Elms Farm produced a large assemblage of artefacts used in all stages of textile processing, from the initial combing of the wool, to the production of sewn clothing. The most noticeable components of the assemblage are the spindlewhorls, a total of eighty-four, and the triangular loomweights, fragments from over 140 examples of which were recovered.

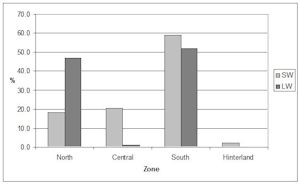

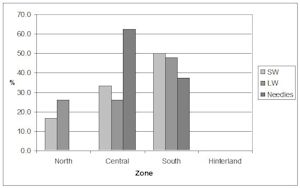

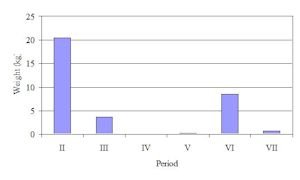

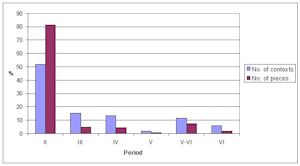

A large proportion of the spindlewhorls (54%) and loomweights (56% by weight) came from Period 2 contexts, and it is clear that the production of woven textiles must have been a major occupation during this period, continuing at least into the early part of the Roman era. Thereafter, the evidence is more difficult to interpret. The introduction of the horizontal loom to Britain by the Romans meant that loomweights were no longer needed, and all triangular loomweights from contexts after about AD 120 should be residual. There are ten spindlewhorls from contexts that are mid-Roman or later, but six of these are made from Late Iron Age grog-tempered fabrics, and are probably residual. It is feasible that spindlewhorls were made from sherds of pot over a hundred years old at their time of reuse, but the high proportion of whorls in this fabric would suggest a deliberate choice of 'antique' pottery, which seems unlikely. Of the remaining four spindlewhorls, two were made from sherds of (probably contemporary) greyware, one from septaria, and one from shale. There were no bone spindlewhorls. Unless the spindlewhorls in use at Elms Farm were made of perishable materials such as wood, it seems likely that the probable tally of four spindlewhorls of mid-latest Roman date does represent a decrease in spinning activity.

| Period | 2 | 2-3 | 3 | 4 | 5 | 5-6 | 6 |

|---|---|---|---|---|---|---|---|

| Iron woolcombs | 4 | 1 | |||||

| Bone metapodial tool | 1 | ||||||

| Bone weaving comb | 1 | ||||||

| Bone needles | 1 | 2 | 3 | 1 | |||

| Iron needles | 1 | 3 | 1 | 1 | 1 | 2 | |

| Copper-alloy needles | 3 | ||||||

| Total no. of objects | 1 | 1 | 12 | 5 | 2 | 3 | 2 |

An examination of the other textile implements from dated contexts reinforces the impression of a drop in textile-related activities at Elms Farm after Period 3. Figure 532 demonstrates that over half of the implements from dated contexts belong to Periods 2-3. Of those from later contexts, the bone weaving comb is a residual Iron Age object, and the metapodial tool is probably of similar date. Iron woolcombs appear to have been in use throughout the Roman period, so the single later Roman example from Elms Farm may not be residual.

It is also evident from Figure 532 that needles are particularly common at Elms Farm in Period 3 but not in Period 2 contexts, despite the abundance of evidence for textile production in Period 2. It might be expected that Period 2 needles would be predominantly made from bone, but since there was only a single needle from the period, it is impossible to comment. It should be noted here that bone objects as a whole were poorly represented in the assemblage from Elms Farm, particularly in Period 2; there was only one other bone object (a handle) from this period. The reason for this is unknown, and could possibly be due to poor bone preservation in parts of the site, though it seems unlikely that this is the sole explanation. Some Iron Age sites such as Danebury and All Cannings Cross (Cunnington 1923, 74) have produced large numbers of bone needles, demonstrating that sewing (assumed to be predominantly for the production of clothing) was a common practice. If the relative lack of needles in Period 2 is genuine, it suggests that either much of the textile being produced during Period 2 was destined for sale as cloth, rather than being made into clothes on site, or that tailoring of garments was minimal. The increased incidence of needles in Period 3 may denote a change in emphasis, with greater production of finished clothing on site. This may have coincided with a general reduction in the amount of cloth being made, since the deposition of spindlewhorls drops markedly in Period 3 (Figure 532).

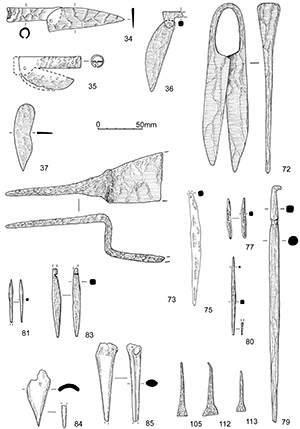

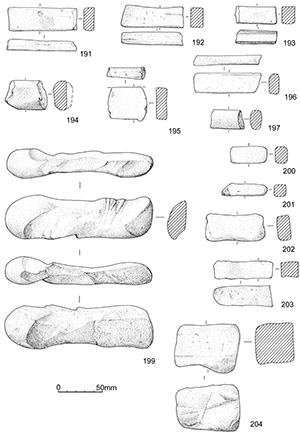

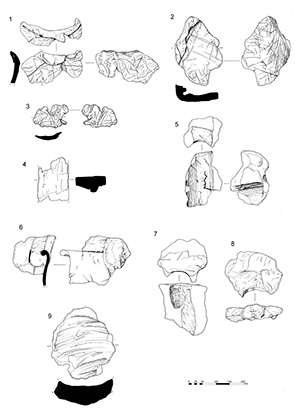

The six woolcomb fragments from the site form one of the largest assemblages of such objects from the country, although only two are reasonably complete. The use and typology of woolcombs is discussed by Manning (1976, 33) and Wild (1970a, 24-6). There are two main forms, the 'East Anglian' type, which is single ended with a slot in the other end, and a double-ended type, which is the form found on the continent as well. The end teeth on this type are often inserted, as with SF3492. Elsewhere in Essex, double-ended combs have been found at Dunmow (Major 1997, 86, no. 41), Kelvedon (unpublished) and Great Chesterford (Manning 1976, 34, D3).

Most of the woolcombs from Elms Farm are too incomplete to be certain of the form, though SF3492, with its inserted end tooth, is probably double-ended. The majority of the woolcombs known from Essex are of this type, which is normally about 90-110mm wide. SF5595, which appears to have its full width present, is a mere 40mm wide, and is single-ended. It has splayed teeth, a feature shared by SF1362. It is small enough to be perhaps thought of as a miniature, but is not the only woolcomb from Essex of this size. There is an example from Dunmow Temple a mere 37mm wide, also with splayed teeth (possibly single, rather than double-ended: Wickenden 1988, 56, no. 14), from a late 2nd-early 3rd century context, and a second from close to Chelmsford Temple (Wickenden 1992, fig. 42.1) a mere 26mm wide, from a late 1st-early 2nd century context. Wickenden suggests that this should be regarded as a new type, which seems reasonable, and which might be termed the 'Essex' type. A further example cited by Wickenden, from the vicinity of Harlow Temple (unpublished, HMB 6739) appears from the drawing to be a double-ended comb, as it has two inserted end teeth.

The occurrence of 'miniature' woolcombs close to temple sites is somewhat suggestive of ritual connections, although none of the examples came from contexts that could be seen as ritual deposits. The two dated examples are early to mid-Roman; the Elms Farm miniature is, unfortunately, the only woolcomb from the site not from a dated context. SF1362, which may be of this type, is from an Early Roman context, as are all the other fragments from the site bar one (SF5373, Period 5-6).

Only Areas E, F and I produced woolcombs (these are adjoining areas lying to the west of Road 1), suggesting that this area may have been particularly associated with primary wool processing. The distribution of the early Roman spindlewhorls and loomweights is somewhat different as both occur predominantly in the southern zone of the site (Figures 533 and 534). One can speculate that spinning and weaving was taking place in the latter zone.

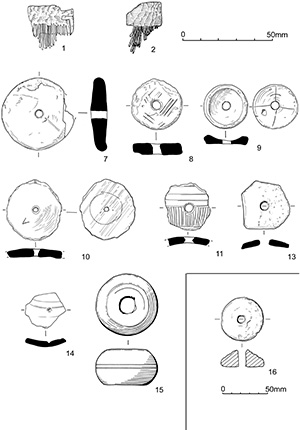

1. Woolcomb fragment. The X-ray shows clearly that the teeth were inserted, as was the extant end tooth. An angled notch on the same edge is probably the seating for a missing inserted tooth at the other end. Surviving W. 51mm, L. 50mm. SF3492, Fill 10319, Unknown feature 10322, Area F, Period 3

2. Woolcomb fragment. The plate appears to be the full width, although very narrow for a woolcomb. The teeth are splayed, and damaged. W. 40mm, surviving plate L. 27mm, max. surviving teeth L. 32mm. SF5595, Cleaning layer 13316, Area I, not dated

3. Not illustrated. Woolcomb fragment, with slightly splayed teeth, and a small part of the plate. The full width is not present. A second small fragment is probably part of the same object, but is very mineralised. 33x30mm. SF1362, Fill 8094, Well 8188, Group 788, Area E, Period 3

4. Not illustrated. Three joining fragments of a woolcomb (old breaks) with mineralised wood on the surface. Only teeth are present. The piece is probably from the edge of a comb with unsplayed teeth, although there is no thickened side piece. L. 97mm, Th. 6mm. Fill 8094, Well 8188, Group 788, Area E, Period 3

5. Not illustrated. Woolcomb fragment, with teeth at one end. Not enough survives to ascertain the form, or whether it had inserted side teeth. The width may be complete. Max. surviving tooth L. 53mm, W. 42mm. SF6465, Fill 13891, Ditch 18204, Group 593, Area I, Period 3A

6. Not illustrated. Woolcomb fragment. The broken teeth are unsplayed. One edge of the handle may be present. 60x30mm. SF5373, Layer 10514, Group 838, Area F, Period 5-6

Cite this as: Tyrrell, R. 2015, Spindlewhorls , in M. Atkinson and S.J. Preston Heybridge: A Late Iron Age and Roman Settlement, Excavations at Elms Farm 1993-5, Internet Archaeology 40. http://dx.doi.org/10.11141/ia.40.1.tyrrell4

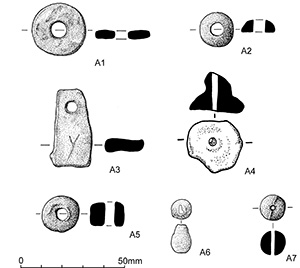

The site produced eighty-four spindlewhorls, eighty-two ceramic, one made from septaria and another example in shale, ranging in weight from 8g to 132g. There is little difficulty in accurately identifying the purpose-made spindlewhorls whether in ceramic or any other material, but those made from reused sherds of pottery are more problematic. In addition, three decorated lead weights, Type A2, Figure 524) may be whorls. This is, however, doubtful as they are somewhat small, with small perforations (3-5mm diam.). The small hole would only allow the use of a rather thin, and consequently flimsy, spindle.

