufacture rather than secondary damage. The main part of the body is slightly asymmetrical, and thus the base looks to have been applied off-centre from some angles, and the rim is not level around the circumference. At the lowest part the rim is slightly worn. This may suggest that the vessel was always picked up at the same point on the rim when it was full and heavy, causing the rim to buckle slightly, though the chances of this occurring seem slight The surfaces all have horizontal striations from lathe-finishing, apart from the inside of the base which is rough with smeared solder. The inside face of the bowl has been pushed downwards into a point where the lathe centre was attached, but it does not appear to have been perforated and then plugged, as the other vessels in this group were. SF3419, Fill 6640, Pit 6641, Area H, Period 5. Figure 458

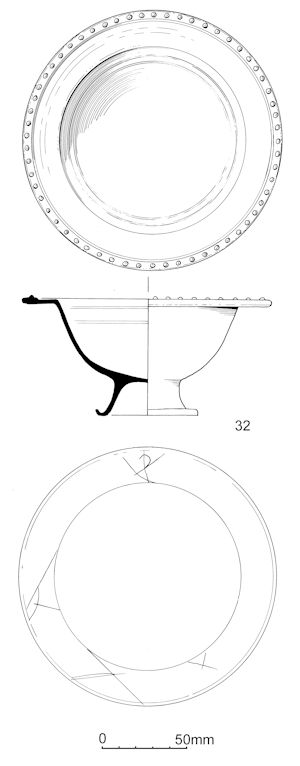

32. A flanged hemispherical bowl dish with slightly raised rim decorated with dots, and a pedestal base. External diameter 154mm, height 67mm. As on a dish from the temple of Sulis Minerva at Bath (Sunter and Brown 1988, fig. 5, 13), the dots were cast in one with the main part of the vessel. They are very worn on one side of the rim, and this part of the circumference is also slightly lower than the rest. This characteristic has also been noted for SF3419. There are horizontal lines all over the vessel from lathe-finishing. There is only a very faint mark from a lathe centre in the bottom of the dish, and there is no indication that it was pierced and then plugged. The inside of the base is rough from solder, but the underside of the main section is quite clean and was clearly not pushed outwards by the lathe centre as on SF3419. The foot of the base is out-turned. SF3420, Fill 6640, Pit 6641, Area H, Period 5

There is a Chi-Rho scratched beneath the rim, as well as a cross and some random scratches. Both for the simple cross and for the Chi-Rho, one line of X was made randomly, as it runs out from a scribing tool mark at the junction of wall and rim. The other line on each cross and the Rho are deliberate secondary additions. Most of the random marks were also made by a slipping tool. Figure 459

33. A flanged hemispherical bowl with low pedestal base. External diameter at rim 194mm, height 78mm. The edge of the rim is beaded and grooved at regular intervals, the latter done by drawing an edged tool across the bead from the outside in, apparently when the metal was soft as there is an extension of metal resting on the rim below each groove. A rim fragment from the temple of Sulis Minerva at Bath has a beaded and grooved rim, though it was suggested that those grooves were made with a file (Sunter and Brown 1988, fig. 5, 16). The pedestal base, which has an out-turned foot, was cast separately and soldered onto the bowl. Slight traces of concentric horizontal striations from being finished on a lathe can be seen on both surfaces of the rim, on the internal and external surfaces of the bowl, and on the outside of the base. The inside of the base is rough with smeared solder, with a marked concentration in the middle where the centre hole was plugged. A rough patch on the inside close to the plugged hole may also be a smear of solder, but is more likely to be corrosion. SF3421, Fill 6640, Pit 6641, Area H, Period 5. Figure 460

The copper-alloy vessel fragments include parts of a number of good-quality, early, imported vessels which suggest a high status for the Late Iron Age settlement. In particular, there is an escutcheon similar to a pair from the Lexden tumulus. The presence of these pieces does not necessarily imply that they were being directly imported through Heybridge; a more likely scenario is that they formed part of a gift exchange between chiefs, perhaps being a gift from the ruler of Camulodunum. Only one of the early vessel fragments comes from a dated context, a possible cup handle (SF1182).

There was a particularly low proportion of vessel fragments from dated contexts, a total of only four. They include, however, the following very fine imported jug.

Cite this as: Crummy, N. 2015, The copper-alloy jug, in M. Atkinson and S.J. Preston Heybridge: A Late Iron Age and Roman Settlement, Excavations at Elms Farm 1993-5, Internet Archaeology 40. http://dx.doi.org/10.11141/ia.40.1.crummy3

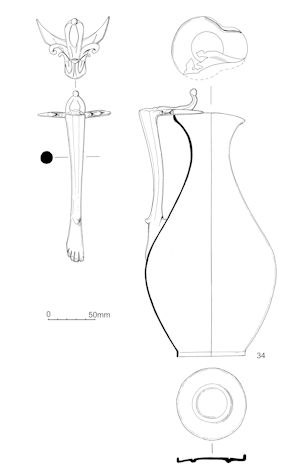

34. An ovoid copper-alloy jug, with the lower part of the body very damaged in antiquity and partly missing. Some of the metal may have corroded away during deposition. The vessel was pulled out of the ground during topsoil-stripping, but seems to have suffered little damage as a result. The base-plate and handle, both made separately, are now detached. Ht 268 mm. SF2996, Fill 15369, Pit 15368, Group 696, Area M, Period 4

The main body of the vessel was shown by X-ray fluorescence analysis to be made of a copper-tin alloy, while both the handle and the base had a high lead content. Traces of lead solder were found where the handle and base were attached to the main body (A. Sutherland, AML Report, unnumbered). The handle and base-plate were cast. The body is very thin but was also probably cast rather than raised. The core of a mould for the body could have been broken up and raked out through its open bottom (Strong and Brown 1976, fig. 38). Slight turning marks on the neck suggest the body was then finished on a lathe.