Barber (1991, 51) discusses the size of spindlewhorls in the Mediterranean world. She quotes Middle Eastern Islamic examples of 8mm in diameter as being the smallest then recorded and the diameter of the hole for the spindle-shaft ranged from 3 to 8mm. A thin spindle could easily be wedged into an over-large hole with a twist of yarn. She recorded a maximum weight of 140-150g in those she studied and underlines the fact that the weight is an important feature of these objects. Heavier whorls are needed to spin longer staple, stronger fibres and the smaller disc will spin faster and all this will affect the thread produced. The wide weight range of the Elms Farm examples may suggest that a variety of fibres were being worked on the site.

A number of objects, classified on-site as spindlewhorls, were returned to the pottery assemblage as merely sherds from pots that happened to have holes. Some reused pottery discs could also be considered here, as they may be undrilled whorls, but will be discussed with the other pottery discs. The author thinks that it is more likely that a prospective whorl-sherd would be drilled before grinding the edge to shape. It would seem a waste to edge-finish a sherd, which might subsequently break. The discs are possibly counters.

The Elms Farm spindlewhorls can be divided into four types by shape. Four were purpose-made, two of which are ceramic in a well-fired, grog-tempered fabric, with one example in shale, and a rather abraded septaria whorl. Eleven of the reused pot sherd whorls had ground, smooth edges, including a samian one. Six more had been carefully trimmed prior to grinding, including a sherd of amphora, and one had been particularly well trimmed. The remaining sixty-two sherd-made whorls have only been roughly finished.

Crummy (1983, 67) gives specifications for the spindlewhorls from Colchester. She suggests that the whorl should be of an even thickness and have smooth sides, features necessary to ensure that the whorl spins smoothly and produces an even thread. While the trimmed discs would function reasonably well as whorls, it is hard to see the roughly edged ones spinning efficiently. It is suggested that these are unfinished objects awaiting trimming. Two of the rough discs have depressions resulting from unfinished drilling; as already stated, trimming would need to be done after successful drilling.

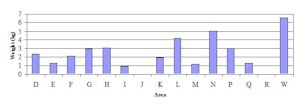

Period 2 contexts produced 54% of the whorls, and another 14% come from features in Period 3 (Figure 536). It is also possible that those in many of the later contexts are earlier ones redeposited. In addition to this early slant to the assemblage, all but three of the pottery sherd whorls are made from Period 2 fabrics. The quantities of apparently unfinished whorls suggest that these objects were being made on site, either simply to meet the needs of the settlement or as trading items. A study of the spatial distribution puts the focus of this activity in Southern Zone of the site (Tables 109 and 110).

| Area | u/s | D | E | F | G | H | I | J | K | L | M | N | P | Q | R | W |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No. | 2 | 5 | 2 | 9 | 6 | 11 | 1 | 4 | 8 | 12 | 5 | 13 | 3 | - | 1 | 2 |

| Zones | Northern | Central | Southern | Hinterland | ||||||||||||

| No. | 22 | 16 | 41 | 3 | ||||||||||||

| Area | u/s | D | E | F | G | H | I | J | K | L | M | N | P | Q | R | W |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| No. | 1 | 2 | 1 | 5 | 4 | 9 | - | 3 | 7 | 12 | 5 | 11 | 3 | - | - | 2 |

| Zones | Northern | Central | Southern | Hinterland | ||||||||||||

| No. | 12 | 12 | 38 | 2 | ||||||||||||

The author can only speculate regarding what happens to spinning in the later Roman period at Elms Farm. Only three whorls, one in fine greyware, one made from septaria and the third from shale, come from the later and latest Roman Periods 5 and 5-6. The greyware is a Roman fabric that may be contemporary with its context. Whorls may also have been made from materials that leave no evidence in the archaeological record, like wood, or possibly the previously flourishing craft of spinning may have declined.

The unillustrated spindlewhorls are listed in the archive catalogue.

7. Purpose-made, disc-shaped whorl, slightly thinner at the edges (Figure 535). Pottery fabric: GROG. Wt 102g. SF3530, Fill 5151, Pit 13366, Group 409, Area J, Period 3

8. A reused pot sherd with ground edges. The parallel grooves on one of the surfaces were probably on the potsherd prior to reuse. Pottery fabric: GROGC. Wt 50g. SF7832, 23009, Pit 23005, Group 236, Area N, Period 2

9. A reused pot sherd whorl, made from a base with the broken edges of the pot walls ground smooth. Four lines have been roughly scratched from the hole radiating outward. Pottery fabric: BSW. Wt 22g. SF7676, Machining layer 11000

10. Reused pot sherd, with trimmed edges and traces of a roughly inscribed circle concentric to the hole. Pottery fabric: GROG. Wt 48g. SF7300, 16029, Pit 16037, Group 200, Area H, Period 2B

11. A reused pot sherd whorl, with roughed-out edges. Pottery fabric: GROG. Wt 22g. SF7394, 14519, Pit 14561, Group 262, Area L, Period 2B

12. A reused amphora sherd whorl, with trimmed edges. Pottery fabric: AITAL. Wt 48g. SF6089, 13553, Layer 13553, Group 102, Area I, Period 2B

13. A reused pot sherd whorl, with roughed-out edges. Pottery fabric: GROG. Wt 26g. SF2850, 9163, Gully 9865, Group 2083, Area D, Period 2-3

14. A reused pot sherd whorl, with roughed-out edges and a partially drilled hole. Pottery fabric: GRS. Wt 13g. 8000, Machining layer 8000, Area E, unstratified

15. Shale. Sub-globular whorl, flat top and bottom, with two incised lines around the mid-point. A similar object from Segontium is cited as a possible sword pommel (Allason-Jones 1993, 206, no. 496), though this seems an unlikely interpretation at Elms Farm. Most shale spindlewhorls come from Late Roman contexts, as does this one. Wt 16g. Diam. 35mm, Ht 19mm. SF4638, Fill 10405, Ditch 10538, Group 838, Area F, Period 5-6

16. Septaria. A purpose-made, domed whorl. Wt 30g. SF5771, Pit 10910, Group 676, Area N, Period 5

Cite this as: Tyrrell, R. 2015, Ceramic loomweights, in M. Atkinson and S.J. Preston Heybridge: A Late Iron Age and Roman Settlement, Excavations at Elms Farm 1993-5, Internet Archaeology 40. http://dx.doi.org/10.11141/ia.40.1.tyrrell3

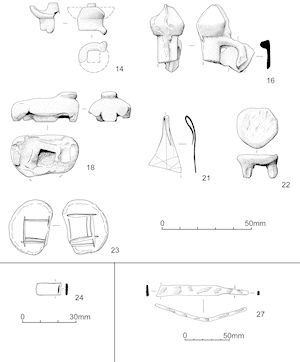

The excavations produced 443 fragments from 142 triangular loomweights, weighing 36.5kg. In addition, there were two pieces of a Bronze Age cylindrical loomweight from a prehistoric post-hole (13440) in Area J (described in the report on the prehistoric activity at Elms Farm: Tyrrell 2001, 67). Two truncated pyramidal objects (nos 24 and 25), which may be weights, but not necessarily loomweights, are included here.

There are also a number of baked clay blocks of uncertain function from the site. These are not discussed here because they do not have any holes, but could possibly have been tied to the warp threads of a loom.

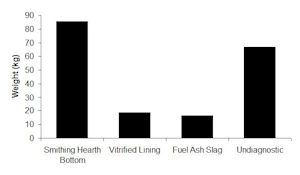

Triangular loomweights are a typically Iron Age form, used on warp-weighted looms, and thought to pass out of use in the 1st century AD (Major 1982, 111). By weight, 56% of the Elms Farm examples came from mid-1st century BC to mid-1st century AD contexts (Figure 537). However, a group of loomweight fragments was found at Ardleigh, Essex (Major 1999c, 157), dumped in a disused Roman kiln. Assuming from their condition that these were not redeposited, the author surmised that the vertical loom was still in use in the early 2nd century AD. A close study of the pottery dates of the twenty-three Period 3 weight fragments from Elms Farm shows that only three of these were from contexts that clearly dated to later than the early 2nd century. The dating of the other contexts is less reliable in that while they may continue into the early 2nd century, they actually start earlier. So while triangular weights may continue in use later than has been usually accepted, the evidence from this site is insufficient to resolve the case. Another lesser peak of quantity in Period 6, 23% of the total by weight, is probably a result of redeposition owing to later disturbance.

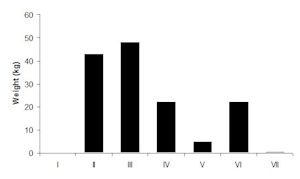

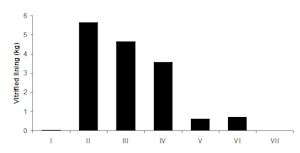

Figure 538 gives the quantities of loomweights in each area and shows a peak in the material from Area W. This results from the good state of preservation of the material from Area W, in that the group consists of largish fragments of eleven weights; the lesser peak in Area N represents pieces of twenty weights, but in smaller fragments. The peaks of quantities in Areas L and N may be the result of the density of pitting in those areas during Period 2. The differences between the other areas are less pronounced, with the exception of Areas R and J. The presence of as little as 32g of material in Area J underlines the non-domestic nature of the temple precinct. The complete lack of fragments from Area R may be because most of the activity in this area of the site occurred after Period 2.

The loomweights were examined macroscopically and divided into three fabrics according to the frequency and nature of the inclusions. Fabrics A to E were used in the classification of the daub.