The rim, much damaged on one side, was slightly thickened and has a wide pouring lip, though this is not usual with vessels of this type. Though one side of the lip is damaged, it is clear that the constriction on the other side is deliberate, and that the rim is lower at the lip than elsewhere on its circumference. The maximum rim diameter is 80mm. The body has a maximum diameter of 135mm. The base-plate is 76mm in diameter, and has a raised edge to fit over the body. There is a considerable quantity of solder around this edge. There is a small footring, which is matched by a shallow groove on the upper surface. The base-plate does not appear to have been lathe-finished, as there is no visible centre-mark, and the inner and outer junctions of the footring with the plate are not neatly scribed but irregular. The footring does not lie flat, but on one side lies above the outer edge of the base. The handle is stoutly cast and for the most part is of slightly facetted circular section. The upper part, which was soldered to the rim, is in the form of a lotus bud, with the side petals extended to form angular terminals that can be identified as vestigial birds' heads (Radnóti 1938, 167), and the bud itself is turned upwards and tipped by a globular knob to form a thumb-rest. Much of the detailing of this design has been engraved after casting. The attachment scar where the base of the handle was soldered on is clearly visible on the body. The terminal is in the form of an extended, naked, human right foot, with a small curled leaf on the front of the ankle.

Jugs with the handle terminating in a human foot, have a wide distribution from Thrace across to Britain but are found chiefly in the northern provinces of Pannonia, Germania, and Gallia Belgica, where they appear to follow the trade routes of the Danube and Rhine, with a trail also apparent in central and southern Gaul along the valleys of the Rhône and Saône (Sedlmayer 1999, Karte 3). Lists of known examples can be found in Tassinari 1973, and Szabó 1981 and 1983, to which may be added an example from Trier (Pirling 1993, Abb. 8, 1), and this example from Elms Farm, which is only the third foot-handle jug recorded from Britain, the others coming from Hauxton, Cambridgeshire (Hurrell 1904, 496, pl. 23, b; Eggers 1966, Abb, 39, c; Liversidge 1958, 9), and Corbridge, Northumberland (Forster and Knowles 1913, fig. 1).

The foot may be the right or the left, and may be naked or sandalled, with the sandal shown by white-metal strips. Occasionally a pair of feet are used, as at both Hauxton and Corbridge (Liversidge 1958, 9; Forster and Knowles 1913, fig. 1). The toe-nails are usually clearly shown. There is often a curled leaf above the foot, though at Hauxton this feature is more like drapery (see below). On some handles both the foot and the leg may be realistically modelled, to the extent of showing the individual joints of the toes and the muscles of the calf (Szabó 1983, pl. 13; Sedlmayer 1999, Taf. 6, 2), but on many jugs the anthropomorphic design ceases above the foot, with the main part of the handle of simple square, facetted circular, or polygonal section.

The form of the upper part of the handle on these jugs is generally plain and angular, apart from some detailing of the vestigial birds' heads on the tips of the arms, and some slight moulding or engraving of the central part. Some examples have a thumb-rest in the form of a curled central leaf, equivalent to the lotus bud here, others not. The identification of the tips of the arms as vestigial bird's heads can be clearly understood by tracing them back from slightly better-defined examples (e.g. Tassinari 1975, pl. 34, 174, 179), to the well-executed heads of geese, some emerging from volutes, on other vessels dating back as far as the 5th century BC (Bini et al. 1995, 50, tav 33-7; Mariën 1970, figs 2, 9-10; Koster 1997, 29, no. 6; Sedlmayer 1999, Taf. 20).

The elaborate Elms Farm handle and its use of the lotus bud motif appears to be unparalleled on these jugs, and suggests a strong link back to the Graeco-Roman tradition. The seeming inconsistency between the quality of the lotus decoration and the lack of any attempt to model the main part of the handle in the form of a human leg supports Szabó's suggestion that the detailing was done by professional engravers who had not been involved in the manufacture of the original mould (1983, 93). The Hauxton jug can also be related back to early Italy in that the feature above the feet, usually, where present, a simple curled leaf, here resembles drapery with folds hanging down on either side of the feet, with a 'kick' in the centre. This feature is also found on the handle of an Italian spouted jug dated to the 3rd century BC, where the base escutcheon shows a pair of feet emerging from drapery hanging in very delicate folds and with a central 'kick', itself related back to 6th-5th century BC Ephebe-jugs (Bini et al. 1995, tav 14, 1a-b).

Tassinari divides jugs of the Roman imperial period with a human foot at the base of the handle into two groups, western and eastern (1973; 1975, 69), both of which may or may not have a thumb-rest (Szabó 1983, pl. 18). Vessels of her western group are tall and slender in form, having an extended cylindrical lower body, and the Hauxton and Corbridge jugs are of this form. The body of the eastern variety is ovoid, and it is to this group that the Elms Farm jug belongs. It is the most westerly example of the group, the next closest being from Strasbourg (Germ Rom 1924, A2 V, Taf, 7, 4). The Strasbourg jug, like that from Elms Farm, has a pouring lip defined by lateral constrictions on the rim, though it does not appear to dip down below the level of the rest of the rim.