Fabric F A poorly mixed fabric with sand, irregular fragments of quartz and flint pebbles. The colour is brown through to reddish at the core. There is 29641g of this fabric.

Fabric G This fabric had very little tempering, a small amount of sand and vegetable matter. The clay was evenly brown in colour, darkening slightly at the core. There is 3711g of this fabric.

Fabric H A similar fabric to F but with smaller inclusions and some vegetable tempering. The surfaces have dense vegetable impressions. There is 3209g of this fabric.

The majority of the loomweights (123) were in Fabric F, with fourteen in Fabric G and five in Fabric H. The significance of the fabrics is not clear. They do not appear to correlate with period, deposition or shape. Weights with saddle-shaped tops, for instance, were made in all three fabrics.

Although the variation in size of the loomweights from Slough House Farm, Essex, was thought to relate to a difference in period (Major 1998d, 161), this does not appear to be the case with the Elms Farm assemblage.

Because of the hand-made nature of objects they vary in size and style. Although none of the almost complete examples had all their corners intact, it was possible to measure some of the complete side lengths. Details of the range of dimensions present are given in Table 111.

| Average | Range | No. of examples | |

|---|---|---|---|

| Length of side | 137mm | 110-165mm | 7 |

| Thickness | 72mm | 54-100mm | 25 |

| Weight (all weights over 1kg) | 1338g | Max. 1800g | 8 |

| Hole diameter | 12mm | 7-20mm | 61 |

It is assumed that they would have had a suspension hole across at least one corner and possibly through all three corners. However, only three weights are complete enough to be certain that three holes were present. Indeed, one other substantial weight, from spread 75 in Area W, appears to have only one hole, but eleven separate fragments have at least two holes. In all cases the holes were made when the clay of the weight was soft. The holes through twelve of the weights were positioned close to the corners, but in five more the holes were positioned nearer to the centre of the side of the weight. There does not seem to be any pattern to this feature, so perhaps this positioning always varies but is only apparent in a large group.

Eight of the loomweight fragments have a saddle-shaped apex. This feature has been noted at other sites. At West Stow, Suffolk (West 1990, 68), the saddle-topped triangular loomweight found was from a 1st-century BC to 1st-century AD context, whereas the plain examples were found in 3rd to 1st-century BC contexts. The Elms Farm plain loomweight tops are all from Period 2 contexts, while the saddle-topped examples were found in Periods 2, 3, 4 and 5. The fragments in the later contexts were found with residual pottery, which suggests that they may be redeposited earlier weights. However, there is a slight suggestion here that the saddle-shaped apices could be a late feature.

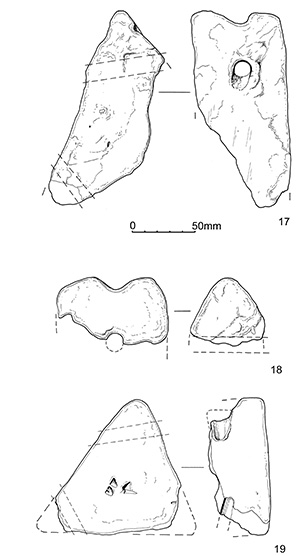

While no two weights are exactly the same in shape because of the hand-made nature of these objects, some stand out of the assemblage as different in character. One weight (no. 17), from pit 23124 in Area N, is very crudely shaped, with unusually sharply moulded edges and a rather angular saddle top. Two of the loomweights, from 11091 and 14580, are more carefully moulded than the rest of the assemblage, having completely flat faces and straight edges. These weights, like the majority of the assemblage, are from late 1st-century BC to early 1st-century AD contexts.

One of the weights (no. 19) from a pit in Area N has been marked with a cluster of three small irregular impressions poked into the surviving face of the weight. Whether this is some form of maker's mark or merely accidental is difficult to be certain. There is a Late Iron Age weight from Rivenhall (Rodwell and Rodwell 1993, 59) with a line of small dots, made with the teeth of a comb, but this too could be accident rather than design. The early to mid-1st century AD pottery, found with the Elms Farm weight, means it may be slightly later than the one from Rivenhall but fits into the general period of loomweight deposition. Although the pit in question (11092) is phased as Period 3, the weight came from the earliest fill.

The loomweights were examined for signs of wear that might indicate the way in which they were used. The weights from Burgh, Suffolk (Martin 1988, 63) were considered to have wear-patterns around the holes that indicated they were hung point downwards. Despite the large quantities of material, little evidence of wear of this type could be detected on the Elms Farm weights. However, the weight from post-hole 8790 in Area P (no. 21) has short grooves on one side of the apex. If a cord were tied through the holes, and the weight hung from this with the point down, this seems to be where the weight would be chafed. It is possible that the grooves in the saddle-shaped apices were designed to keep a tie round the edge of the weight in place as it pointed downwards.

Two baked clay weights (nos 24 and 25) are truncated pyramids, with a single hole through the narrower end. They are both well moulded, with one slightly larger than the other, somewhat lop-sided, and small compared to the triangular weights. A complete and very similar object was found with Late Iron Age pottery in a pit at Cressing Temple, Essex (Tyrrell in prep). If they are loomweights, rather than weights used for some other purpose, they were possibly for weaving either fine textiles or perhaps braid. There are few parallels from Britain. When describing the Dragonby example (Elsdon and Barford 1996, 330, no. 2), which is also very similar in shape and date, Barford suggests that these 'mini' weights could have been used alongside the larger ones to allow the weaving of stripes or tartans.

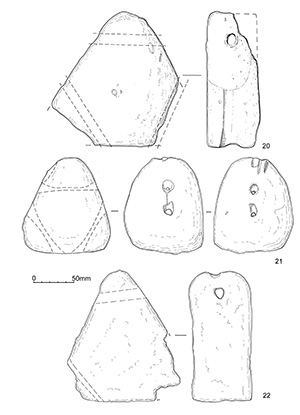

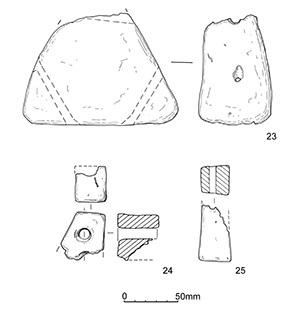

17. Triangular loomweight, crudely made, but with sharply moulded edges and a saddle top, Fabric G. SF4829, Fill 23056, Pit 23124, Group 236, Area N, Period 2B

18. A rounded triangular loomweight with a saddle top, Fabric F. SF7865, Fill 11306, Pit 11316, Group 227, Area N, Period 2A

19. A smooth well-moulded triangular loomweight with a possible decoration of three small holes, Fabric G. SF7650, Fill 11091, Pit 11092, Group 667, Area N, Period 3

20. A plain-topped triangular loomweight, Fabric F. SF218, Fill 81, unknown feature, Area W, Period 6?

21. A plain-topped triangular loomweight with bulging sides and grooves on the apices, Fabric F. SF6309, Fill 8789, Post-hole 8790, Group 1272, Area P, not phased

22. A well-moulded triangular loomweight, Fabric H. SF6233, Fill 14580, Pit 14579, Group 264, Area L, Period 2B

23. A plain-topped triangular loomweight, Fabric F. SF2219, Fill 10147, Pit 10146, Group 297, Area F, Period 2

24. The upper section of a truncated, pyramidal object with a hole just below the top, possibly a loomweight Fabric G. SF8406, Fill 5808, Group 398, Area J, Period 3B

25. The lower portion of a truncated pyramidal object, damaged top, possibly a loomweight Fabric G. SF8407, Fill 23056, Pit 23124, Group 236, Area N, Period 2B

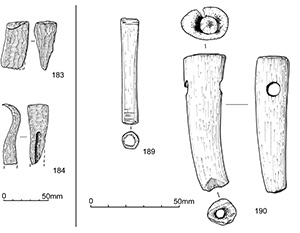

This tool is similar to a number of metapodial tools found at Dragonby (Taylor and May 1996, 353-7), mostly in Late Iron Age, and some Early Roman, contexts. The Elms Farm example is from a mid-Roman pit, and may be redeposited. Although the Lincolnshire examples have a variety of wear patterns, it was thought most likely that they functioned as weaving bobbins.

26. Not illustrated. A metapodial tool, perforated along the length and through the shaft, but broken off at the central hole. No signs of wear could be determined since the object is so fragmentary. L. 73mm, Diam. 16mm. SF5702, Fill 4925, Pit 4943, Group 739, Area K, Period 4

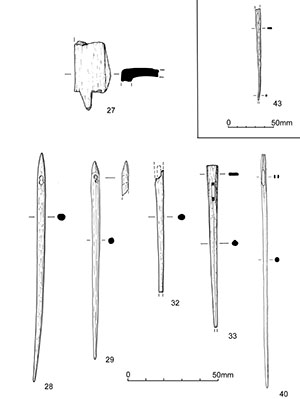

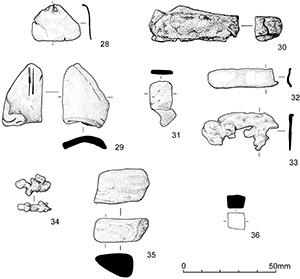

Bone weaving combs are a distinctive Iron Age form (Hodder and Hedges 1977), and this example must be residual in its context. Although common in some parts of the country, particularly the west of England, they are very rare in Essex. There is a more complete example from Great Dunmow (Major 1997, 86), and another from North Shoebury (Brown 1995, 127).

27. Fragment from a weaving comb, with one surviving tooth. Scorched and partly carbonised. The edge is unfinished rather than rounded, as it would normally be, but this may the result of flaking due to the burning rather than to the artefact being unfinished. L. 38mm, W. 20mm. Fill 14564, Stoke-hole 14565, Group 5017, Area L, Period 5

The bone and metal needles have been classified using the Colchester type series (Crummy 1983, 65-7).

Seven bone needles were recovered (Figure 542). Types 1, with pointed heads, and 2, with flat heads, were noted. At Colchester, both types had wide date ranges within the Roman period. The Type 1 needles from Elms Farm all come from late 1st to mid-2nd century contexts, with the exception of one (SF396) that is probably residual in a later midden context. The Elms Farm Type 2 needles are from mid- to Late Roman features.

Crummy (1983, 65) experimented with a 6mm diameter needle sewing through cloth of seven warp threads per 10mm. She found that the thick needle did not leave large holes because each new stitch closed up the previous holes, and that this was particularly so for the needles with spatulate heads. She also suggests that for finer, closely woven cloth a thinner needle is necessary.

28. Figure-of-eight eye. Complete. SF 4187, Fill 4978, Pit 4979, Group 755, Area K, Period 3

29. Figure-of-eight eye. Complete. SF6103, Fill 13793, Trench 18697, Group 613, Area I, Period 3B

30. Not illustrated. Figure-of-eight eye. Shaft broken off. L. 58mm, Diam. 4mm. SF5291, Fill 4081, Pit 4080, Group 62, Area K, Period 2

31. Not illustrated. Figure-of-eight eye. Part of head with most of shaft broken off below the eye. L. 25mm, T. 2mm. SF396, Layer 13211, Group 640, Area I, Period 4

32. Rectangular eye. Part of head and tip broken off. SF6836, Fill 4011, Pit 4083, Group 739, Area K, Period 4

33. Rectangular eye, point broken off. SF5949, Fill 15280, Pit 15271, Group 468, Area M, Period 4

34. Not illustrated. Rectangular eye. Part of head and tip broken off. L. 24mm, Diam. 3mm. SF2018, Cleaning layer 5307, Area J, Period 5-6

There were seven copper-alloy needles, all Crummy's Type 3 (Figure 542). All the Colchester Type 3 needles were from 3rd and 4th-century contexts, and this was postulated to be the general date for the type. However, both of the stratified examples from Elms Farm came from Period 3 contexts (Early Roman). A similar situation was noted at Castleford (Cool 1998, 92), where all five Type 3 needles came from Antonine or earlier contexts. It is therefore reasonable to suggest that the type was in use throughout the Roman period, and that the Elms Farm examples are not intrusive.

35. Not illustrated. Broken across the bottom of the eye and bent. L. 85mm. SF9513, 3999, Spoil-heap

36. Not illustrated. Complete, with a slight curve. There is a groove above and below the eye. Good condition. L. 125mm, Eye L. 9mm, max. W. 3mm. SF674, Machining layer 4000, Area A, unstratified

37. Not illustrated. Complete but in two pieces, and with one side of the eye missing. Fair condition, surface obscured by earth. L. 101mm. SF1153, Fill 4243, Pit 4211, Group 756, Area K, Period 3

38. Not illustrated. Head damaged, almost complete, tip bent. It has short, shallow grooves above and below the eye, on one face only. Condition fair, surface flaked in places. L. 79mm. SF1390, Fill 5146, Pit 5147, Group 409, Area J, Period 3

39. Not illustrated. Point missing, bent. L. 86mm. SF1992, Unknown context 5385, Area J, not dated

40. Complete and in good condition but cracked across the eye. SF6104, Fill 13822, Trench 13756, Group 613, Area I, Period 3B

41. Not illustrated. Broken across the base of the eye, with the point missing. L. 100mm. SF7278, Cleaning layer 18737, Area J, not phased

There were ten iron needle fragments (Figure 542), mostly the standard Crummy Type 3. However, there were also one definite and two possible examples of Crummy Type 2a, which has a spatulate head, and is rare in iron.

Not all objects resembling Type 2a needles have been identified as needles. Manning (1985a, 86, N9) illustrates an example from London as a stylus, while noting that the hole in the eraser is probably intentional. The criterion for Crummy's Type 2 needle is a flat spatulate head; the material can be copper alloy or bone. While most examples have fairly narrow heads, and are clearly needles, some in copper alloy have broad, flared heads, similar to stylus erasers, with the eye set at the base. The shafts are mostly thin compared to definite styli, as with the Elms Farm and London examples in iron, and it seems more likely that they are genuinely needles rather than an unusual form of stylus. Indeed, they may be more common in iron than is apparent, since without the benefit of X-rays they are indistinguishable from styli. The type in copper alloy is predominantly 1st-2nd century AD, as is the illustrated example, with a second example from a latest Roman ditch. The third example (SF4148) is from a pre-Roman pit [4786], possibly back-filled by the end of the 1st century BC. While it could be intrusive, it may be a genuine Late Iron Age artefact. Iron Age iron needles are rare; there are, for example, none in the finds reports for Danebury, which had over fifty bone needles. Certainly, bone seems to be the favoured material for Iron Age needles, and SF4148 may be copying a form primarily found in bone. The Danebury Class 4 needles have relatively wide, flat heads, corresponding broadly to Crummy's Type 2a, but appearing less well finished (Sellwood 1984, 380). One of the illustrated examples (fig. 7.32:3.83) has a head as broad as SF4148, and it may be that the Roman type has an Iron Age ancestry.

In addition to the definite needles, some fragments of wire could be needle shafts or points (included in category 20). The most likely needle fragments are from 5610 (undated cleaning layer); 7598 (undated collapse); 10000 (Period 4 pit); 10071 (Period 3B gully); 10621 (Period 4 pit); 13419 (Period 2-6 layer); and 20031 (Period 2 pit).

42. Not illustrated. Four fragments (broken in antiquity) of a Type 2a needle, point missing. Head W. 9mm, surviving L. c. 64mm. SF4148, Fill 4874, Pit 4786, Group 276, Area K, Period 2

43. The top of the head and the point are missing, both old breaks. In two pieces, broken in antiquity. L. 101mm. Fill 13387, Pit 18019, Group 3024, Period 3

44. Not illustrated. Needle fragment, with an oval hole. A second, spatulate, fragment is probably the head of the needle, which would thus be a Crummy Type 2a. L. 41mm, head W. 10mm. Fill 5376, Ditch 5359, Group 443, Area J, Period 6

45. Not illustrated. Fine needle, broken across the eye. The point is probably missing. The slit is a long rectangle, with the head bulging slightly round it, comparable to e.g. Manning D27-32. The metal is so thin at the eye that it barely shows up on the X-ray, demonstrating the difficulty of identifying needles of this fineness, unless complete. L. 44mm, Diam. 1mm. SF2296, Cleaning layer 5603, Area I, not phased

46. Not illustrated. The details of the eye are unclear, but it is probably fairly long, with little swelling of the head. L. 84mm, diam. 1.5mm. SF4148, Pit 4786, Group 276, Area K, Period 2-3

47. Not illustrated. Both ends missing, broken across the bottom of the eye. There is a groove below the eye, possibly on one face only. This would have been a fairly small needle. L. 23mm. SF2024, Cleaning layer 5307, Area J, Period 5-6

48. Not illustrated. A small, fine needle, point present but broken across the eye. L. 31mm. SF4755, Layer 5907, Group 601, Area I, Period 3B

49. Not illustrated. Point missing, broken across the bottom of the eye. Slightly bent. L. 64mm. SF7417, Pit 15757, Group 900, Area M, Period 3

50. Not illustrated. Pointed wire, circular section, tip bent. This is probably a needle, broken at the base of the eye (a fresh break); there is a slight suggestion of the beginning of an eye on the X-ray. L. 52mm, diam. 1.5mm. 7115, Pit 7114, Group 885, Area G, Period 6

51. Not illustrated. Head fragment. Hole L. 3mm, L. 26mm, Diam. 1mm. 5393, Pit 5394, Group 432, Area J, Period 5

The iron tools from Elms Farm form a large, varied and important group. Many are, unfortunately, incomplete, and some difficulties were encountered categorising some tools. The tips, in particular, were sometimes damaged, making objects such as small punches and awls difficult to distinguish from one another. The number of objects in this function category should undoubtedly be even larger, since any small, pointed bar fragments were classified as nail shafts unless there was any indication to the contrary. Very few bar fragments were cleaned, so it was not possible to distinguish between those with square sections, which were more likely to be nails (or could have been parts of tool tangs) and those with circular sections, which were probably not nails.

The following are iron unless otherwise specified.

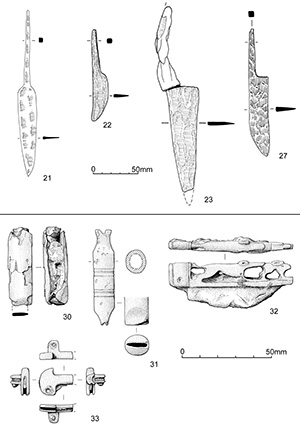

Thirty-nine iron knives were identified. In addition, there were another thirty-one single-edged tool fragments that could be parts of knives, or could be from other types of blade, and a copper-alloy handle fragment. Few of the knives were cleaned, and some drawings therefore lack sections.

The knives have been classified according to the form of their handle, or tang shape where the handle is missing. The terms scale tang and whittle tang have been adopted for convenience; they are in general use in medieval finds reports, though rarely used in Roman ones, but the forms are the same.

Scale tang knives have broad, flat tangs to which the bone or wood handle plates were riveted. They are relatively rare forms in both the Late Iron Age and the Roman period. In Manning's typology (1985a, 108ff) most of the forms with scale tangs are Early Roman types. There were three definite and two probable examples from Elms Farm, one from Period 2, two from Period 4, and two undated.

Knives with integral handles are also largely Early Roman. Many of the forms are distinctive in shape, with examples from different sites closely resembling each other, and it is likely that these were not locally made. There are four from the site, all of different types. Two are standard Early Roman types, but two are more unusual. One (SF6454) is a variant of Manning's type 8, which he cites as a rare Early Roman form. The other (SF3999, from a mid-later Roman context) has a broad, flat handle resembling a scale tang, but with no rivet holes, and it does not conform to any of Manning's knife types.

There are three socketed knives, one of which is possibly a small cleaver, from a Late Iron Age context.

Whittle tang knives, the most common form at Elms Farm with sixteen examples, occur throughout the life of the site, and most require no comment. The type would have had a one-piece handle, which has survived on only one knife. The group includes a small knife with an unusually shaped blade (SF1954), which may have been used for a specific purpose. There is also an unfinished knife, abandoned during the formation of the tang.

The two copper-alloy knife handles found are probably both the same type, though one is damaged and in poor condition. This form of handle is discussed in Greep (1982), where he calls it the 'London Type', although found at other sites. Most examples are made of bone, and of the twenty examples listed by Greep, only one (from Vindonissa) is made of copper alloy, so these examples are very rare finds. Local examples in bone include several from Colchester (Crummy 1983, 107-9). Their date is Claudian-Neronian to early Flavian.