The type is long-lived, but production of both the eastern and western forms probably began in the second half of the 1st century (Sedlmayer 1999, 19), with the western variety made initially in Gaul, then along the Danube in workshops opening up in the 2nd century (Szabó 1983, 91-2). The eastern type may have been made in Pannonia (Radnóti 1938, 167-8), though fragments of moulds for handles terminating in human feet have been found at Tortosa (Spain), and in Syria (Tassinari 1973, pl. 13, 1-2). The difference between the distribution of the two types, the western clearly following known trade routes, the eastern form much more widely scattered, with examples in (Syria (1), Thrace (1), Pannonia (3), Italy (1), Germany (3), Gaul (1), and now also Britain (1), has led Sedlmayer to suggest that production of the latter took place in a workshop aiming principally for an export market (1999, 19). The slight concentrations in Pannonia and Germany appear to support an argument for production in the Danube-Rhine area, but the presence of mould fragments as far apart as Syria and Spain and the very wide range of modelling abilities shown by the feet alone, suggest that both eastern and western forms were probably made over a long period, in many workshops, in several provinces.

That the Elms Farm jug may be a comparatively early product is suggested by the pouring lip, which shows some affinity in its form to trefoil-mouthed jugs, and by the quality of the lotus motif, but is contradicted by the comparative plainness of the rest of the handle, and by the poor quality of the base. On balance, a date in the first half of the 2nd century is most likely for its manufacture.

There is a strong pattern of deposition noted by Szabó for foot-handle jugs on the continental mainland. There eastern type jugs derive mainly from graves, while many of the western type have been recovered from contexts associated with water, such as rivers, sanctuaries, springs and wells, prompting the suggestion that they were deliberately made as ritual vessels (Szabó 1981, 63-4). In a combination of both contexts, a western type jug from Tongeren was found in a hoard with pottery vessels deposited within a cemetery (Vanvinckenroye 1984, 215).

How far the British foot-handle jugs conform to Szabó's pattern is difficult to ascertain. The precise context of the Hauxton jug, recorded as found with two other metal jugs, and perhaps pottery and glassware as well, is unfortunately not known, and there is no guarantee that all the vessels were directly associated when buried (Hurrell 1904, 496; Liversidge 1958, 11). They may be a single hoard, or from a single rich grave, or from several graves. However, the site from which it came lies close to the River Granta, making conformity to Szabó's pattern for the western group a possibility.

The same is unlikely to be true for the Corbridge jug, which came from Site 43 within the eastern military compound, just south of the Stanegate. Three temples lay on the other side of the compound wall, and it was found in a pit or soil layer in close, if not immediate, association with a bone plaque carved with a representation of a Mother Goddess bearing a pile or basket of fruit in her lap (Forster and Knowles 1913, 234, 275-6, fig. 22). The intervening wall militates against any association between the jug and one or other of the temples, but their proximity is tantalising.

Though the Elms Farm jug is of the eastern type, which Szabó notes as coming in general from graves, it was found in a small pit within one of the strip plots fronting onto Track 3, the approach road to the temple precinct. As with the Corbridge jug, the proximity to the temple is tantalising, but no direct association can be established.

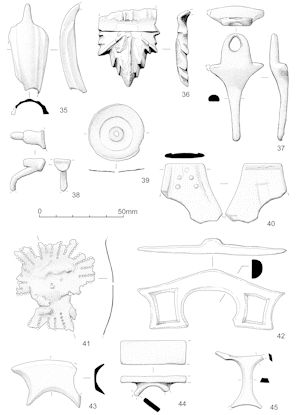

35. Fragment of a vessel attachment in the shape of a bird, possibly a dove, probably from a vessel with slightly curved sides. The object is hollow backed, with the outer face ribbed to suggest the wings. The head of the bird is missing. The inner face is roughly finished. In good condition. Eggers (1966, nos 41 and 51) gives parallels from Barton, Cambs., and Ashby, Lincs., both rather more strongly modelled, and from straight-sided vessels. However, the general form is similar enough to suggest that this piece was a continental import. L. 54mm, max. W. 24mm. SF795, Machining layer 4000, Area A, unstratified

36. Cast, vine leaf-shaped escutcheon, flat backed. It is deeply moulded and rather heavy, with a ribbed top element bent at right angles, and broken. It is in poor condition, with the surface partly spalled off. It is very similar to a pair of escutcheons from the Lexden tumulus (Foster 1986a, 63, nos 6 and 7) which were probably from a large bowl, and which were probably deposited c. 15-10 BC; a further example from Essex was found in an unstratified context at Fingringhoe. The type is continental, and Augustan in date (Foster 1986a, 176-7). This object therefore belongs to the Iron Age phase of the site, and was part of a luxury, imported item. L. 46mm, W. 36mm. SF4823, Machining layer 12000, Area R, unstratified

37. Bucket or bowl escutcheon. In fair condition. It is complete as buried, and comprises a rod, expanding into a curved triangular element with a rounded pierced lug on the top, worn and cracked across the top. There is no visible means of attachment, and it was presumably soldered on. It is similar in general shape to an escutcheon from Aldborough (Bishop 1996, 14, no. 22), although the latter is hollow backed. 64mm, max. W. 31mm, lug L. 18mm, W. 16mm. Hole 8x7mm. SF8193, 3999, Spoil-heap