Finally, there are five folding knives. One is a well-known, though not very common, standard form, with a copper-alloy handle depicting a dog and hare. It belongs to Lloyd-Morgan's Group II, with parallels cited by her from London, Cirencester, Duston (Northants), Hadstock, Chesters Museum, Corinium Museum, and Richborough (in Garrard 1995, 1035, no. 452), and there is a further example from Cottenham, Cambs (Taylor 1987, 8, no. 23). The second is a fragment from the copper-alloy handle of an unusual knife, apparently with a pivoting blade, and possibly incorporating a second blade or other implement. Only one parallel has been identified, from Wroxeter (Bushe-Fox 1914, 14, no. 19). Neither example is dated.

The other three are entirely of iron, two with tubular sockets and one with a tang. The tubular form in itself is not very rare, but is normally made from copper alloy, with an iron blade, and is commonly described as a razor handle. There are two examples from Exeter (Allason-Jones 1991, 249, nos 52 and 53) from contexts dated c. 275 and late 3rd-4th century; three from Chichester (Down 1978, 293, no. 27; Down 1989, fig. 27.2.25 and 28.3.31), all from post-Roman contexts; and an unstratified example from Brancaster (Sparey Green and Hinchliffe 1985, fig. 33, no. 63). One of the Chichester examples retains its horn handle, and some have decoration on the copper-alloy ferrule, walked scorper at Chichester and hatched at Brancaster. Parallels made entirely from iron are very rare; there is one from Lowbury Hill, Berkshire, which is very similar, though with a slightly different shape to the blade (Atkinson 1916, 50, no. 20). Atkinson notes a further folding knife from Woodcuts. Another possible example, from Richborough (Henderson 1949, 132, no. 145 and pl. XXXIX), is an object that appears to be a closed folding knife, lacking the pivot end. The slightly tapering ferrule is stated to be made of iron, but coated with bronze. It is possible that the socket is in fact copper alloy, as with the other examples, the apparent iron component being the result of corrosion from the blade. The third folding knife from Elms Farm, with a whittle tang to the handle, appears unique, though its form seems related to the socketed examples. The Lowbury Hill knife has a tang of sorts, very short and flat, though on the blade rather than the handle.

Both the socketed folding knives may have come from the same pit (14099), as although one was from a cleaning layer, part of it came from a spot directly over the pit. They could therefore be a true pair. The presence of three very unusual folding knives on a single site suggests that they may have been made at Elms Farm, in imitation of the copper-alloy version. This is further supported by a possible unfinished folding knife blade from another feature (SF3567).

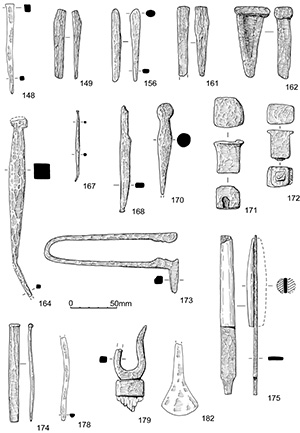

1. Knife with a relatively narrow scale tang set centrally, with very decayed organic matter on the handle and blade. There is a rivet through the tang, in totally corroded grey-green metal, probably copper alloy (Vanessa Fell). L. 151mm, blade W. 20mm. SF7007, Fill 11487, Pit 11785, Group 1242, Area N, Period 2

2. Not illustrated. Knife blade fragment, complete as buried, but with both ends missing. Parallel-sided blade with a scale tang. Blade L. 38mm, W. 20mm. Tang L. 18mm, W. 9mm. SF8039, Fill 4844, Pit 4913, Group 4016, Area K, Period 4

3. Not illustrated. Probable knife fragment, with a parallel-sided blade and a scale tang. Both ends are missing. L. 71mm, max. blade W. 22mm, tang W. 16mm. SF1827, Fill 10000, Pit 10062, Group 811, Area E, Period 4

4. Not illustrated. Scale tang, probably part of a knife handle, both ends broken. It has two iron rivets protruding 3-4mm either side. There are traces of organic matter on the surface. Vanessa Fell notes that there is insufficient surviving for an identification, but the striations suggest wood or horn. L. 46mm, section 16x4mm. SF3491, Fill 10320, Pit 10321, Group 828, Area F, Period 4

5. Knife blade in three pieces, straight-backed with an (incomplete?) perforated scale tang. L. 109mm, W.21mm. Possibly a residual Late Iron Age/Early Roman knife. SF2301, Cleaning layer 5603, Area I, not phased

6. Not illustrated. Knife fragment; three joining fragments of a straight-backed, almost parallel-sided blade with a scale tang, broken at both ends. Blade L. 65mm, W. 13mm; tang L. 25mm, W. 8mm. SF7837, Cleaning layer 23002, Area N, not phased

7. Knife, complete but in three pieces, with a scale tang, and a broken suspension loop. Straight cutting edge, with the back sharply angled down to the point. There is no obvious break between the blade and tang, which are the same width, but the tang must be relatively short, as an edge is still visible in the break nearest the loop. This is a knife of Manning's type 1a (1985a, 109), which he cites as an early type, commonest in the 1st century AD. L. 135mm, W. 15mm. SF3294, Fill 9488, Ditch 9496, Group 150, Area D, Period 2B

8. Variant of Manning type 8. The tip of the blade is missing but the rod handle is probably complete. It is sturdy, and non-tapering, with an oval or rectangular section, and two circumferential grooves at the end. There is mineralised wood on the tang, but it is unlikely to be part of the handle as its orientation is wrong. L. 125mm, tang section c. 9x7mm. SF6454, Fill 13800, Pit 13809, Group 397, Area J, Period 3

9. Knife, Manning type 4. This type has a narrow, parallel-sided blade with an integral handle with an end loop. Manning considered that they were probably razors, or scalpels (Manning 1985a, 110). Most of the end loop is missing, and most of the blade. The handle has a rectangular section. SF6739, Layer 13576, Group 600, Area I, Period 3B

10. Knife with a flat handle, terminating in a suspension loop. There are no rivet holes present. The edge of the loop may be thickened on the tang side. L. 186mm, max. W. 32mm W. of tang 16mm. SF3999, Fill 10362, Ditch 10538, Group 838, Area F, Period 5-6

11. Socketed small cleaver or knife, with mineralised wood in the socket. The back is angled down from the junction with the socket, a probable Early Roman feature in knives; for similar cleavers see Manning 1989, 123, type 6, although in the present case the handle would have been parallel to the blade. L. 166mm, max. blade W. 48mm. SF5797, Fill 11063, Ditch 11062, Group 145, Area N, Period 2

12. Small blade, resembling a miniature pruning hook with an open socket. The end of the socket is damaged, but the length may be complete. The tip of the hook is missing. Unlike pruning hooks, however, the convex (i.e. the outer) edge of the blade is the cutting edge, with a blunt internal edge. The shape of the blade is very similar to a post-medieval saddler's and harness maker's head knife (or heading knife) used for work such as cutting holes for buckle tongues, and which also has the cutting edge on the outside of the curve (Salaman 1986, 256 and fig. 9:7). L. 76mm. Fill 13844, Pit 13845, Group 611, Area I, Period 3

13. Not illustrated. Open socket, tapering to a thin, flat blade, broken where it begins to expand. The surviving part of the blade has no sharp edge. This is probably a knife, and probably Manning's type 22, which he notes as a rare form. Most examples are from London, although there are two from Baldock (Manning and Scott 1986, 155, nos 535-6). L. 93mm, max. W. of blade 15mm. SF2278, Fill 5536, Post-hole 5545, Group 435, Area J, Period 5

14. Socketed knife, with a slight constriction between the socket and the blade. The socket is open, and rather crudely made, with a single perforation. The point of the knife is rounded. There is mineralised wood in the socket, but too little survives for identification. L. 124mm, blade max. W. 21.5mm, socket max. W. 23mm. SF1939, Fill 4709, Pit 14127, Group 1167, Area K, not phased

15. Knife. A very small, thin, leaf-shaped blade, with a rectangular sectioned tang, set centrally. The tang was broken in antiquity. L. 59mm, max. W. 14mm. SF1941, Fill 4539, Pit 4698, Group 754, Area K, Period 2

16. A very small, roughly semi-circular, tanged blade. There are traces of a bone handle on the incomplete tang. Manning type 13. The type includes a number of small examples, but this is unusually small, verging on a miniature. The presence of a bone handle suggests that it is a functional object rather than a model, and it may have had a specialised function. Total L. 62mm, L. of blade 37mm, W. 19mm. SF6644, Fill 15515, Pit 15514, Group 696, Area M, Period 4

17. Not illustrated. Knife tang of constant rectangular section. Most of the blade was broken off in antiquity. L. 67mm, section 8x4mm. SF4157, Fill 4870. Pit 4913, Group 4016, Area K, Period 4

18. A small, almost semi-circular blade, with the end of the tang curled over. The object appears complete, and may be a specialised tool. L. 86mm, max. W. 25mm. SF1954, Layer 4689, Group 4019, Area K, Period 4-5

19. Small tanged knife with a straight back and a curved edge, point missing. The knife appears to be unfinished, with the tang not fully formed. The strip that formed the blank for the knife was slit at an angle to form the heel of the blade, and the tang then formed by rolling the strip over. However, this process was not completed, as the part of the tang at the blade end has not been hammered flat. The edge of the blade is chamfered on one face only. L. 85mm. Max. W. of blade 22mm. SF1813, Fill 4392, Pit 4429, Group 741, Area K, Period 5

20. Small tanged knife, point and end of tang missing. It has a straight back and a curved cutting edge, with the tang set centrally. L. 62mm, max. W. 16mm. The complete blade would have been c. 74mm long. SF7751, Fill 22051, Well 22210, Group 448, Area J, Period 6

21. Tanged knife, complete, with a spear-head shaped blade, edged on one side only. Manning type 16. L. 185mm, max. W. 19mm. Tang L. 85mm. SF6279, Cleaning layer 20007, Area L, Period 5-6

22. Knife blade with square-sectioned tang. It has a curved blade edge with the tip missing. L. 104mm, L. of tang 49mm, max. W. of blade 16mm. SF1936, Fill 4140, Pit 4139, Group 744, Area K, Period 6

23. Knife, Manning type 11a. The point of the triangular blade is missing. It has a straight tang in line with the back, set into a curved antler handle. Little of the surface survives, but it originally had a polygonal section, probably octagonal. L. 210mm, blade L. 120mm, blade W. 35mm, tang L. 38mm. SF4943, Fill 15006, Pit 15005, Group 701, Area M, Period 6

24. Not illustrated. The tang and a small part of the blade of a knife. The tang is in line with the back. The blade was broken in antiquity, and there is also modern damage to the edge, so that the width is incomplete. Overall L. 60mm, tang L. 37mm, blade W. >18mm. Layer 5401, Group 457, Area J, Period 5-6

25. Not illustrated. Fragment, probably part of a small knife with the start of the tang. Slightly curved lengthwise. L. 44mm, max. W. 21mm. SF2282, Cleaning layer 5543, Area J, Period 5-6

26. Not illustrated. Broken knife tang, with the start of the blade. L. 54mm, W. of blade 16mm. SF2333, Layer 6212, Group 574, Area H, Period 4-5

27. Tanged knife, in good condition. It has a parallel-sided blade with a straight cutting edge, the back dipping to the point. The back is thickened on one face only. This is probably an example of the fairly rare Manning type 17. L. 145mm, L. of tang 52mm, W. of blade 22mm. SF2537, Machining layer 11000, Area A, unstratified

28. Not illustrated. Knife blade, parallel sided, with point and most of tang missing. The point of the knife may have been deliberately cut off, as it stops in a straight line. L. 110mm, W. 13mm. SF776, Machining layer 4000, Area A, unstratified

29. Not illustrated. Knife, point missing. Straight-backed, with the back in line with the tang. Manning type 11. L. 137mm, max. blade W. 37mm. SF6983, Cleaning layer 11345, Area N, not phased

30. Cylindrical copper-alloy knife handle, one side missing, and the butt end damaged. The blade end is bevelled, as with Greep's 'London type' (1982), with the narrow iron blade broken flush with the end of the handle. The tube was filled with a lead-based solder. The butt end has an iron plug, which is possibly the end of the tang, but which appears to be separate. However, all details of the tang are hidden by the solder. L 43mm, Diam. 13.5mm. SF129, Cleaning layer 3501, Area W, Period 3

31. Bronze. One piece knife handle with an oval section and waisted end. It has groups of moulded circumferential lines, and a completely perforating longitudinal hole. It is in fairly poor condition. A layer of bright metal plating shows in places, probably tinning. XRF showed that the object was a heavily leaded bronze throughout. L.52mm, Diam. 11.5-13mm. SF305, Machining layer 4000, Area A, unstratified

32. Copper-alloy dog and hare handle with an iron blade. L. 68mm, max. W. 25. SF834, Machining layer 4000, Area A, unstratified

33. Copper alloy. A roughly semi-circular plate with a hollow-backed, D-shaped stem, other end broken. There is a slit in the edge on one side of the stem, extending halfway round the head. The slit contains iron corrosion, apparently an iron plate fixed to the head by a rivet. On the back, on the edge without the slit, and at the junction between the head and stem, are two lugs, with an iron axis bar. The object is reminiscent of the terminal of an object from Wroxeter (Bushe-Fox 1914, 14, no. 19). The latter object has a moulded lion at one end, with lugs below, and a crescentic terminal at the other. Like the Elms Farm object, it had an iron blade (now missing) hinged into the terminal, although there were no lugs at this end. It was interpreted as the handle of a tool combining two implements. If, like the Wroxeter example, the Elms Farm object had a further implement at the missing end, it could be seen as the Roman equivalent of a Swiss Army knife. L. 19mm, W. of head 14mm, W. of stem 5mm, Th. of plate and stem 4mm, max. Th. 10mm. SF4685, Machining layer 11000

34. Socketed folding knife in two pieces, the socket (SF4164) and the blade (SF4163). There is recent damage to the socket, and the knife was obviously in one piece until excavation. The socket was made from a rectangular sheet with two semi-circular lugs at one end. The sheet was folded into a tube, with the edges almost butted, and the lugs were flattened to hold the blade, which was riveted on. Only one lug survives, but the shape of the second one is visible as a scar in the corrosion on the blade. There is a rivet through the base of the socket, to hold the missing handle. The outside of the socket has mineralised wood adhering, but this is probably not directly associated with the object. L. 136mm, blade L. 87mm, max. blade W. 28mm, socket L. 60mm. SF4163/4164, Cleaning layer 4881, Area K, not phased

35. Folding knife, in very poor condition, with the blade partly folded back against the iron handle ferrule. The socket has an internal diam. of 9mm, and has two opposed rivets visible near the end. There is a clear impression of the handle in the corrosion at the end of the socket, showing that it had a diameter c 3mm more than the internal diameter of the socket. There is a skin of mineralised wood in the socket, and the slit in the wood for the blade to slot into still survives. The ferrule is made from a sheet formed into a tube with the edges almost butted, as SF4163/4, with the end crimped to hold the butt end of the knife. The end of the tube and the lugs are missing, but the partial outline of one lug can be seen on the blade, round the pivot hole. The shape of the blade is clearer on the object than the X-ray, as the metal is very mineralised. Very little of the original edge survives, and the point and butt are damaged, but it probably had a straight edge and rounded back. L (folded) 69mm, max. external diam. of handle 13mm. SF5538, Fill 14093, Pit 14099, Group 4019, Area K, Period 4-5

This object is very similar to knife SF4163/4 (no. 34), and it transpires that part of the latter knife was found on top of Pit 14099. It is therefore almost certain that both came from the same pit.

36. Part of a folding knife, corroded onto a piece of tegula. The blade is complete, with a straight cutting edge and curved back. The handle, which is now at an angle to the blade, has two rounded lugs, flattened against the blade and pivoting on an iron rivet. Unlike the other folding knives from the site, the handle is tanged rather than socketed, but little of the tang survives. Blade L. 81mm, max. W. 21mm; lug W. 16mm, tang section 5x5mm. SF8466, Fill 8766, Pit 8745, Group 675, Area P, Period 5

37. Blade. The section is thin, with a curved back, and possibly the original point. The cutting edge is slightly scalloped. The butt end is complete as buried, and appears rounded, and possibly complete. This may be an unfinished blade from a folding knife, lacking its pivot hole. L. 74mm, max. W. 24mm. SF3567, Fill 5939, Pit 5940, Group 420, Area J, Period 4

38. Fragment, probably a rather blunt knife point, broken at the other end. L. 26mm, max. W. 7mm. SF6120, Fill 11340, Well 11341, Group 225, Area N, Period 4

39. Knife blade segment, with a pot rim corroded on, and a small globule of lead within the corrosion. L. 54mm, max. W. 18mm. SF2744, 5146, Pit 5147, Group 409, Area J, Period 3

40. Knife blade fragment, with a straight back and a rather rounded tip. L. 94mm, W. 16mm. SF6118, Fill 16230, Ditch 16231, Group 584, Area H, Period 6

41. Knife blade fragments, tang or socket missing. It has a straight back, with a regular taper to the point. L. 104mm, max. W. 20mm. SF1563, Layer 9264, Group 1302, Area D, not phased

42. Knife fragment; a narrow parallel-sided blade with a pointed tip, probably broken across a ring at the other end. Probably Manning type 1, possibly 1c. L. 112mm, W. 12mm. SF3179, Cleaning layer 5662, Area I, not phased

43. Knife blade point, with a fresh break. It has a straight edge and an angled back, as, for example, Manning type 4. L. 45mm, max. W. 16mm. SF4389, Cleaning layer 13028, Area I, not phased

44. Three joining strip fragments, probably a blade. The metal is very mineralised, and the edge is damaged. L. 74mm, max. W. 25mm. SF1183, Fill 4286, Pit 4285, Group 62, Area K, Period 2

45. The point from a large, thin blade, complete as buried. The surface is extensively covered in mineralised organic material, not directly associated with the object. The fragment is triangular, with a straight cutting edge. This large blade was probably a cleaver, similar to Manning Q103. L 178mm, W 82mm. SF2869, Fill 4521, Pit 4522, Group 275, Area K, Period 2

46. Blade fragment, fresh break. L. 28mm, W. 22mm. SF2819, Fill 7195, Pit 7221, Group 311, Area G, Period 2

47. Blade fragment, with a straight back, the edge curving evenly to the point. The tang or socket is completely missing. The blade is quite substantial, originally about 6mm across the back, and is probably from a heavy duty blade such as a chopper rather than an ordinary knife. L. 90mm, max. W. 32mm. SF6209, Fill 6828, Ditch 16018, Group 63, Area H, Period 2A

48. Probable blade fragment. The section is very thin, with neither side edged. One end has an old break, the other has an asymmetric point. The shape is right for a knife blade with a straight cutting edge, but it was either extremely blunt when buried, or is perhaps part of an unfinished implement. SF2118, Fill 5430, Pit 5431, Group 24, Area J, Period 2A

49. Fragment from the tip of a parallel-sided blade. The point is rather abrupt, with a ?broken tang at right-angles to the point. This is possibly part of a currier's slicker. See Manning 1985a, 39, E1-2 for two Late Iron Age examples. L. 37mm, W. 20mm. SF7870, Layer 20210, Group 113, Area L, Period 2B

50. Blade point, damaged. The break is very straight and sharp, and this was possibly cut in antiquity. Parallel sided, with an angled tip as Manning knife type 1c or 2. L. 69mm, W. 22mm. SF1979, Fill 4537, Pit 4536, Group 730, Area K, Period 3

51. Blade fragment, with fresh breaks. L. 43mm, max. W. 20mm. SF2795, Fill 8167, Well 8188, Group 788, Area E, Period 3

52. Socketed blade fragment, in two fragments, with the end of the socket and most of the blade missing. The back is straight and thick, 4mm. wide. L. 70mm, blade W. >32mm. In good condition. SF6919, Fill 8167, Well 8188, Group 788, Area E, Period 3

53. Blade fragment. L. 49mm, W. 17mm. SF7720, Fill 8537, Pit 8524, Group 656, Area P, Period 3

54. Two joining fragments of a parallel-sided blade. L. 73mm, W. 32mm. SF5201, Fill 10523, Ditch 10522, Group 360, Area F, Period 3