38. Fragment, probably part of the handle from a small cup. A curved rod springs from a small block element with a curved end. This is possibly a rather rustic form of a first-century AD type of handle illustrated by Strong (1966, fig. 27f). L. c. 26mm. SF1182, Fill 4286, Pit 4285, Group 62, Area K, Period 2

39. Cast disc with a central perforation. The top has moulded concentric lines. In fair condition, with slight damage to the edge, and slightly buckled. Probably a lid. Diam. 34mm, hole diam. 3mm. SF6629, Fill 15463, Post-hole 15466, Area M, Period 3

40. Fragment from a flat, tapering skillet handle, with the edge of the suspension hole present. The top has a line down each edge, and five stamped rings arranged in a V-shape. The maker's name is probably stamped on the back, but is incomplete, and illegible. This side also has one incised transverse line; most of the surface between this line and the surviving end has flaked off. The lines along the edge are a fairly standard feature of such handles, with an example from Vindolanda (Bidwell 1985, 126, no. 73). The narrower end appears to have been cut, and this may be scrap metal. In fair condition. L. 35mm, W. 24mm-c. 50mm. SF929, Machining layer 4000, Area A, unstratified

41. Fragment from the centre of the base of a strainer. It is slightly dished, and has lines of holes, diam. c. 0.75mm, radiating from a plain centre with a single central perforation. The metal has broken along the holes. Fair condition, with a light covering of earth. This may be a continental import, as is suggested for a more complete example from Great Wakering, Essex (Eggers 1966, no. 34), now in the British Museum. c. 60x51mm. SF471, Cleaning layer 6000, Area H, not dated

42. Strainer handle, in good condition. It is paralleled at Baldock (Stead and Rigby 1986, 13, 6 no. 368), citing an example on a strainer from a hoard from Crownthorpe, which dates to the second half of the 1st century AD. 87x37mm. SF925, Machining layer 4000, Area A, unstratified

43. Bucket foot, incomplete, hollow backed; from a vessel with a base diameter of c. 140mm. Surviving dimensions 45x26mm. SF1864, Machining layer 4000, Area A1

This is a less ornate version of an imported type that has previously been found elsewhere at Heybridge (Eggers 1966, no. 35 and Abb. 58), and the form of the bucket to which such a foot would have belonged can be seen in Eggers 1951, Tafel 4.24 and 4.30. These buckets normally had six feet, quite closely spaced, which were soldered on to the vessel. The Elms Farm foot may have come from a bucket with eight feet, fitting neatly round a circle of 140mm diameter, with a gap of c. 4mm between the outer points, and the same distance between the inner points. Similar feet of various shapes have been noted from sites including Colchester (from the Boudiccan destruction debris; Crummy 1983, 73, no. 2051), Gorhambury (from a 4th-century context, therefore ?residual; Wardle 1990, 126, no. 171), and Camerton (Jackson 1990, 46, no. 123). The other foot from Heybridge may be from a rich 1st-century grave at the Towers, Heybridge, whose other grave-goods include a bronze flagon and patera, now lost, and possibly a Koan amphora (Wickenden 1986, 55). Eggers illustrates the patera alongside the foot, and while not explicity stated, it can be assumed that they are part of the same find. Wickenden, however, has some doubts about the provenance.

44. Fragment from a moulded object, comprising a straight bar, probably complete at one end, with the other end broken in antiquity, with a slightly narrower curved bar tangential to one face. This somewhat resembles part of a lock bolt, but is much larger than normal. It is probably part of the handle of a 1st-century AD cup, the shape as Strong 1966, 134, fig. 7 (c) or (e). L. 38mm, W. 14mm, Th. 4mm, Ht 12mm. SF3756, Machining layer 11000, Area A, unstratified

45. Cast I-shaped object with curved cross elements, flat backed and with most edges chamfered. One cross element is complete on one side and broken on the other. The top edge is chamfered, and has file marks. The other cross element is shorter, and was possibly a flat ring; one side has a recent break, the other was probably broken in antiquity. This is probably a small vessel handle, from an open form such as a bowl. L. 44mm, max. surviving W. 29mm. SF4671, Machining layer 11000, Area A, unstratified

46. (Note by M. Henig) Appliqué, probably attached to a small box or vessel. It is in the form of a male head with a somewhat elongated skull, probably intended for a negro. Around the figure's neck is a chain from which is suspended a crescentic amulet. There is a depression in the crown of the head, perhaps intended for a suspension loop. Ht 23mm. For the facial type on a balsarium see Mitten and Doeringer 1968, 308 no. 310; and see Nenova-Merdjanova 1997, 105 and 107, for amulets worn by figures on other such bust-vases. SF3590, Machining layer 11000, Area A, unstratified

47. Mount, probably from a vessel, in the shape of a horse's head, rather poorly modelled, with a hollow back. There is no detail of the eyes, and the ears and crest of the mane are very angular. The mane is suggested by three incised lines either side, echoed by two sets of three incised lines round the base of the mount. Ht 23mm. SF3593, Machining layer 11000

48. Vessel fragment, probably from a bowl. Rather distorted, and probably burnt. Diam. c. 164mm. SF2338, Layer 6270, Group 1000, Area H, not dated