55. Blade fragment, in two pieces. 78x28mm. SF8298, Fill 13725, Pit 13824, Area I, Period 3

56. Blade fragment, fresh breaks either end. L. 40mm, W. 15-18mm. SF2122, Fill 10095, Pit 10094, Group 831, Area F, Period 4

57. Blade point, possibly part of SF7227, but damaged at the break, and with a clear cutting edge, unlike SF7227. The point is rather rounded. L. 76mm, W. 24mm. SF7225, Fill 11305, Pit 11304, Group 674, Area N, Period 4

58. Tanged blade with the tang set in line with the ?back of the blade. The end of the tang and the point are missing, and the blade is bent back on itself. There is no clear cutting edge, although Vanessa Fell notes that it is much damaged through corrosion. Blade W. 25mm, original L. c. 70mm, tang 20x9x3mm. SF7227, Fill 11305, Pit 11304, Group 674, Area N, Period 4

59. Blade fragment. L. 25mm, W. 20mm. SF8270, Fill 8153, Pit 8155, Group 836, Area E, Period 5

60. Fragment, possibly the point from a straight-backed blade. 52x28mm. SF8053, Layer 10255, Group 840, Area F, Period 5

61. Blade fragment with a thickened back, possibly part of a sickle. L. 43mm, W. 23mm. SF7700, Fill 10877, Pit 10910, Group 676, Area N, Period 5

62. Blade fragment, possibly with a slightly reinforced back. L. 47mm, W. 224mm. SF8217, Fill 5300, Pit 5282, Group 437, Area J, Period 5

63. Probable curved blade fragment, possibly part of a small pruning hook. L. 50mm, max. W. 18mm. SF3348, Fill 5864, Pit 5805, Group 444, Area J, Period 6

64. Fragment, probably the point of a blade. The section is triangular, although the 'edge' is now rather blunt. L. 45mm, max. W. 24mm. SF7724, Fill 9382, Ditch 9381, Group 834, Area D, Period 5-6

65. Open socket, most of the blade missing. The blade was probably single-sided. L. 64mm, socket W. 18mm, blade W. 18mm. SF3525, Layer 5809, Group 8003, Area J, not phased.

66. Blade fragment, from near the tip. L. 34mm, W. 16mm. SF432, Cleaning layer 6000, Area H, not phased.

67. Probable blade fragment, broken across the start of the tang. Blade edge damaged. L. 55mm, W. 35mm. SF500, Machining layer 7000, Area G.

68. Blade fragment, parallel-sided, with rather rounded tip. L. 112mm, W. 23mm. SF3302, Layer 9513, Group 1001, Area D, not phased

69. Two joining fragments, probably part of a blade. The tip may be rounded. L. 42mm, W. 23mm. SF5601, Cleaning layer 10682, Area F, not phased

70. Probable blade segment, parallel sided. L. 45mm, W. 21mm. SF764, Machining layer 4000, Area A, unstratified

Shears (Figure 545) seem curiously under-represented at Elms Farm, with only two pairs, neither of which is from a well-stratified context. However, it is difficult distinguishing between fragments of shear blades and knife blades.

71. Not illustrated. Part of a pair of shears. Half the blade is missing, and the handle is broken below the loop. L. 75mm, blade W. 18mm. SF383, Machining layer 4000, Area A, unstratified

72. A pair of shears, in three pieces. The basic shape is not unusual for Roman shears, although the handle on this example is unusually short. L. 182mm, handle L. 48mm. SF5133, Cleaning layer 5597, Area I, not phased

One definite and one possible trowel were found (Figure 545). Neither is complete enough to be certain of its original shape.

73. Tanged trowel, blade incomplete. The blade was probably a narrow leaf-shape (Manning type IV; Manning 1976, 27), and would probably have been used for fine plasterwork. The vertical between the blade and tang is broad, being a simple continuation of the blade bent at right angles. SF7419, Fill 15857, Pit 15856, Group 698, Area M, Period 5

74. Not illustrated. Tanged object, with part of a ?blade at right-angles. This is probably a trowel tang, broken at the top of the vertical element of the tang, and also across the beginning of the blade. The bottom of the tang broadens slightly. L. 65mm, max. W. of tang 16mm. Layer 10492, Group 838, Area F, Period 5-6

Two types of iron awl were present on the site (Figure 545), those designed to be inserted into wood or bone handles, normally tapering at both ends, and those with broader butts that may have been used without a separate handle. Awls are a particularly difficult tool to recognise, as the larger examples resemble drill bits, and incomplete examples may simply look like nail fragments. Examples with pointed tips are probably leatherworkers' awls, while those with chisel tips are carpenters' bradawls. Of the nine definite or probable awls, two are bradawls, and the remainder probably leatherworking awls.

75. Awl, tapering either end, with a ?rounded tip, other end broken. Comparable to Manning 1985a, E14, although the Elms Farm example appears to have a rectangular section rather than the more usual square section. L. 128mm, max. W. 11mm. SF7516, Layer 20303, Group 113, Area L, Period 2B

76. Not illustrated. Awl or small drill bit, probably with a square section throughout. The tip is bent. L. 68mm, max. W. 5mm. Fill 14022, Pit 14098, Group 4019, Area K, Period 4-5

77. Small tanged ?bradawl. Rectangular section with a chisel point of the same width, and a short tang. L. 45mm, section 4x3mm, tang L. 9mm. SF1640, Fill 6117, Pit 6127, Group 577, Area H, Period 5

78. Not illustrated. Probable awl. Rod, section unknown, with one end pointed, the other broken in antiquity. The shaft is swollen. L. 67mm, max. W. 4mm. Cleaning layer 5305, Area J, Period 5-6

79. Large awl, circular section. One end tapers to a blunt point. The other end is square in section, with a constriction 36mm from the end. The tip is turned at right angles. Manning type 4b, similar to Manning E12. L. 272mm, max. W. 12mm. SF1096, Machining layer 7000, Area G

80. Awl, with a square section, tapering to a point at one end and with a very narrow chisel point at the other. The latter feature identifies it as a carpenter's bradawl rather than a leatherworker's awl. L. 89mm, max. W. mm. Layer 7073, Group 1319, Area G, not phased

81. Small awl or drill bit. Rectangular sectioned, swollen shaft, tip missing. L. 48mm. Unknown context 13801, Area J, not dated

82. Not illustrated. Small bar, tapering at both ends, completeness uncertain. This might be a small awl. L. 36mm, max. section 3x3mm. SF6455, Unknown context 13801, Area J, not dated

83. Tool, probably an awl, with the very tip missing and the butt probably incomplete. It has a notch with a V-shaped profile across one face at the butt end. The section is rectangular, possibly slightly rounded in the middle. Machining layer 2000, Area W, unstratified

Two bone awls (see Figure 545) were identified, one belonging to Danebury Class 2 (SF8397), and one to Danebury Class 4 (SF6833) (Sellwood 1984, 389). Although their form is consistent with use as boring implements, their precise function is unknown. They were possibly used in leather-working, although they do not appear to be robust enough to pierce leather of any thickness.

84. Awl, made from a pointed splinter of a large mammal long bone. Slight damage to the butt, surface eroded. L. 65mm, W. 21mm. SF6833, 4692, Slot 4695, Group 1161, Area K, not phased

85. An ?awl, made from a horse fibula. Complete bar the point. The surface is in fair condition, with no definite sign of wear, so this may not have been used. L. 89mm, Diam. 24mm tapering to 7mm. SF8397, Layer 6959, Group 484, Area H, Period 3

Chisels are the most common tool type recognised on the site, with forty-three examples. Twenty-eight of these are definite or probable 'simple' chisels, as Manning B43 and B44. These have short tangs, usually with a square section, and small triangular or semicircular blades, often bevelled on one face only. The type was undoubtedly far more common, as broken simple chisel tangs are indistinguishable from nail shafts. Some of the broken blades could possibly be styli, but where the tang section is clearly square, it has been assumed to be a chisel. The 'simple' chisels can be Iron Age or Roman, but there are only two examples from Iron Age contexts at Elms Farm.

The other chisels include several hot chisels, for use in iron working, as well as socketed and tanged carpenters' chisels.

86. Not illustrated. Probably a simple chisel with the blade bent at right angles to the tang. L. 48mm, L. unbent 67mm, blade W. 11mm. SF5430, Fill 14002, Post-hole 14057, Group 92, Area K, Period 2

87. Not illustrated. Possible small simple chisel blade, the shank slightly bent, and broken in antiquity. It has a narrow triangular blade. L. 23mm, blade W. 6mm. Fill 2264, Ditch 2265, Group 10, Area W, Period 2A

88. Not illustrated. Probable simple chisel. In two pieces, tang incomplete. L. 52mm, blade W. 17mm. Layer 5936, Group 606, Area I, Period 3B

89. Not illustrated. Simple chisel, broken square-sectioned tang. Quite a chunky little chisel. L. 40mm, blade W. 21mm. Layer 6121, Group 556, Area H, Period 4

90. Not illustrated. Simple chisel, shaft broken. L. 42mm, blade W. 16mm. Layer 6142, Group 543, Area H, Period 4

91. Not illustrated. Probable small, tanged chisel, with a slightly splayed, rather elongated blade. Probably incomplete. Square-sectioned tang, blade W. c. 8mm, L. 73mm. Layer 21908, Group 423, Area J, Period 4

92. Not illustrated. Simple chisel, complete. L. 45mm, blade W. 9mm. Fill 14093, Pit 14099, Group 4019, Area K, Period 4-5

93. Not illustrated. Possible distorted simple chisel. The shaft is complete and bent, with the head curved back on itself. The head is clearly flattened, and probably flared, although no details are visible on the X-ray. L. 49mm, head W. c. 14mm. Fill 5229, Post-hole 5232, Group 427, Area J, Period 4-6

94. Not illustrated. Possible simple chisel, with a rather narrow inverted triangular head. The shank is curved, and was broken in antiquity. L. 43mm, head W. 8mm. Fill 5472, Ditch 5473, Group 436, Area J, Period 5

95. Not illustrated. Two possible simple chisels, with the heads bent over. a) incomplete shaft, L. 33mm, head W. 16mm b) complete. L. 47mm, head W. 15mm. Fill 10502, Pit 10504, Group 846, Area F, Period 4

96. Not illustrated. Probable simple chisel. The point of the tang is missing, and the blade probably incomplete. L. 58mm, blade W. 16mm. Fill 11139, Pit 10910, Group 676, Area N, Period 5