49. Not illustrated. Vessel rim fragment in good condition, with a dark patina. The rim is slightly thickened. It is from a large, cast vessel with a wall angle of c. 70° to the horizontal. The outer face is rather poorly finished, with circumferential striations. Possibly post-Roman. Th. 3mm. SF8148, 3999, Spoil-heap

50. Not illustrated. Vessel rim from a thin-walled, wide-mouthed vessel with a slightly thickened everted rim, presumably a bowl, with white-metal coating, probably tinning, on the inner surface. In fairly poor condition, surface flaking. Diam. c. 160mm, rim W. 4.5mm. SF1630, Cleaning layer 6048, Area H, not phased

51. Not illustrated. Vessel rim, cast. A thin, plain rim, slightly thickened. 20x9mm. Possibly Roman. SF9527, 3999, Spoil-heap

52. Not illustrated. Vessel rim, probably a bowl. A simple everted rim, with only a small part of the body surviving. Diam. 163mm. SF3658, Machining layer 11000, Area A, unstratified

53. Not illustrated. Plain cast vessel rim fragment, from a closed form such as a jug. SF9527, 3999, Spoil-heap

54. Not illustrated. Rim fragment and three detached pieces from a bowl. The rim is plain and unthickened, the surface in fairly poor condition, and encrusted. There is a perforation 6mm below the edge. The surface is uneven, and may have moulded decoration, although this could be an artefact of corrosion. Diam. c. 160mm. SF5660, Fill 16073, Pit 16088, Group 559, Area H, Period 4

55. Foot, probably from a vessel. An angular foot, triangular in side view, with a D-sectioned leg, broken in antiquity. Each side of the foot has three grooves, and there is a step at the bottom of the leg. The surface is partly flaked, with recent damage to the toe. L. 32mm. SF1862, Machining layer 4000, Area A, unstratified

56. Not illustrated. Cast fragment. A slight tapering rectangular terminal with a slightly rounded top, broken at the wider end. The back is flat and rather rough, with traces of lead-based solder. There are two transverse incised lines adjacent to the break. Probably part of a vessel fitting. L. 27, W. 19-24mm, Th. 5mm. SF7230, Machining layer 11000, Area A, unstratified

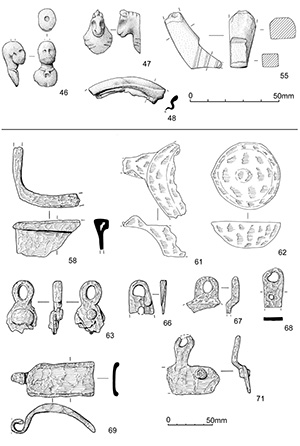

Vessels made out of iron must have been far more common than the archaeological record suggests, since the thin sheet from which they were made corrodes so readily. Even where it is possible to identify fragments as vessels (Figure 463), it can be difficult identifying the form. The site produced an almost complete frying pan, a very rare find that survived only because it had been held together by a thick, pebbly concretion; however, there were fragments from at least one other frying pan, suggesting that they were in fairly common use. The type is discussed by Manning (1985a, 104), who notes that most are later Roman. The only other definite vessel fragment is the rim of a square or rectangular vessel, and there are also fragments that may be the binding from a wooden vessel.

Handle mounts are more abundant, either plates with perforated lugs, or strips with terminal loops, the latter being normally termed bucket mounts.

57. Not illustrated. Two plates, one on top of the other, with at least six small perforations in one plate. The edges are somewhat damaged, but one is probably a strip 30mm wide, with a square terminal, and the other is at least 43mm wide and 56mm long. There is mineralised wood on the back; the way that the grain lies suggests that the wood may be associated with the iron. This is therefore probably part of the binding from a wooden vessel. SF6313, Fill 8785, Pit 8786, Group 48, Area P, Period 2

58. Vessel rim, from a vertically sided vessel with a right-angled corner. The rim was formed by bending the edge of the sheet over to form a squared bead, now variable in section because of loss of metal due to corrosion. It survives to a height of 38mm. SF1548, Fill 9064, Pit 9029, Group 783, Area D, Period 3B

59. Frying pan, almost circular, originally with a folding handle. It is almost complete bar the handle, but somewhat distorted, the metal brittle and cracked, and with part detached and fragmented. Only the largest of the detached fragments has been included in the illustration. The pan is covered in concreted gravel. There may have been a lip, but this would have been on the part of the rim which is missing. The surviving part of the handle has the stubs of the flanges that would have held the folding part, and a short, narrower projection at the end. Pan W. 200mm, L. 235mm, ht 23mm. Handle L. 48mm, W. 26mm. SF458, Cleaning layer 6000, Area H, not phased (Figure 464)

60. Not illustrated. One larger and four smaller fragments from a frying pan. The largest piece comprises the start of the handle, with the flanges broken off, and a segment of the side of the pan, broken along the edge of the base. The fragment is now somewhat distorted. The other fragments are parts of the side. The diameter is not measurable. Side Ht 30mm, handle W. 29mm, surviving L. c. 55mm. SF6626, Fill 15355,Pit 15356, Group 701, Area M, Period 6

61. Part of a handled vessel, probably a small frying pan. The handle was probably socketed, and is probably perforated. For parallels see Manning 1985a, 104, P32-3. The type is typically Late Roman. If circular, the diameter would be c. 150mm. Ht of side 27mm. SF5674, Machining layer 11000, Area A, unstratified

62. A small hemispherical bowl with a slight lip on one side, broken but nearly complete. There is no indication of a handle. Diam. 72mm, depth c. 30mm. SF6978, Fill 11321, Post-hole 11322, Group 1253, Area N, not phased

The function of this object is somewhat in doubt. It is possibly the base of a small covered lamp, similar to the base of a mid-1st century covered lamp from Hod Hill (Manning 1985a, 98, P2). The type is rare in Britain, and possibly exclusively early in date. However, the bottom of the nozzle does not appear to be present, and this could be a simple open lamp. A very similar bowl from a 1st-century context at Caerleon (Zienkiewicz 1993, 116, no. 3) was interpreted as having a metallurgical function, as it has what appeared to be vitreous slag on the base. There is no metallurgical waste from post-hole 11322, although there is a small amount of ceramic kiln debris. A third alternative is that it is a ladle bowl, though there is no sign of it ever having had a handle.

63. Iron handle mount. It comprises an oval loop, with a thinner bifurcated plate at the base. The edge is cracked and incomplete, and may have been oval originally. There is a small detached portion which has not come out on the X-ray. There is a piece of copper-alloy sheet sandwiched between the two iron leaves, fastened by an iron rivet with a large, kidney-shaped head (possibly damaged in antiquity) and a small circular back. The copper-alloy sheet does not appear to reach the edge of the iron plate on one side, but both metals are in poor condition, and the X-ray is not very clear. The copper alloy is presumably part of a sheet vessel, with the iron handle clipped over the rim and riveted on. L. 59mm, W. of loop 25mm, th. of loop 10mm. SF5649, Prepared surface 16023, Group 72, Area H, Period 2B

64. Not illustrated. Strip fragment with a rounded terminal, perforated. On the X-ray it appears that the loop was made by bending the end of the bar round and hammering it down well, rather than by punching a hole through. This type of loop was often used on latchlifter handles, but this would be very large for a latchlifter, and it is more likely to be a bucket handle mount, broken just above where the first rivet would have been. L. 54mm, W. 32mm, hole diam. 14mm. SF1834, Fill 10054, Pit 10026, Group 789, Area E, Period 3

65. Not illustrated. Bucket handle, c. 50%. In three joining pieces, one of which has come out very poorly on the X-ray, as the metal is extremely mineralised. The handle has a rectangular section, hooked at one end, with a strip hand-hold curved widthwise. It is similar to Manning P18. From a bucket of diam. c. 240mm. The drop of the handle is c. 170mm. Section 14x5mm. The condition of the metal is typical of a waterlogged context such as a well; although the pit was not waterlogged at the time of excavation, it may have been in the past. SF1538, Fill 9039, Pit 9038, Group 806, Area D, Period 4

66. A small bucket handle mount, broken across the lower hole. The loop has a D-shaped perforation, and the metal is thicker at this end. For the general shape see Wickenden 1992, 82 and fig. 42.5. L. 38mm, W. 30mm, hole diam. 18mm. SF7021, Fill 10897, Pit 10953, Group 673, Area N, Period 4

67. Vessel handle mount. Rounded terminal with a large perforation. It is on the edge of, and a slight angle to, a wider plate of unknown shape, broken off at the angle. SF5911, Layer 15112, Group 5018, Area M, Period 5

68. Bucket handle mount with a large, almost D-shaped, perforation in the rounded terminal, and a nail or bolt through the square end. SF5990, Layer 16187, Group 573, Area H, Period 5-6

69. Strip, curved lengthwise, with a low flange along each edge on the convex side, and a loop at one end. Probably a vessel handle. L. 96mm, W. 38mm. SF1958, Fill 4692, Slot 4695, Group 1161, Area K, not phased

70. Not illustrated. Handle fragment, distorted and broken. Made from a strip with a concave section, tapering slightly to a looped terminal. Probably a bucket handle. W. of strip 28mm, W. of terminal 23mm. SF5672, Machining layer 11000, Area A, unstratified

71. Probable vessel handle mount. An incomplete plate, probably originally oval, with one nail in situ. One long side has a slightly curved strip at right angles, with a perforated terminal, now damaged. Plate 57x31mm, strip 44x18mm, hole diam. 10mm. SF6179, Cleaning layer 14479, Area L, not phased

72. Not illustrated. Circular swivel loop, in two pieces, with most of the perforation missing. A small part of the hook, which had a knobbed terminal, was corroded on. External diam. 60mm, rectangular section, c. 8x4mm. Surviving L. of hook 27mm, terminal diam. 9mm. 16163, Foundation trench 16196, Group 567, Area H, Period 5

73. Swivel loop, possibly from a cauldron chain, with the end of the loop wound round the shaft. Bent. The loop is very thin at the bottom, possibly the result of wear. L. 95mm, external diam. of loop 35mm. SF2015, Cleaning layer 5307, Area J, Period 5-6

74. Swivel loop, in poor condition, possibly from a cauldron chain. It comprises an oval ring with a ?lentoid plate for the swivel to go through. The swivel ends in a loop. Ring, external diam. 65mm, internal diam. 53mm, swivel L. 100mm. SF891, Layer 6026, Group 8001, Area H, not phased

Where noted, stone identifications are by Dr G.K. Lott of the British Geological Survey (GKL). Other identifications are by the author.