97. Not illustrated. Possible simple chisel, with the tip of the tang missing. L. 40mm, W. of blade 9mm. Cleaning layer 5543, Area J, Period 5-6

98. Not illustrated. Possible simple chisel. It resembles a slightly flaring stylus eraser, but the broken shaft has a square section, so it is more likely to be a chisel. L. 38mm, W. of blade 7mm. Fill 5864, Pit 5805, Group 444, Area J, Period 6

99. Not illustrated. Probable simple chisel head. L. 53mm, head W. 14mm. SF3327, Fill 5864, Pit 5805, Group 444, Area J, Period 6

100. Not illustrated. Possible simple chisel blade. A very blunt triangular blade with a short tang, probably broken in antiquity. L. 38mm, blade W. 17mm. Dump 6786, Group 586, Area H, Period 5-6

101. Not illustrated. Probable simple chisel with the blade bent back on itself and the shank distorted. L. 50mm, max. W. 16mm. Fill 14635, Pit 14632, Group 722, Area L, Period 6

102. Not illustrated. Simple chisel, with a roughly semi-circular blade, curved edge to the tang. The edge is incomplete and damaged. Cf. Manning 1985a, 24, nos B43 and B44. SF6648, Layer 15462, Group 751, Area M, Period 5-6

103. Not illustrated. Simple chisel, with incomplete square shaft. L. 52mm, W. of blade 20mm. SF838, Machining layer 4000, Area A, unstratified

104. Not illustrated. Simple chisel, with the end of the tang and one corner of the blade missing. The blade is triangular, with slightly rounded sides. L. 53mm, original blade W. c. 20mm. SF6595, Machining layer 4000, Area A, unstratified

105. Small simple chisel, as Manning 1985a, B43/44. L. 62mm, blade W. 12mm. SF8213, Machining layer 4000, Area A, unstratified

106. Not illustrated. Small simple chisel, with the end of the tang missing. L. 33mm, blade W. 8mm. Fill 4842, Pit 4843, Group 1147, Area K, not phased

107. Not illustrated. Simple chisel. The blade is relatively elongated for the type, although still an inverted triangle, with very slight shoulders onto the tang. Complete. L. 45mm, blade L. 20mm, W. 9mm. Machining layer 7000, Area G, Not phased

108. Not illustrated. Simple chisel. The edge of the blade is bevelled and the tang incomplete. L. 43mm, blade W. 15mm. Machining layer 7000, Area G, Not phased

109. Not illustrated. Possible simple chisel. The shaft is broken, and the head flattened into a small, rounded blade. L. 43mm, head W. 10mm. Cleaning layer 10242, Area F, not phased

110. Not illustrated. Simple chisel. A small triangular blade with 2mm of the edge turned at right angles. The end of the tang is missing. L. 49mm, blade W. 12mm. SF5242, Cleaning layer 10506, Area F, not phased

111. Not illustrated. Probable simple chisel, with the head bent over. L. 50mm, blade W. 17mm. Cleaning layer 10978, Area N, not phased

112. Simple chisel, complete, with the end of the tang bent. L. 61mm, blade W. 16mm. Cleaning layer 23002, Area N, not dated (Figure 545)

113. Simple chisel, with a D-shaped blade, bevelled on one face only. Complete. L. 45mm, blade W. 11mm. Cleaning layer 24058, Area M, not phased (Figure 545)

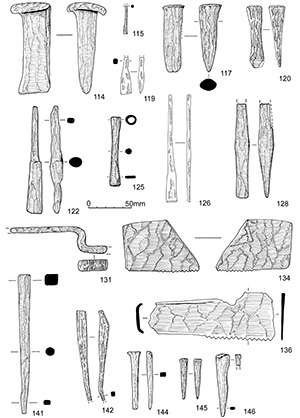

114. Chisel or wedge. The edge is slightly splayed and somewhat blunt. The top is burred on three sides. L. 108mm, section c. 33x22mm. SF6668, Fill 15290, Pit 15573, Group 691, Area M, Period 3

115. Rod, with a circular section and a slightly flared, flattened terminal, other end broken. This is probably a simple tool of the type described at Danebury as a chisel made from a small iron rod (Sellwood 1984, 354, nos 2.60-2.62). It differs from the simple chisels listed above in that the tang has a circular section. L. 34mm, blade W. 6mm. SF6119, Fill 15612, Pit 15641, Group 240, Area M, Period 2B

116. Not illustrated. Bar with closed socket, end of bar broken. Probably a chisel, cf Manning B36. L. 90mm, max. socket Diam. 18mm, bar W. 17mm, Th. 2.5mm. SF902, Layer 6053, Group 506, Area H, Period 3

117. Chisel or punch. Oval section, with a burred head and a broad wedge point. L. 84mm, section c. 18x18mm. SF1061, Layer 5494, Group 631, Area I, Period 3B

118. Not illustrated. Bar fragment, one end broken in antiquity and slightly bent. The other end is bevelled. Probably a damaged chisel blade. L. 48mm, W. 11mm, Th. 7mm. SF3288, Fill 9344, Gully 9343, Group 3063, Area D, Period 3-4

119. Probable small chisel with a triangular blade, which Vanessa Fell notes is worn. The short tang is possibly incomplete. L. 44mm, blade W. 14mm. SF7638, Spread 10289, Group 820, Area F, Period 4

120. A small hot chisel. The short, solid handle has a circular top, diam. 18mm, tapering fairly abruptly to a slightly splayed blade, tip damaged in antiquity. L. 70mm, blade W. 17mm. SF2751, Layer 6238, Group 574, Area H, Period 4-5

121. Not illustrated. Chisel blade or wedge. The thin end is slightly splayed, and was damaged in antiquity, making it impossible to say whether the edge was bevelled. In good condition, and apparently complete as buried. L. 60mm, W. 13mm, max. Th. 15mm. SF4647, Fill 10502, Pit 10504, Group 846, Area F, Period 4

122. Chisel, probably a tanged paring chisel, with a bolster between the blade and the tang. Cf. Manning 1976, 25 no. 59. L. 128mm. SF3209, Make-up layer 5499, Group 434, Area H, Period 5

123. Not illustrated. Socketed object. It has a narrow, closed socket, gaping slightly along the seam, and a broken shank with a rectangular section. This is probably a chisel, with the blade missing. Overall L. 76mm, socket L. 45mm, diam. 12mm, shank section 9x6mm. Fill 5214, Pit 5209, Group 442, Area J, Period 6

124. Not illustrated. Socketed bar, with fresh break. There may be mineralised wood present in the open socket. Probably part of a socketed chisel. Socket L. 47mm, diam. 20mm; bar diam. 7mm. Overall L. 145mm. SF894, Layer 6025, Group 573, Area H, Period 5-6

125. Chisel, with a closed socket, slightly damaged but with a complete length. The blade is slightly splayed. L. 80mm, W. of blade 14mm, diam. of socket 12mm. SF1771, Cleaning layer 5228, Area J, Period 5-6

126. Chisel. A square sectioned tang and rectangular sectioned blade with a chamfered end. A carpenter's paring chisel, similar to Manning B30. L. 124mm, W. 13mm. SF7239, Layer 15613, Group 6009, Area M, Period 6

127. Not illustrated. Tanged chisel with a slightly flared point, probably bevelled. Cf. Manning B30. L. 93mm, W. of blade 17mm. SF1428, Machining layer 4000, Area A, unstratified

128. Chisel, head probably burred. It has a thin, parallel-sided blade, with an expansion in the middle of the shank. Manning suggests that this form is a hot chisel, cf. Manning 1985a, A21. L. 112mm, W. 15mm, max. Th. 16mm. SF5691, Machining layer 11000, Area A, unstratified

There was only one definite drill bit identified, a small fragment of a spoon bit from a Period 4-5 context. A second fragment, from a Period 5-6 layer is possibly the stem of a drill bit.

129. Not illustrated. Possible drill bit, both ends broken. The broader end is probably starting to narrow again, suggesting that this is not just a nail shaft. L. 109mm. SF875, Layer 6008, Area H, Period 5-6

130. Not illustrated. Spoon bit, stem missing. It is possible that one of the 'nail shafts' from the context is part of this object, but the break is ancient, and although it was corroded onto several other pieces of iron, none of them joined. Oval, L. 29mm, W. 10mm. Fill 14093, Pit 14099, Group 4019, Area K, Period 4-5

131. File, with cranked tang. The tang has a fresh break, the blade an ancient one. The blade has a rectangular section, and the teeth are single cut and raked, with 5.5 teeth to the centimetre. The file is thus coarse cut, suggesting that it may be a carpenter's float rather than a metalworking file (cf. Manning B79). L. 104mm, L. of blade 31mm, section 11x9mm. SF404, Fill 4142, Pit 4141, Group 1147, Area K, unphased (Figure 546)

132. Not illustrated. Gouge, with a solid, circular-sectioned handle of constant diameter with a slightly burred head. The U-shaped tip is incomplete. L. 79mm, Diam. 9mm. SF1159, Fill 4129, Pit 4128, Group 744, Area K, Period 6

133. Not illustrated. Bar fragment, probably part of a gouge. The end is flattened, with a very shallow curve. L. 39mm, W. 7mm. Cleaning layer 14201, Area L, not phased

134. Saw blade fragment in two pieces, from a fairly wide handsaw. There are no teeth visible for the first 24mm, so this is presumably from near the handle end, although there are no perforations present. The teeth are slightly raked, but not set, with c. 3 teeth per cm. One corner of the back is turned over. L. 90mm, W. 59mm. SF4718, Fill 13290, Pit 13358, Group 645, Area I, Period 5 (Figure 546)

135. Not illustrated. A small fragment from a saw blade, with four teeth present, probably not set. The teeth are symmetrical, which Manning (1985a, 21) suggests marks it as a bow saw. L. 18mm, W. 21mm. SF8315, 16270, Hearth construction 16273, Group 587, Area H, Period 6

136. Handsaw fragment, in two joining pieces, broken in antiquity. It has rather irregular teeth, which are not set, with 2.5 teeth to 2cm. The handle has a low flange along each edge. There are no definite nail holes, but the metal is very mineralised and patchy on the X-ray. L. 144mm, W. 53mm. SF7349/6139 Fill 20063, P it 20066, Group 707, Area L, Period 3 (Figure 546)