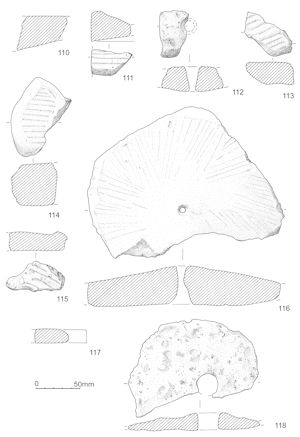

Ten pieces of stone were identified as being definitely or possibly from saddle querns. Small fragments of saddle quern may be difficult to spot, particularly as the stones used for saddle querns in Essex seem to have been predominantly local erratic boulders, and those from Elms Farm are no exception. The only possible saddle quern fragment in a definitely non-local stone may be Greensand, from the Hastings Beds (no. 80). This is also the only saddle quern from a potential pre-Roman context. Greensand is the most common non-local stone used for saddle querns in Essex, with at least twenty-six other examples known. They occur in Late Bronze Age and later contexts, principally in coastal locations, including one from a Late Bronze Age context at Heybridge Basin (Major 1988a).

While saddle querns are a prehistoric form pre-dating rotary querns, their use continued throughout most of the Iron Age, alongside rotary querns. At Danebury, for example, although rotary querns first appear in contexts dating to the 5th century BC, saddle querns remain the more common type until perhaps the 1st century BC. It is therefore difficult to say whether the possible Period 2 Greensand quern is residual, or contemporary with its context, which is dated to the mid-1st century AD.

The other possible saddle quern fragments may be residual from the earlier occupation of the site, or may been brought to the site during the Roman period for use as building stone, although only one piece formed part of a structure at the time of excavation. This was a piece from a Period 6 oven (20137; no. 83), from which nearly 30kg of stone was recovered in a variety of types, mostly unworked.

Traces of reuse can be difficult to see on saddle querns, since their surfaces may not be as regular as that of a rotary quern in the first place, and secondary abrasion may not be very obvious. However, at least one example from a Roman context (no. 77 below) was definitely used as a knife-sharpening stone.

The distribution of the saddle querns appears to be of no particular significance. The largest number of fragments from one area was three from H (Table 81). Although this is 30% of the total number, it seems presumptuous to describe this as a concentration.

| Area | No. | % |

|---|---|---|

| H | 3 | 30 |

| I | 1 | 10 |

| K | 1 | 10 |

| L | 2 | 10 |

| N | 2 | 20 |

| W | 1 | 10 |

| Total | 10 | - |

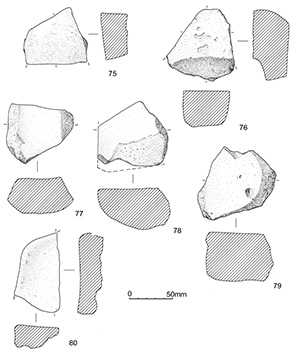

75. Fine-grained sandstone, well cemented. Saddle quern fragment, made on a natural boulder, with the full width probably present. The original boulder surface remains on one side, although the rest of the surviving edge has been deliberately shaped. The underside has been crudely split, giving a variable thickness to the stone. The grinding surface is flat and well finished, with areas of polish round the edge. Wt 1350g. SF180, Fill 3743, Post-hole 3744, Group 1284, Area W, not phased

76. Sarsen? Saddle quern fragment with a flat, smooth grinding surface. Wt 2950g. Layer 6316, Group 547, Area H, Period 4

77. Possible edge of a saddle quern, reused as a sharpening stone. It has one smooth, slightly dished surface. The underside is partly irregular, though smooth, and the edge partly smoothed. One broken edge has a possible knife-sharpening groove on it (though this might be modern damage). Identification (GKL): pale pink, very fine grained, porous, non-calcareous sandstone. Possibly Triassic; Triassic sandstones outcrop extensively in the western portion of the UK from the Dorset coast, through the Midlands into Cumberland. Th. c. 35mm, c. 75x70mm, Wt 248g. Fill 11414, Slot 11415, Group 683, Area N, Period 3

78. Quartzitic sandstone. Probably the corner from a small, well-finished, saddle quern made on an erratic pebble, with a smooth grinding surface and a rounded edge. The surfaces are well finished. The original width was perhaps c. 110mm. Wt 368g. Surface 13045, Group 381, Area H, Period 3

79. A saddle quern fragment worked on a natural boulder, with a smooth grinding surface and a roughly shaped edge. The bottom has been left in its natural state. Wt 4250g. Identification (GKL): Quartzose sandstone, possibly Millstone Grit Group or Coal Measures. Fill 16253, Post-hole 16254, Group 548, Area H, Period 4

80. Shaped fragment, probably the edge of a saddle quern (cf. North Shoebury), but possibly a plaque. The edge is nicely shaped, the bottom eroded. The grinding surface is smooth, but not polished. Surviving L. c. 185mm, surviving Th. 72mm. Identification (GKL): Bioclastic sandstone, possible source in the Upper Jurassic, Purbeck sandstone or Lower Greensand (Hastings Beds). Wt 1485g. Fill 4767, Pit 4779, Group 93, Area K, Period 2

81. Quartzitic sandstone. Fragment from the rounded end of a saddle quern, worked on a natural boulder. The edges have been crudely shaped, the underside is natural. The grinding surface is smooth and slightly dished. c. 150x100mm, max. T. 79mm. Wt 1575g. Layer 5494, Group 631, Area I, Period 3B

82. Pebble fragment, medium-grained sandstone. Scorched. Possibly the edge of a saddle quern or rubber. Wt 58g. Fill 4142, Pit 4141, Area K, not phased

83. Quartzitic sandstone. An edge fragment from a waterworn, rather flat, natural pebble. One face may have slight polish, perhaps from use as a rubber, or possibly a saddle quern. c. 85x80x60mm. Wt 710g. Fill 20093, Oven 20137, Group 721, Area L, Period 6

84. Quartzitic sandstone. A fragment, probably part of a saddle quern; definitely used as a rubber, at the very least. The 'edge' is natural, the adjoining surface smooth and slightly dished. Wt 605g. Fill 23010, Pit 23012, Group 694, Area N, Period 4

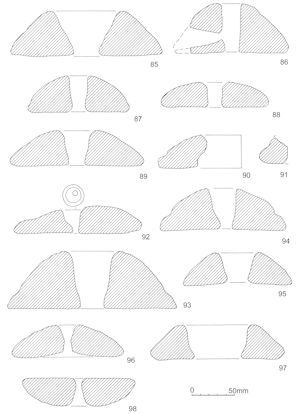

| Part | No. | % |

|---|---|---|

| Lower | 1 | 3 |

| Lower? | 2 | 6 |

| Upper or lower | 9 | 29 |

| Upper | 14 | 45 |

| Upper? | 1 | 3 |

| Not definitely quern | 4 | 13 |

| Total | 31 | - |

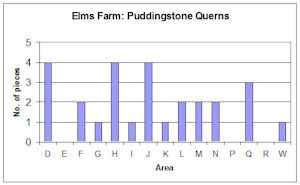

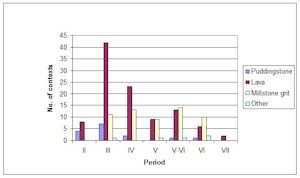

Thirty-one quern fragments of possible or definite querns came from twenty-seven contexts, forming the largest excavated group of puddingstone querns from the county. Four pieces had no surviving finished surfaces, and may not have derived from querns. In particular, the single piece of puddingstone from Area W was partly weathered, and may have been a natural erratic. As is usually the case, there were more upper stones than lower stones present; the numbers of each are shown in Table 82. The ratio of definite upper stones to definite lower stones known from the county was 89:11 (data recorded in 2000, a total of 118 stones), while the ratio at Elms Farm is 93:7. Why there should be such a strong bias towards upper stones is unknown, although it is certainly easier to recognise a small fragment from an upper stone, particularly if part of the hopper is present.

The distribution of the fragments across the site is not very informative (Figure 466). No area had more than four fragments, and Areas E and P had no puddingstone at all. They were virtually absent from the Hinterland Zone, with a single, dubious fragment from Area W, but the numbers from the other zones were almost identical, with seven from the Northern Zone, nine from the Central Zone, and ten from the Southern Zone. Three of those from the Central Zone (all Area J) are from post-Period 3 contexts, and may or may not be redeposited from other areas. There is therefore no indication that the use (or at least the discard) of puddingstone querns was confined to a particular part of the settlement.

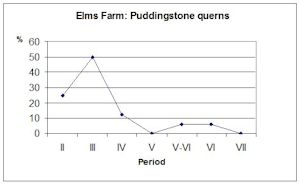

Seventeen fragments came from dated contexts. Deposition of puddingstone on the site is strongly concentrated in Periods 2 and 3 (Figure 467), with half the querns from closely dated contexts coming from Period 2 alone. By the end of Period 3, 75% of the quern fragments in dated contexts had been deposited. There is no evidence for extensive reuse of puddingstone querns as building material; only one of the five pieces from post-Period 3 contexts came from a construction (Oven 15984).

Prior to this excavation, no puddingstone querns had been recovered from an Iron Age context in Essex, despite the bun-shaped form being essentially pre-Roman. Even outside Essex, there are very few examples from Iron Age contexts, mostly dubious. There is, for example, a fragment from West Stow (West 1990, 93). The writer has not seen this stone, and considers that some doubt must remain that it is part of a rotary quern, since puddingstone was also occasionally used for saddle querns, as with a probable example from Woodham Walter, Essex (Buckley et al. 1987, 16). King (1986, 74, no. 55) lists a 1st-century BC quern from Leagrave. This was from a 19th-century excavation, apparently from a sealed context.

Four of the pieces from Elms Farm are from Period 2 contexts (Late Iron Age and Roman transitional). Two are layers (9717 and 17201) with earliest Roman pottery present. The other two pieces are from pits, one of them the 'Event Pit', 15417. Although the main deposit in this pit dates to about AD 10 at the latest, the quern is from the top layer, which could be later. However, J. Compton is of the opinion that it was probably deposited by AD 25. The quern shows little sign of wear, and was presumably fairly new when deposited. The second is from the single fill of pit 4203, which is less closely dated, and is early to mid-1st century AD. The handle hole of the latter quern is very close to the grinding surface, suggesting that it had worn considerably by the time of deposition. Neither of these pit fills is sealed, and while they could be intrusive, it seems likely from this evidence that puddingstone querns were in use by about AD 25. The fact that the bulk of the fragments were discarded in Period 3 suggests that they continued in use into the Early Roman period. Presumably, most would only have been discarded when they broke, or became too worn to work efficiently.